falls away to expose the Sprinkler

Assembly. At this point the Deflector

supported by the Arms drops down to its

operational position.

The glass bulb contains a fluid which

expands when exposed to heat. When the

rated temperature is reached, the fluid

expands sufficiently to shatter the glass

bulb, which then allows the sprinkler to

activate & flow water.

WARNING

The Model BV4 & BV4-FR Concealed

Pendent Sprinklers described herein must

be installed & maintained in compliance

with this document, as well as with the

applicable standards of the National Fire

Protection Association, in addition to the

standards of any other authorities having

jurisdiction. Failure to do so may impair the

integrity of these devices.

The owner is responsible for maintaining

their fire protection system and devices in

proper operating condition. The installing

contractor or sprinkler manufacturer

should be contacted relative to any

questions.

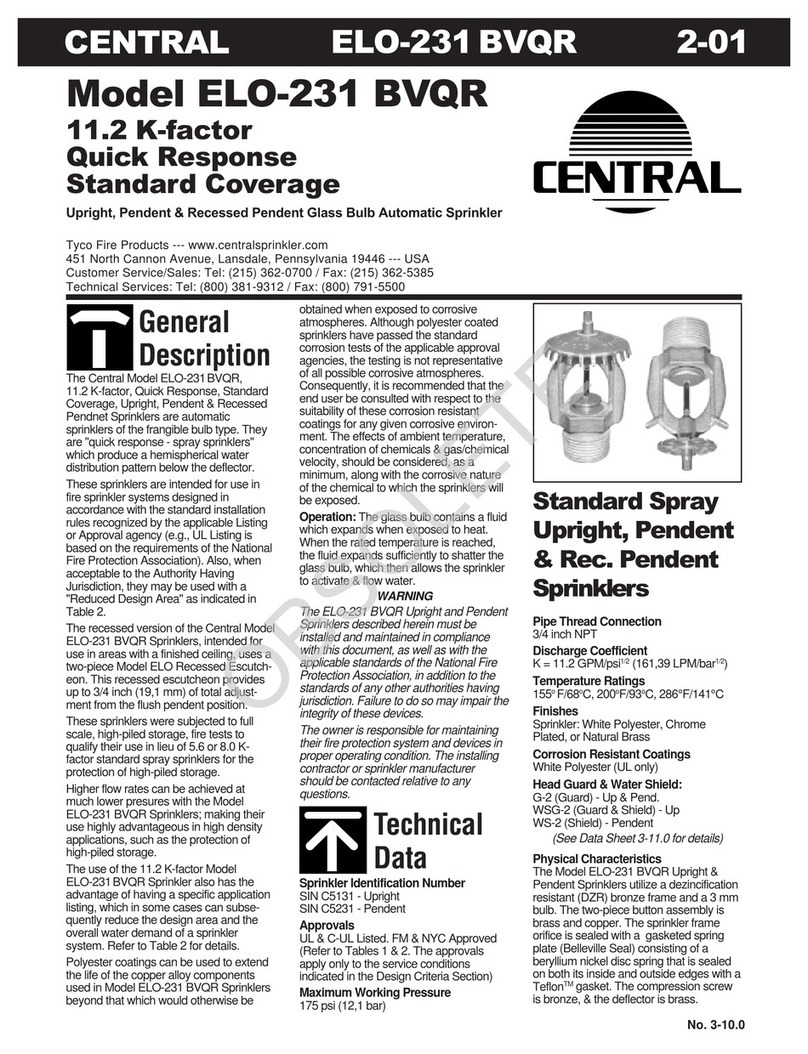

Sprinkler Identification Number

SIN C3551 - Model BV4

SIN C3531 - Model BV4-FR

Approvals

UL and C-UL Listed. NYC and

FM Approved.

(The approvals apply only to the service

conditions indicated in the Design Criteria

Section)

Maximum Working Pressure

175 psi (12,1 bar)

Pipe Thread Connection

1/2 inch NPT

Discharge Coefficient

K = 5.6 GPM/psi1/2 (80,6 LPM/bar1/2)

