2CG-5519 CalGym - Ab Crunch #150

Introduction

About the CG-5519 CalGym - Ab Crunch #150

Congratulations on your new purchase of the CalGym -Ab Crunch

#150. We hope you are completely satisfied with this product and

wish you many years of enjoyment.

TuffStuff Equipment

ThisTuffstuffproducthasbeenbuilttoprecise quality standardsand

has been carefully packaged to ensure that damage will not occur

during shipment. The TuffStuff Warranty and signature indicating

final inspection has been conducted by our line foreman, is an

expression of our confidence in the completeness, the materials,

and workmanship of this product.

Warranty

SEE A COPY OF WARRANTY ON BACK PAGE.

Registration Card

To avoid unnecessary delays in warranty service and to insure that

a permanent record of your purchase is on file with our factory,

be sure to complete the warranty registration card and send it to

TuffStuff Fitness Equipment today.

Prior to the Assembly of the CalGym - Ab Crunch #150

We advise you to consult your local TuffStuff retailer if you should

have a question or problem regarding the proper assembly of this

unit.

Tool Requirements

One 7/8” combination wrench1.One 3/4” combination wrench2.One 9/16” combination wrench3.One 1/2” combination wrench4.One 7/16” combination wrench5.One adjustable wrench6.One ratchet7.One 3/4” socket8.One 9/16” socket9.Rubber Mallet10. Windex or household glass cleaner11. Measuring tape12. Utility knife13.

Note: Due to continuing product improvements, specifications and designs are subject to change

without notice.

