TFP313

Page 3 of 4

Design

Criteria

The following general guidelines pro-

vided for the TYCO Model ESFR-22

Pendent Sprinklers can be used for a

quick reference.

The National Fire Protection Associa-

tion (NFPA) and FM Global (FM Approv-

als) provide installation standards that

must be used to properly design an

automatic sprinkler system utilizing

Early Suppression, Fast Response

(ESFR) Sprinklers. The guidelines pro-

vided by NFPA and FM Approvals may

differ. Consequently, the appropri-

ate standard must be used for a given

installation.

In all cases, the appropriate NFPA or

FM Approvals installation standard

must be referenced to ensure applica-

bility and to obtain complete installa-

tion guidelines. The following general

guidelines are not intended to provide

complete installation criteria.

In addition to this technical data sheet,

the following Technical Data Sheets

describe other TYCO ESFR Sprinklers:

• TFP312 – Model ESFR-25 (TY9226)

K=25.2 Pendent Sprinkler

• TFP315 – Model ESFR-17 (TY7226)

K=16.8 Pendent Sprinkler

• TFP316 – Model ESFR-17 (TY7126)

K=16.8 Upright Sprinkler

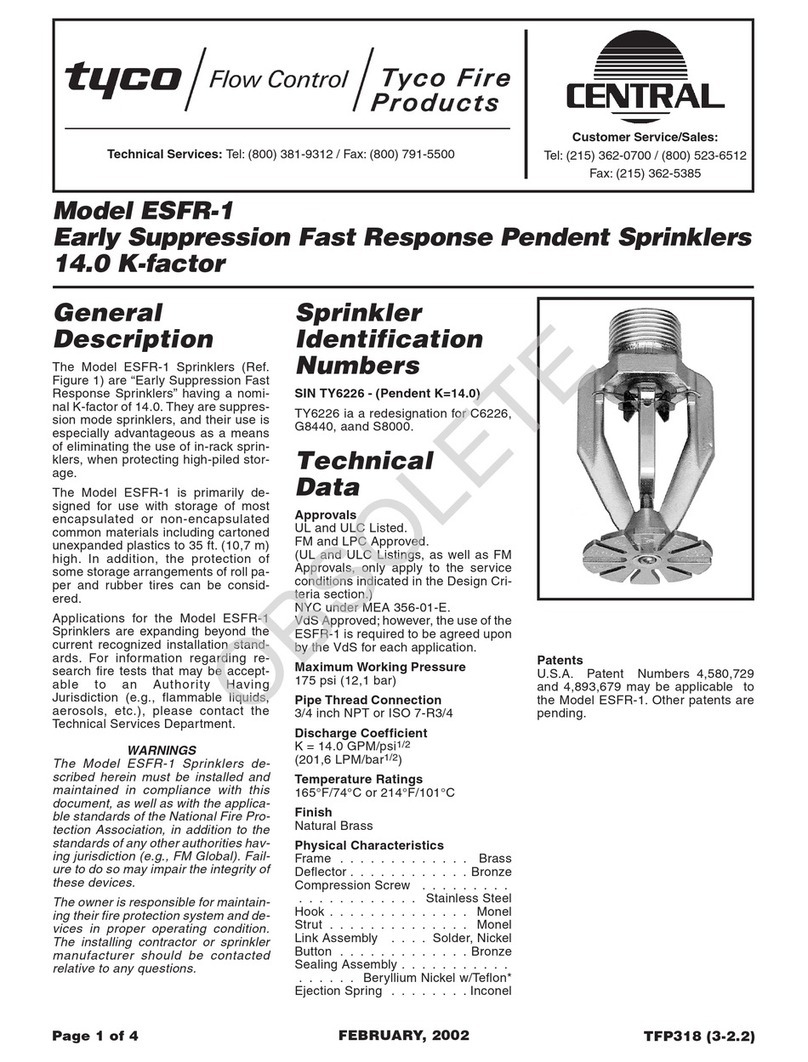

• TFP318 – Model ESFR-1 (TY6226)

K=14.0 Pendent Sprinkler

System Type

Wet pipe

Roof Construction

Unobstructed or obstructed construc-

tion (e.g., smooth ceiling, bar joists,

beam and girder, etc.). Where the

depths of the solid structural members

(e.g., beams and stem) exceed 12

inches (302 mm), install ESFR Sprin-

klers in each channel formed by the

structural members.

Ceiling Slope

Maximum 2 inch rise for 12 inch run

(16.7%)

Maximum Coverage Area

100 ft2(9,3 m2)

In some cases, the installation stan-

dards permit a greater coverage area.

Minimum Coverage Area

64 ft2(5,8 m2) per NFPA 13 / FM Global

2-0

Maximum Spacing

• 12 feet (3,7 m) for building heights up

to 30 feet (9,1 m)

• 10 feet (3,1 m) for building heights

greater than 30 feet (9,1 m); in some

cases, installation standards permit

a greater spacing

Minimum Spacing

8 feet (2,4 m)

Minimum Clearance to Commodity

36 inches (914 mm)

Deflector-to-Ceiling Distance

NFPA – 6 to 18 inches (152 to 457 mm)

Centerline of Thermal Sensing

Element-to-Ceiling Distance

FM Global – See FM Global 2-0 for

Storage Sprinklers

Operation

The fusible link assembly is com-

prised of two link halves that are joined

together by a thin layer of solder. When

the rated temperature is reached, the

solder melts and the two link halves

separate, activating the sprinkler and

flowing water.