Tyco Fire Products --- www.centralsprinkler.com

451 North Cannon Avenue, Lansdale, Pennsylvania 19446 --- USA

Customer Service/Sales: Tel: (215) 362-0700 / Fax: (215) 362-5385

Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500

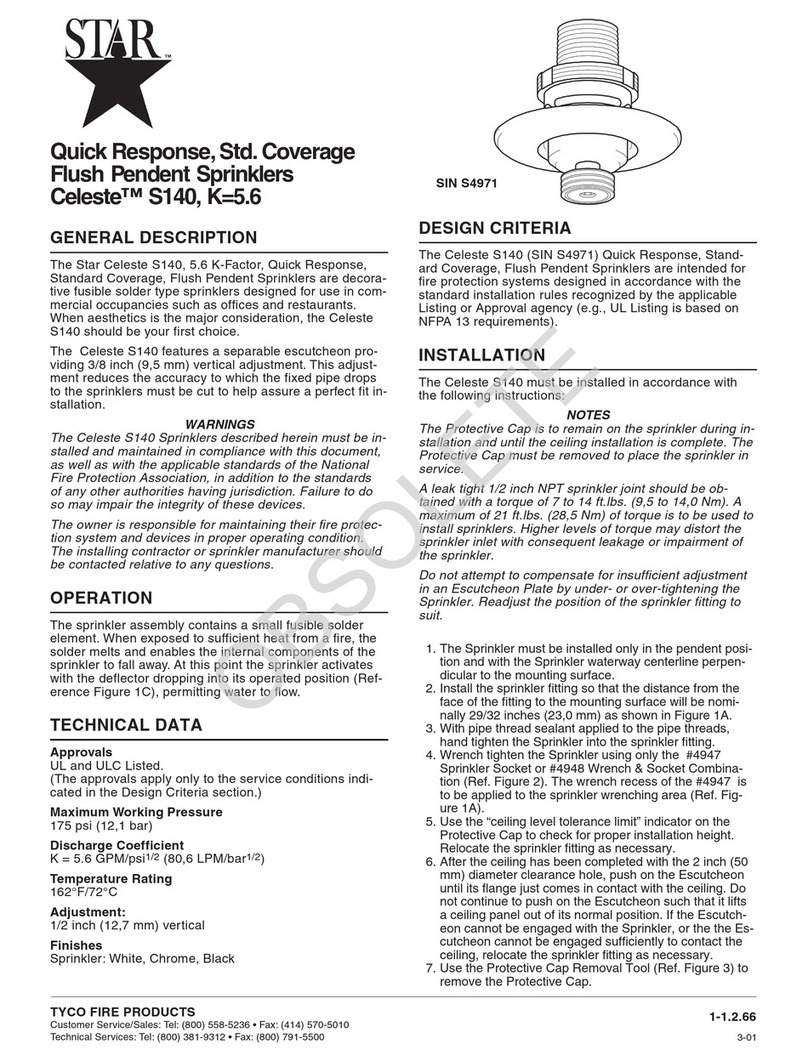

Model BV4 & BV4-FR

5.6 K-factor

Standard & Quick Response

Standard Coverage

Concealed Pendent Glass Bulb Automatic Sprinkler

No. 1-8.0

General

Description

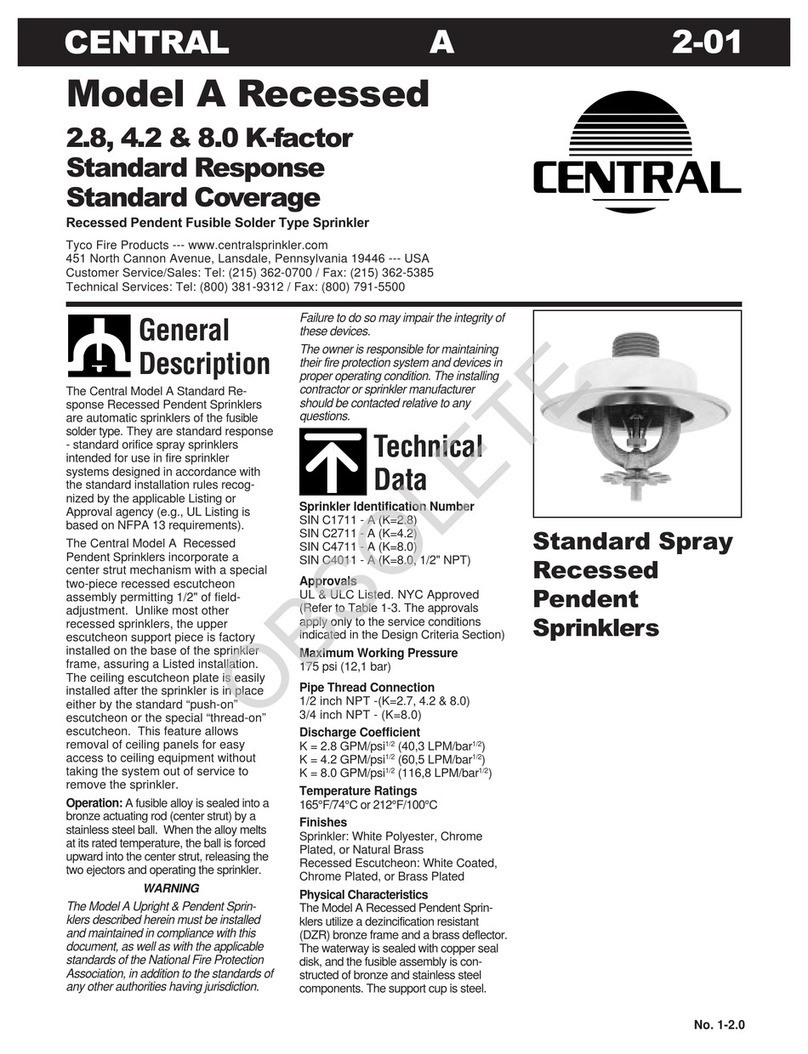

The Central Model BV4, 5.6 K-factor,

standard response & BV4-FR, 5.6

K-factor, quick response - standard

coverage, decorative glass bulb type

spray sprinklers designed for use in light or

ordinary hazard, commercial occupancies

such as banks, hotels, shopping malls,

etc.

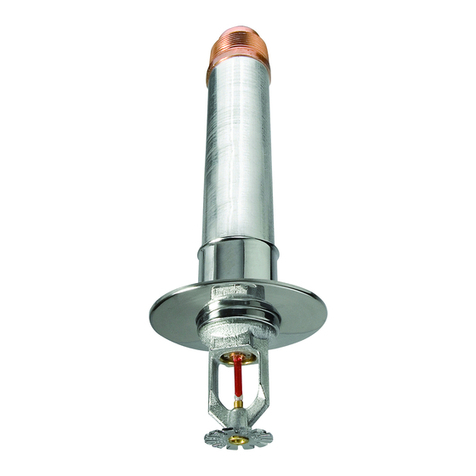

Each unit includes a Cover Plate Assem-

bly which conceals the sprinkler operating

components above the ceiling. The

separable two-piece design of the Cover

Plate and Support Cup Assemblies allows

installation of the sprinklers and pressure

testing of the fire protection system prior to

installation of a suspended ceiling or

application of the finish coating to a fixed

ceiling. They also permit removal of

suspended ceiling panels for access to

building service equipment without having

to first shut down the fire protection system

and remove sprinklers.

Also, the separable two-piece design of

the sprinkler provides for 1/2 inch

(12,7 mm) of vertical adjustment, to

reduce the accuracy to which the length of

fixed pipe drops to the sprinkler must be

cut.

The BV4 & BV4-FR Concealed Pendent