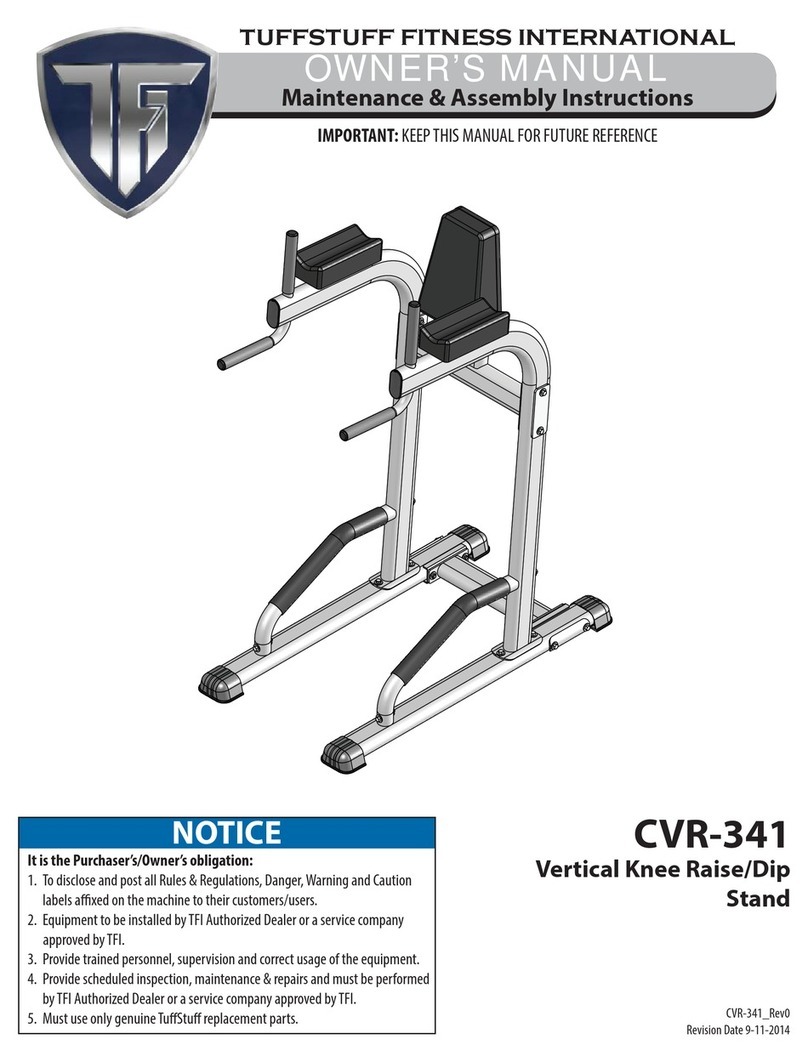

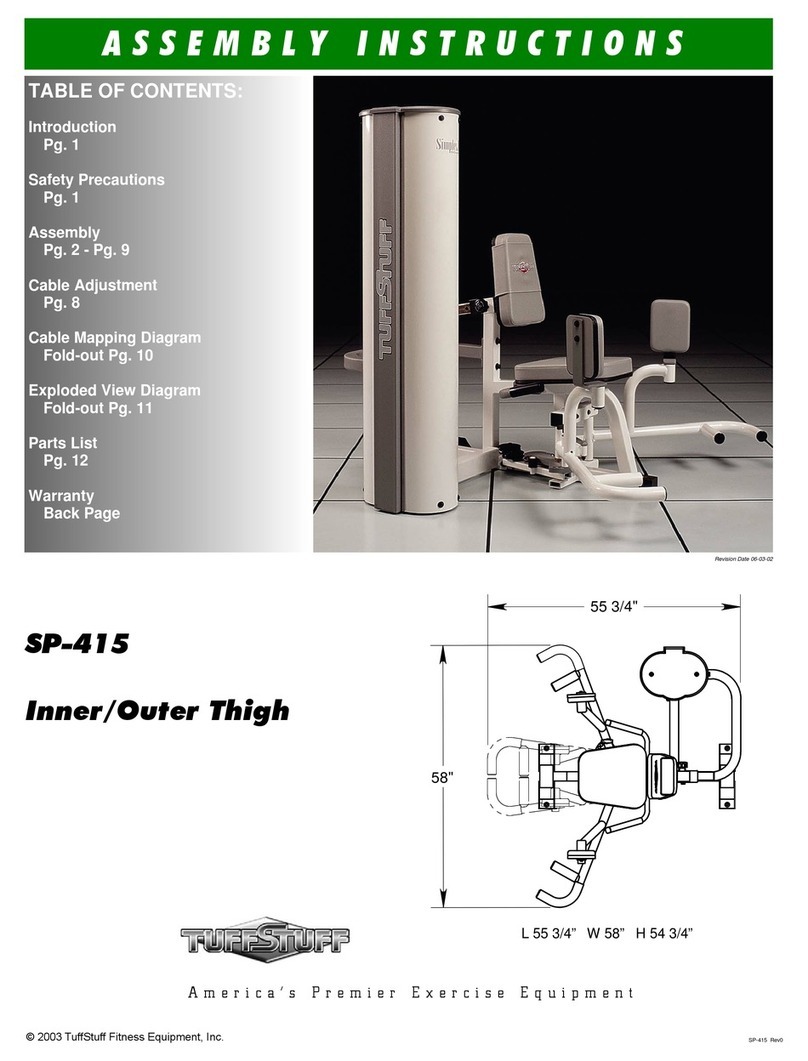

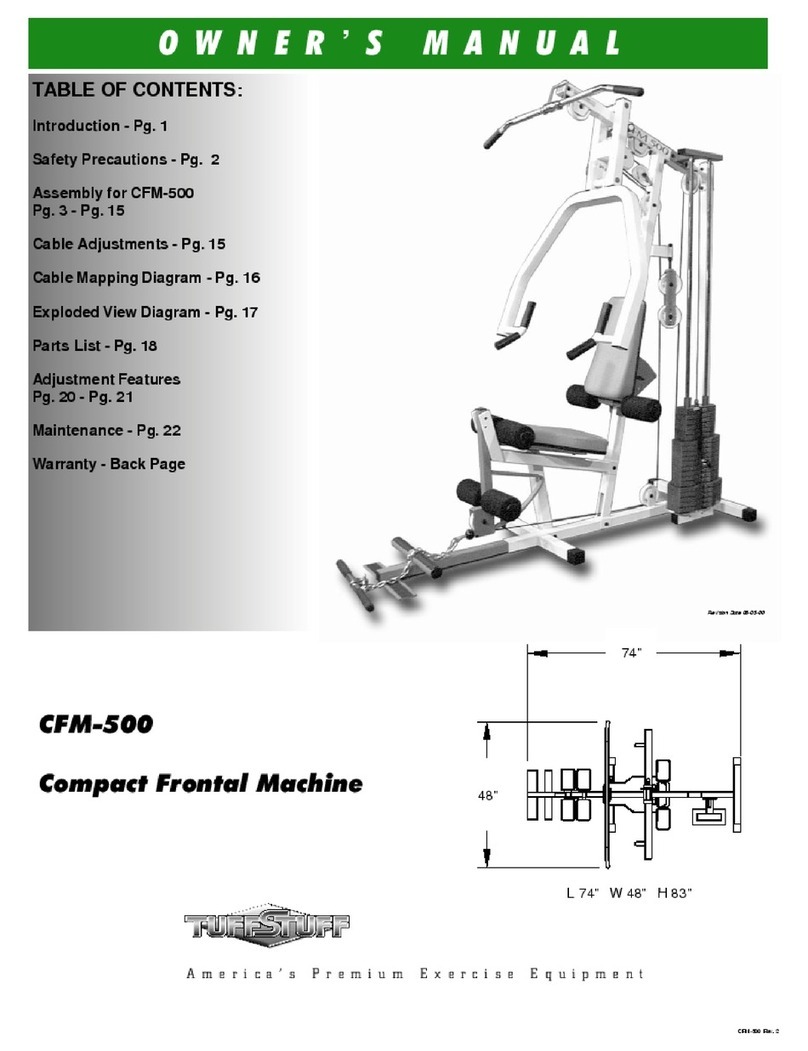

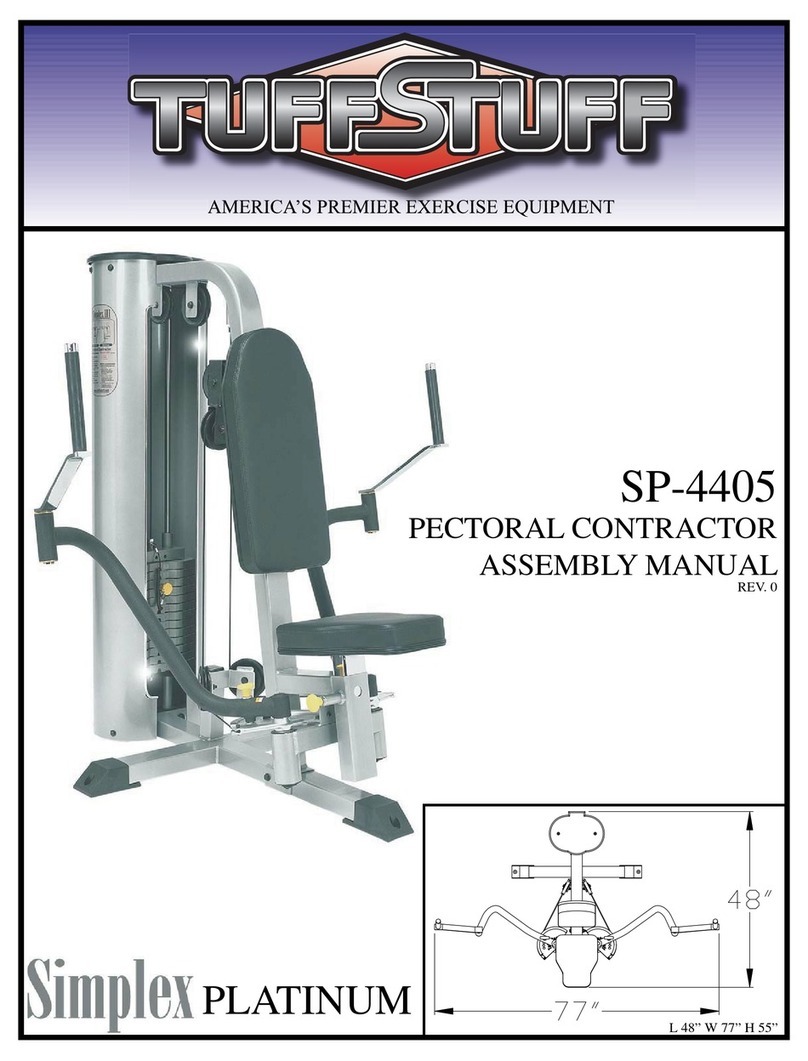

Specifications

1. Maximum Wt. Capacity - 150 lbs. fixed

2. Total Machine Weight - 365 lbs.

3. Footprint (LWH) - See Front Cover.

SCREWWIDTH

WASHERDIAMETER

NUTDIAMETER

SCREWLENGTH

Hardware Measurement Diagram

TuffStuff Basic Strength Equipment Safety and General Maintenance

All TUFFSTUFF strength equipment is designed and manufactured to offer maximum, long-life service with minimal

maintenance. However, safety inspection and routine maintenance in your facility should be the upmost importance

