Table of Contents

1. Introduction .......................................................................................................................................................................................................4

1.1 Product Specification...................................................................................................................................................................................5

1.2 Printer Optional Features.............................................................................................................................................................................6

1.3 General Specification...................................................................................................................................................................................7

1.4 Print Specification........................................................................................................................................................................................7

1.5 Media Specification......................................................................................................................................................................................8

2. Operation Overview...........................................................................................................................................................................................9

2.1 Unpacking and Inspection............................................................................................................................................................................9

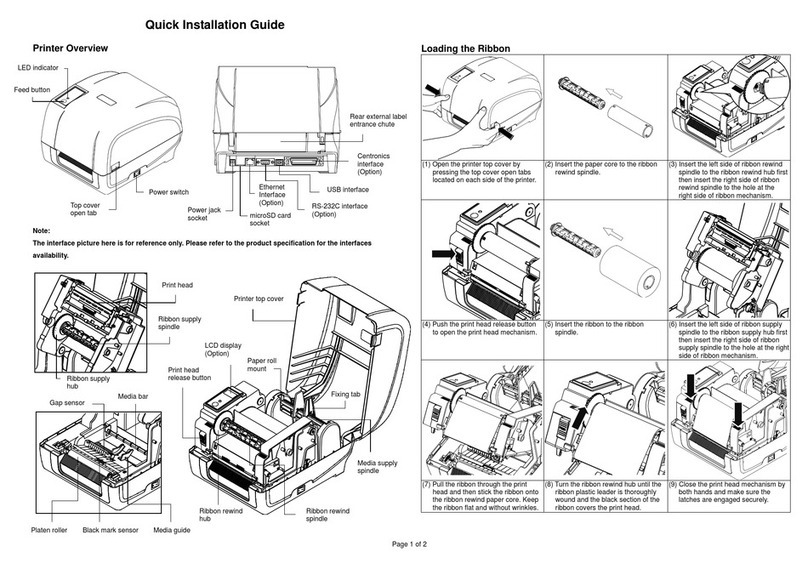

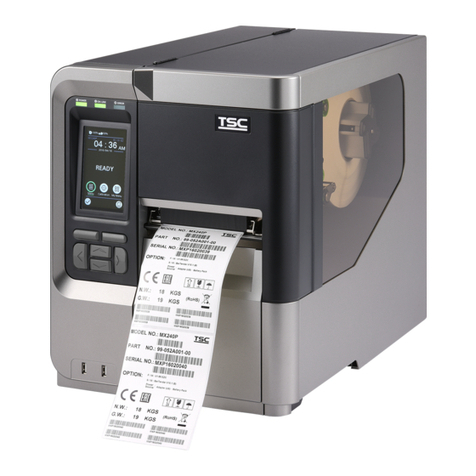

2.2 Printer Overview ........................................................................................................................................................................................10

2.2.1 Front View...........................................................................................................................................................................................10

2.2.2 Interior View ........................................................................................................................................................................................11

2.2.3 Rear View............................................................................................................................................................................................12

3. Setup...............................................................................................................................................................................................................13

3.1 Setting up the Printer.................................................................................................................................................................................13

3.2 Loading the Media .....................................................................................................................................................................................14

3.2.1 Loading the External Media.................................................................................................................................................................15

3.2.2 Loading Media in Peel-off Mode (Option for DA220 series).................................................................................................................16

3.2.3 Loading the Media in Cutter Mode (Option).........................................................................................................................................17

3.3 Install the Adapter for 1.5” Paper Core (Option) .........................................................................................................................................18

4. LED and Button Functions...............................................................................................................................................................................19