©1998 Central Sprinkler Company

Printed in U.S.A. ELO-16 GB FR OH.1

Ordering

Information

Ordering Information: When placing an

order, indicate the full product name.

Please specify the quantity, model, style,

orifice size, temperature rating, type of

finish or coating, and sprinkler wrench.

Availability and Service: Central

sprinklers, valves, accessories, and

other products are available throughout

the U.S. and Canada, and internation-

ally, through a network of Central

Sprinkler distribution centers. You may

write directly to Central Sprinkler Com-

pany, or call (215) 362-0700 for the

distributor nearest you.

Guarantee: Central Sprinkler Company

will repair and/or replace any products

found to be defective in material or

workmanship within a period of one year

from the date of shipment. Please refer

to the current Price List for further details

of the warranty.

Patents: The ELO-16 GB FR Optima™

sprinklers are protected under U.S.

Patent No. 5,366,022.

Conversion Table:

1 inch = 25.400 mm

1 foot = 0.3048 m

1 pound = 0.4536 kg

1 foot pound = 1.36 Nm

1 psi = 6.895 kpa

= 0.0689 bar

= 0.0703 kg/cm2

1 U.S. gallon = 3.785 dm3

= 3.785 liters

Conversions are approximate.

OPTIMA™ is a registered trademark of

Central Sprinkler Company.

Sprinklers must be handled care-

fully. They must not be transported or

stored where ambient temperature

may exceed 100°F/38°C. For best

results, store them in a dry, cool

location in the original shipping

package.

Do not install sprinklers that have

been dropped or visibly damaged.

Sprinklers should never be painted,

coated, plated, or altered in any other

way from manufactured condition or

they may not function properly. Any

sprinklers altered in such manner

must be replaced.

The owner is responsible for the

proper operating condition of all fire

protection devices and accessories.

The NFPA Standard 25 entitled,

“Inspection, Testing and Maintenance

of Water-Based Fire Protection

System”

, contains guidelines and

minimum maintenance requirements.

Furthermore, the local

Authority

Having Jurisdiction

may have addi-

tional regulations and requirements

for maintenance, testing, and inspec-

tion that must be obeyed.

It is advisable to have sprinkler

systems inspected regularly by a

qualified inspection service. Length

of time between such inspections can

vary due to accessibility, ambient

atmosphere, water supply, and site

activity.

Do not attempt to reassembly or

otherwise reuse a sprinkler that has

operated. Replace any sprinkler

exhibiting corrosion or damage;

always use new sprinklers of the

same type and temperature rating as

replacements.

Because the discharge pattern is

critical to protection of life and

property, nothing should be hung or

attached to the sprinkler unit that

would disrupt the pattern. Such

obstructions must be removed. In the

event that construction has altered

the original configuration, additional

sprinklers should be installed to

maintain the protection level.

Do not attempt to replace sprinklers

without first removing the fire protec-

tion system from service. Be certain

to secure permission from all

Authori-

ties Having Jurisdiction

, and notify all

personnel who may be affected

during system shutdown. A fire

watch during maintenance periods is

a wise precaution.

To remove the system from service

mode, first refer to the system

operating guide and valve instruction.

Drain the water and relieve pressure

in the pipes. Remove the existing

unit and install the replacement, using

only the special sprinkler wrench. Be

certain to match the model, style,

orifice, and temperature rating.