in your daily operation. Information presented in these pages will serve as a basic guideline to design your own

inspection procedures.

Part One: General Inspection and Cleaning

Equipment should be wiped down with a damp cloth and dried on a daily basis. The powder coat finish should be

polished with a good car wax on a monthly basis. A daily wipe down of the upholstery with a lanolin based hand

cleaner or Naugahyde Cleaner. Do not use cleaners such as Lysol or Windex as they will dry out and crack the

vinyl. Lanolin hand cleaner dissolves the sweat and lubricates the vinyl, maintaining its natural flexibility. Sweat

is corrosive and when left on the frame and components will eventually cause corrosion or rust. When performing

these cleaning sessions, it is the perfect time to inspect the equipment and note any problems for the maintenance

personnel to correct.

1. Check equipment if it is operating properly.

2. Check the cable for loose fittings or frayed cable and is seating properly on the pulleys and cams.

3. Make sure that the proper weight stack selector pin is with each machine and that the pin functions prop-

erly.

4. If something appears loose be sure to have it tightened immediately.

5. If a piece of equipment appears damaged or not operation properly, place the piece out-of-service imme-

diately.

Maintenance

7CG-5519 CalGym - Ab Crunch #150

CG-5519 Parts List

REV1

Item No. Description Rev. Part No. Qty. Item No. Description Part No. Qty.