Installation

TYCO Model ESFR-22 Pendent Sprin-

klers must be installed in accordance

with this section.

General Instructions

Damage to the fusible Link Assem-

bly during installation can be avoided

by handling the sprinkler by the frame

arms only (i.e., do not apply pressure

to the fusible Link Assembly), and by

using the appropriate sprinkler wrench.

Failure to do so can lead to an unstable

link assembly and premature activation

of the sprinkler. Damaged sprinklers

must be replaced.

A leak-tight 1 inch NPT sprinkler joint

should be obtained by applying a min-

imum-to-maximum torque of 20 to 30

ft.-lbs. (26,8 to 40,2 Nm). Higher levels

of torque can distort the sprinkler inlet

with consequent leakage or impairment

of the sprinkler.

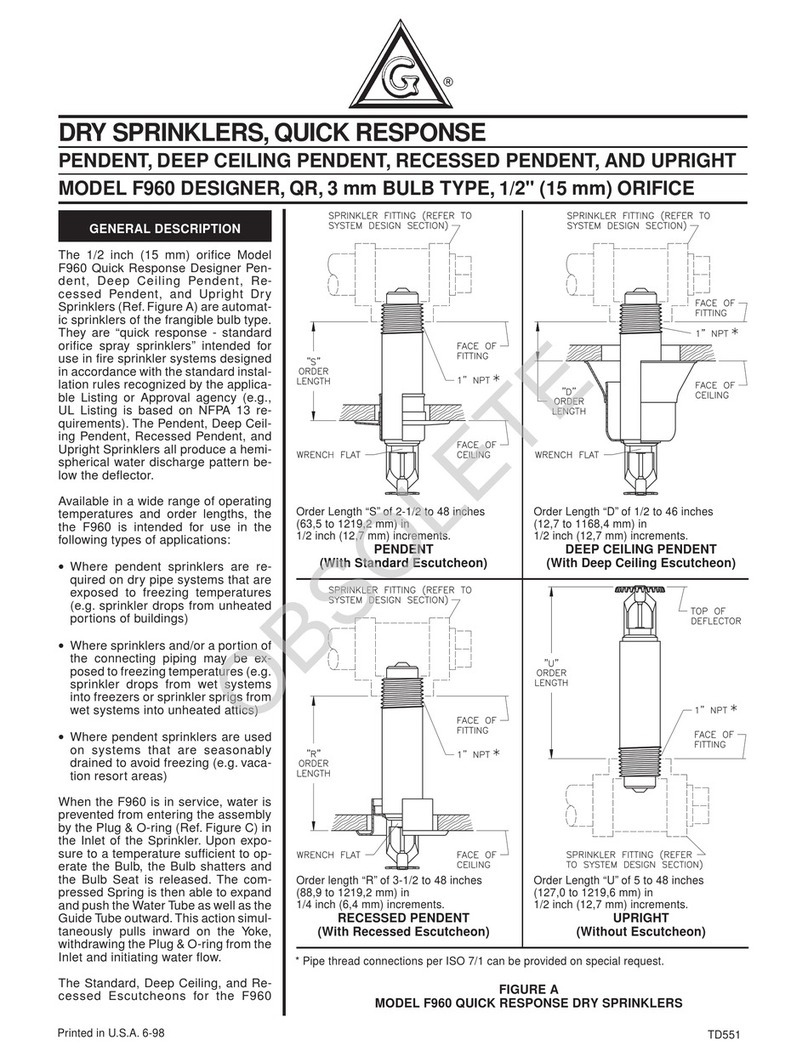

Note: Install the Model ESFR-22 Pendent

Sprinkler in the pendent position (Ref.

Figure 2).

Step 1. With pipe-thread sealant

applied, hand-tighten the sprinkler into

the sprinkler fitting. Do not apply pres-

sure to the Link Assembly, and handle

the Model ESFR-22 Pendent Sprinkler

only by the Frame arms.

Step 2. Use only the W-Type 32 Sprin-

kler Wrench (Ref. Figure 2) to install

the Model ESFR-22 Pendent Sprinkler.

Fully engage (seat) the wrench recess

on the sprinkler wrench flats (Ref.

Figure 1) and wrench-tighten.

Step 3. After installation, remove

the Protective Sprinkler Cap and

inspect the Link Assembly of each

Model ESFR-22 Pendent Sprinkler for

damage. In particular, verify that the

Link Assembly and Hook are positioned

as illustrated in Figure 1, and that the

Link Assembly is not bent, creased,

or forced out of normal position in any

way. Replace damaged sprinklers.

WRENCH

FLATS

SPRINKLER

CAP

APPLY WRENCH

RECESS TO ESFR-22

FIGURE 2

W-TYPE 32

SPRINKLER WRENCH