3

TRUE

tcgr www.truemfg.com

OWNERSHIP

To ensure that your unit works properly from the first day, it must

be installed properly. We highly recommend a trained refrigeration

mechanic and electrician install your TRUE equipment. The cost of a

professional installation is money well spent.

Before you start to install your TRUE unit, carefully inspect it for

freight damage. If damage is discovered, immediately file a claim with

the delivery freight carrier.

TRUE is not responsible for damage incurred during shipment.

UNCRATING

TOOLS REQUIRED

• Tin Snips / Band Cutters

• Claw Hammer

• Hex Head Driver

• Adjustable Wrench

• 3/4" (19 mm) Open-End Wrench

• Phillips Screwdriver

• Level

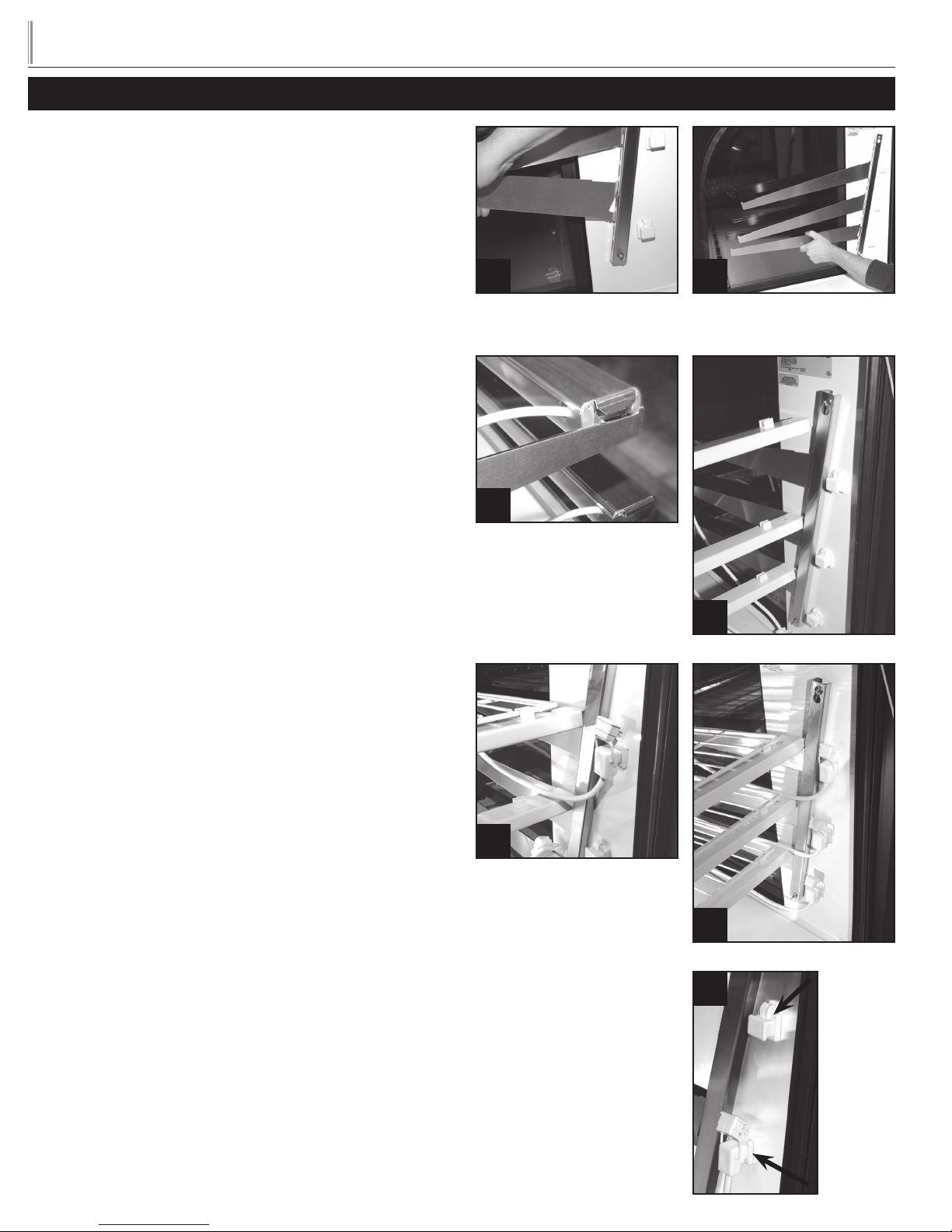

The following procedure is recommended for uncrating the unit:

A. Cut metal retaining straps securing protective top skid. Remove

the outer packaging by pulling tri-wall nails from skid. Remove

(4) cardboard corner pads and dust cover.

B. Inspect for concealed damage. Again, immediately file a claim

with the freight carrier if there is damage.