A fire protection system that has

been shut off after an activation

should be returned to service immedi-

Installation Sequence

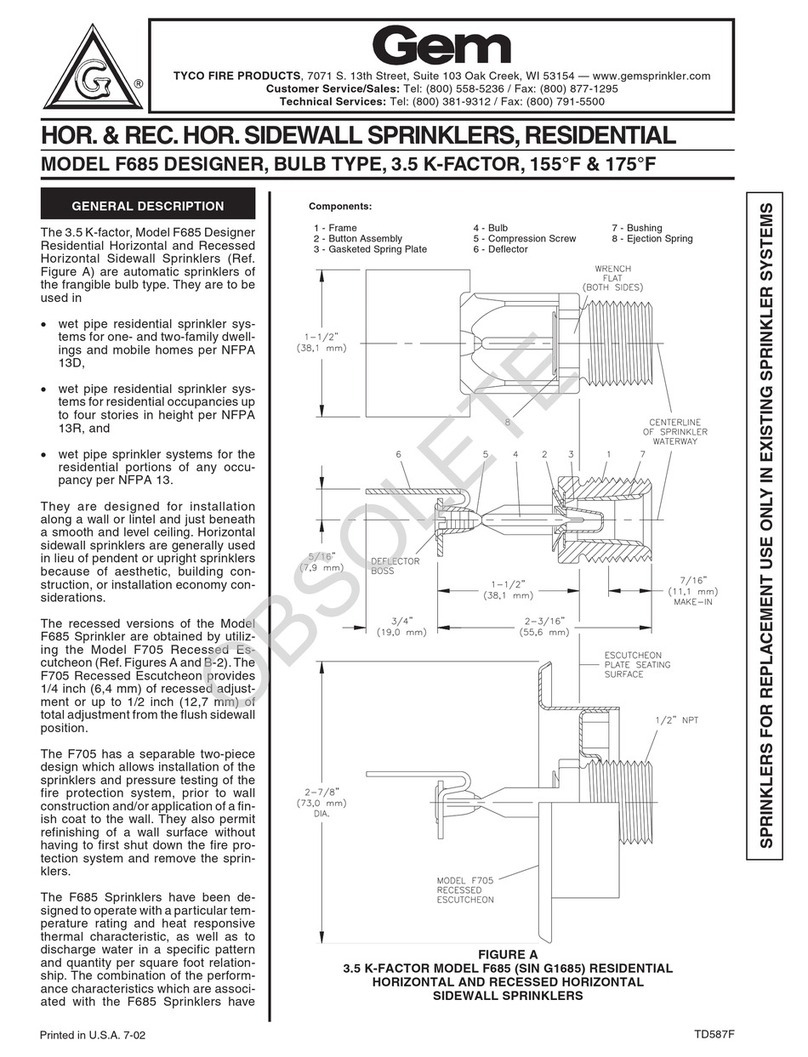

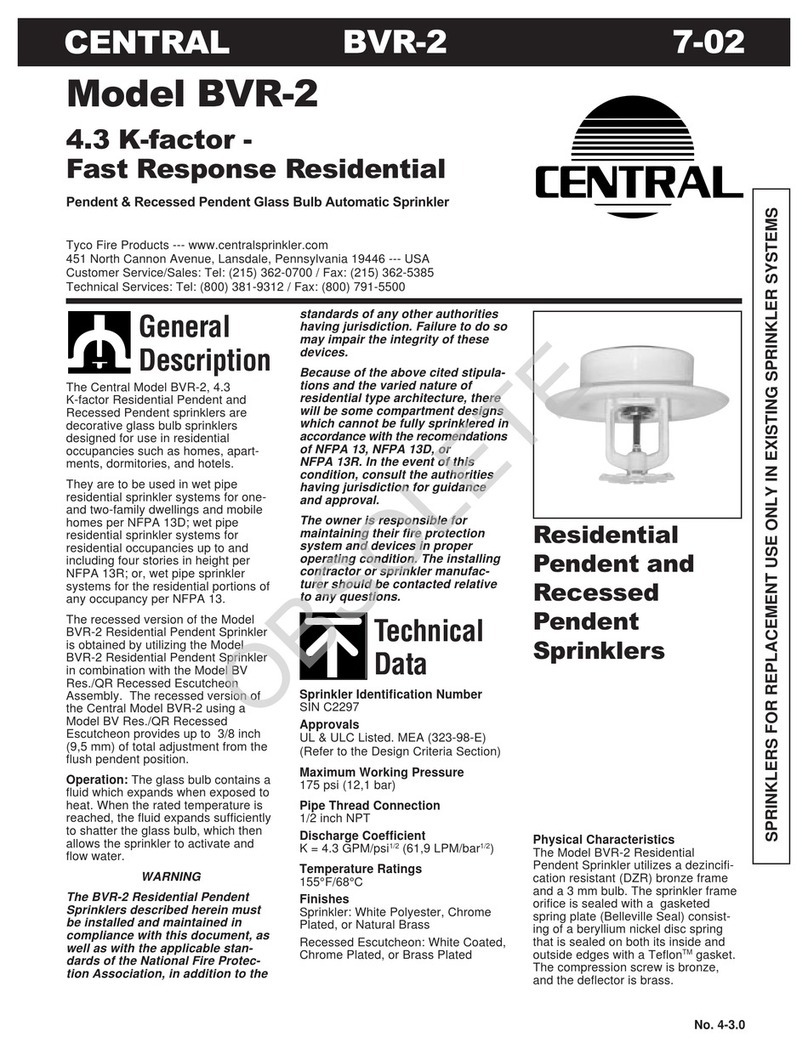

Step 1. For Recessed Pendent

Sprinklers, the face of the sprinkler

fitting should be installed a nominal 3⁄4"

(±3⁄8")/ 19.1mm (±9.5mm) behind the

ceiling line. Adjustments are made via

the push-on escutcheon.

Step 2. Use only a non-hardening

pipe joint compound or Teflon* tape.

Apply only to the male threads.

Step 3. Hand tighten the sprinkler into

the fitting. Use the appropriate Central

wrench to tighten the unit into the

fitting. A leak-tight joint requires only 7

to 14 ft.-lbs.( 9.5 to 19.0 Nm) of torque;

a tangential force of 14 to 28 lbs. (62.3

to 124.5 N) delivered through a 6" (150

mm) handle will deliver adequate

torque. Torque levels over 21 ft.-lbs.

(28.6 Nm) may distort the orifice seal,

resulting in leakage.

The upright sprinklers shall be

oriented so the frame arms are parallel

with the branch line pipe per NFPA.

ately. Inspect the entire system for

damage and replace or repair as

necessary. Sprinklers that did not

operate but were subjected to corro-

sive elements of combustion or

excessive temperatures should be

inspected, and replaced if need be.

The

Authority Having Jurisdiction

will

detail minimum replacement require-

ments and regulations.

*Teflon is a trademark of the DuPont Corp.

Care &

Maintenance

Central Sprinkler Company

451 North Cannon Avenue, Lansdale, PA 19446

PHONE (215) 362-0700

FAX (215) 362-5385