1ADJUSTABLESEATTUBE 0UP6092 1 34 HEXHEADCAPSCREWGR‐5B/O3/8‐16X1 BNH0275 2

2ABDOMINALCRUNCHCABLE 0UP6094 1 35 HEXHEADCAPSCREWGR‐5B/O3/8‐16X11/4BNH0273 2

3BACKPAD 0UP6093 1 36 HEXHEADCAPSCREWGR‐5B/O3/8‐16X13/4 BNH0274 3

4FOAMROLL1X4X

0 UP5927 2 37 HEXHEADCAPSCREWGR‐5B/O3/8‐16X21/2 BNH0276 2

5FOOTROLLTUBE1X181/2 0 UP2944 1 38 HEXKEYLONGARMALLOY1/8ʺBNH0767 1

6FOOTROLLTUBE1X181/2(2XNUTS) 0 UP5953 139 HEXHEADCAPSCREWGR‐5B/O3/8‐16X3 BNH0282 2

7FRONTFRAME 0UP6095 1 40 HEXHEADCAPSCREWGR‐5B/O3/8‐16X5 BNH0320 4

8GUIDEROD3/4RDX481/4 0 UP5261 2 41 HEXKEYLONGARMALLOY3/16ʺ BNH0371 1

9MAINFRAME 0UP6096 1 42 NYLONBALLW/THREADEDSOCKET13/4X5/16 BNH0022 1

10 SEATPAD 0UP6097 1 43 NYLONINSERTJAMLOCKNUT3/8‐16 BNH0365 11

11 SELECTORPINW/COIL3/8X4GOLDKNOB 0 UP3035 1 44 NYLONINSERTLOCKNUTB/O5/16‐18 BNH0215 1

12 WEIGHTSHIELDSUPPORTBRACKET 0 UP5268 2 45 NYLONPULLEY3/8X1X41/2BLACK BNH0506 1

13 WEIGHTSTACKFRAME 1UP6098 1 46 PLASTICFOOTROLLHOLDER BNH1807 4

14 BNH1650 14 47 PLASTICINSERTCAP1ʺRD10‐12GA BNH0002 2

15 BNH1097 1 48 PLASTICINSERTELLIPTICALGUIDE BNH1760 1

16 BNH0235 1 49 PLASTICSHROUDLID BNH2097 1

17 BNH0553 2 50 PULLPIN1/2X31/2LIGHTSPRING(YELLOWKNOB) BNH0603 1

18 BNH2193 1 51 REARPLASTICWEIGHTSHIELDBNH2133 1

19 BNH2194 2 52 RUBBERDONUT3/4X21/2 BNH0068 2

20 BNH2149 153 RUBBERFOOTFOR6X41/4PLATE BNH1647 4

21 BNH2201 1 54 RUBBERGRIP1IDX.125X71/2 BNH0965 2

22 BNH0126 1 55 RUBBERGROMMET3/4ʺID BNH0401 2

23 BNH2224 1 56 SHOULDERBOLTALLOY3/8X3/4BNH0718 1

24 BNH1893 1 57 SOCKETSETSCREWALLOY1/4‐20X1/4 BNH0790 2

25 BNH1894 258 SOCKETSETSCREWALLOY3/8‐16X3/4 BNH0476 1

26 BNH2226 1 59 SPLITHEXTAPBOLTGR‐5B/O1/2‐13X31/2(RNDCUT) BNH1814 1

27 BNH2225 1 60 SPLITLOCKWASHERB/O1/2ʺBNH0653 1

28 BNH0201 161 SPLITLOCKWASHERB/O3/8ʺBNH0658 2

29 BNH1717 6 62 STRAPBRACKET20#SF20STAINLESSSTEEL BNH0562 1

30 BNH0233 10 63 SUPERLUBETEFLONLUBRICANT82340 BNH0704 2

31 BNH0239 20 64 U‐STYLETAPPEDHOLENUT1/4‐20 BNH0708 10

32 BNH2132 1 65 U‐SHAPEWASHER3/8IDX11/2ODX3/16THICK BNH2245 2

33 BNH0890 10 66 SNAPLINKZ/P8MMX80MM BNH0065 1

DECAL‐IMPORTANTFORBESTPERFORMANCE...(REV0)

CG-5519

Parts List

10LBSTEELWEIGHTPLATEBLACK

10LBTOPPLATEW/ADJ.SLTRBAR14WTS(EA)

ABDOMINALCRUNCHHARNESS

BLACKNYLONPULLEY3/8X1X31/2

DECALCALGYM3/CDOMED15/16X125/8

DECALWARRANTYFULLCOMMERCIAL6X1.6

DECALCALGYM2/CONCHROME111/16X71/2

DECALWEIGHTNUMBERS11/16Ø1‐20CALGYM

DECAL‐CAUTIONWEIGHTTRAININGSAFETY...(REV1)

DECAL‐EXERCISEABCRUNCH

DECAL‐IMPORTANTADJUSTCABLEHERE

DECAL‐MAINTENANANCE

DECAL‐WEIGHTSHIELDNUMBERS9X26(150LB)

FINISHEDHEXNUTB/O1/2‐13

FLATWASHER3/8IDX11/2ODX3/16THICK

FLATWASHERSAEB/O1/4ʺ

FLATWASHERSAEB/O3/8ʺ

FRONTPLASTICWEIGHTSHIELD

HEXHEADCAPSCREWGR‐5B/O1/4‐20X3/4

COLOR CHART

GRAY= SUB-ASSEMBLY PARTS

BLACK= HARDWARE