C. Move your display case as close to the final location as possible

before removing the wooden skid.

NOTE: KEYS FOR COOLERS WITH DOOR LOCKS

ARE LOCATED IN WARRANTY PACKETS.

INSTALLATION

ELECTRIC INSTALLATION & SAFETY

INFORMATION

Hard wiring for a 30 amp circuit is required on specific Display Cases.'

Models standard with power cords: Do not, under any circumstances, cut

or remove the ground prong from the power cord. For personal safety, this

appliance must be properly grounded.

• If the supply cord is damaged, it must be replaced by a special

cord or assembly available from the manufacturer or its service

agent.

• Lamps must be replaced by identical lamps only.

• Appliance tested according to the climate classes 5 and 7

temperature and relative humidity.

ELECTRICAL INSTRUCTIONS

A. Before your new unit is connected to a power supply, check the

incoming voltage with a voltmeter. If anything less than 100% of

the rated voltage for operation is noted, correct immediately.

B. All units equipped with a service cord must be powered at

proper operating voltage at all times. Refer to cabinet data

plate for this voltage.

TRUE RECOMMENDS THAT A SOLE USE CIRCUIT BE

DEDICATED FOR THE UNIT.

WARNING: Compressor warranties are void if compressor burns

out due to low voltage.

WARNING: Power supply cord ground should not be removed!

WARNING: Do not use electrical appliances inside the food stor-

age compartments of the appliances unless they are of the type

recommended by the manufacturer.

NOTE: To reference wiring diagram, remove front louvered grill,

wiring diagram is positioned on the inside cabinet wall.

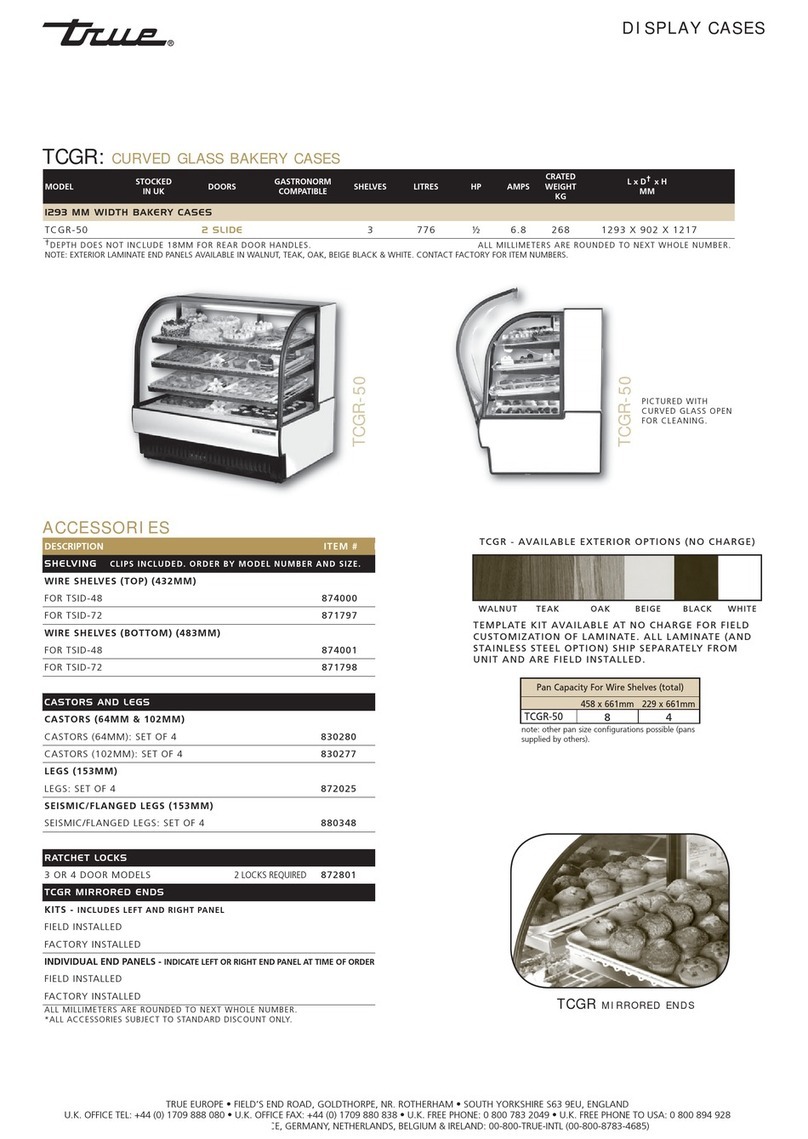

CURVED GLASS DISPLAY CASES

Some cases are equipped with a service receptacle, found on the

upper right cabinet and backside. No electrical load greater than 4-5

amps should be connected to this receptacle. Maximum Amp load is

listed on the label next to the service receptacle.

FOR REFERENCE ONLY