............ www.truemfg.com ............

True Food Service Equipment, Inc.

33

Beforeyournewdisplaycaseisconnectedtoapower

supply,checktheincomingvoltagewithavoltmeter.

Ifanythinglessthan100%oftheratedvoltagefor

operationisnoted,correctimmediately.

Havethecircuitcheckedbyaqualifiedelectricianto

makesureitisproperlygrounded.

Thedisplaycaseshouldalwaysbeuseit’sownindividual

electricalcircuit,whichhasavoltageratingthatmatches

theratingplate.

Thisprovidesthebestperformanceandalsoprevents

overloadingbuildingwiringcircuitswhichcouldcausea

firehazardfromoverheatedwires.

For models with Optional 12" (30.5 cm) cord.

Thepowercordofthisapplianceisequippedwitha

groundingplugwhichmateswithastandardgrounding

walloutlettominimizethepossibilityofelectricshock

hazardfromthisappliance.

Havethecircuitcheckedbyaqualifiedelectricianto

makesureitisproperlygrounded.

Iftheoutletisastandard2-prongoutlet,itisyour

personalresponsibilityandobligationtohaveitreplaced

withtheproperlygroundedwalloutlet.

Thedisplaycaseshouldalwaysbepluggedintoit’sown

individualelectricalcircuit,whichhasavoltagerating

thatmatchestheratingplate.

Thisprovidesthebestperformanceandalsoprevents

overloadingbuildingwiringcircuitswhichcouldcausea

firehazardfromoverheatedwires.

Neverunplugyourdisplaycasebypullingonthepower

cord.Alwaysgripplugfirmlyandpullstraightoutfrom

the outlet.

Repairorreplaceimmediatelyallpowercordsthathave

becomefrayedorotherwisedamaged.Donotuseacord

thatshowscracksorabrasiondamagealongitslengthor

at either end.

Whenremovingthedisplaycaseawayfromthewall,be

carefulnottorolloverordamagethepowercord.

HOW TO CONNECT ELECTRICITY

Hard wiring is required on standard "Dry" Display Cases.

Optional 12" (30.5 cm) corded model available, factory installed only

(exterior scale receptacle will not be included with this option).

WARNING!

NOTE

Applies to models ordered with 12" power

cord, hard wired models do not use this

receptacle.

USE OF ADAPTER PLUGS

NEVER USE AN ADAPTER PLUG! Because of potential safety hazards under certain conditions, we strongly recommend

against the use of an adapter plug.

SAFETY INFORMATION

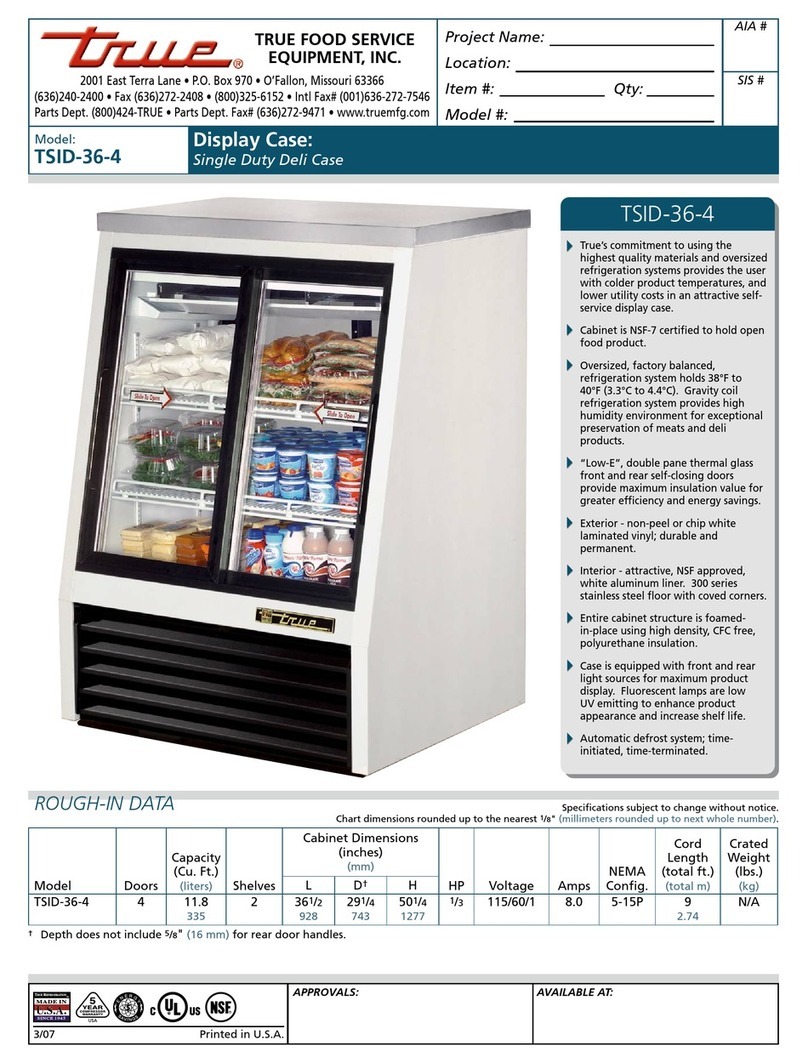

NEMAplugs

TRUEusesthesetypesofplugs.If

youdonothavetherightoutlethave

acertifiedelectricianinstallthecorrect

power source.

115/60/1

NEMA-5-15R

Theincomingpowersourcetothecabinetincludinganyadaptersusedmusthavetheadequatepoweravailableand

mustbeproperlygrounded.OnlyadapterslistedwithULshouldbeused.