Sprinklers are shipped with a Disposable

Protection Cap. The Protective Cap is

temporarily removed to install the BV4 &

BV4-FR, and then replaced to protect the

BV4 & BV4-FR while the ceiling is being

installed and finished. The tip of the

Protection Cap can be used to mark the

center of the ceiling hole into plaster

board, ceiling tiles, etc. by pushing the

ceiling product against the Protection Cap.

When the ceiling installation is complete,

the Protection Cap is removed and the

Cover Plate Assembly installed.

Operation: When exposed to heat from a

fire, the Cover Plate, which is soldered to

the Retainer Assembly at three points,

Technical

Data

CENTRAL BV4 & BV4-FR 2-01

Standard Spray

Concealed

Pendent

Sprinklers

Temperature Ratings

155°F/68°C Sprinkler - 135°F/57°C Plate

200°F/93°C Sprinkler - 165°F/74°C Plate

Finishes

Sprinkler: Natural Brass

Cover Plate: Chrome or Brass Plated;

*Flat White, Bright White, or Custom

Painted

* Standard Finish supplied when White is

specified

Physical Characteristics

The Model BV4 & BV4-FR Concealed

Pendent Sprinklers utilize a dezincification

resistant (DZR) bronze frame and a 5 mm

(standard response) or 3 mm bulb (quick

response). The two-piece button assem-

bly is brass and copper. The sprinkler

frame orifice is sealed with a gasketed

spring plate (Belleville Seal) consisting of a

beryllium nickel disc spring that is sealed

on both its inside and outside edges with a

TeflonTM gasket. The arms and deflector

are bronze, and the support cup is steel.

The cover plate and retainer assembly are

brass.