into the system piping, as well as

through the Alarm Port to actuate the

system alarms.

As water flows into the system, the

Model FSV-1 Fail-Safe Valve (Item 5 -

Fig. 2A, also described in Technical

Data Sheet TFP1386) becomes pres-

surized and upon operation constantly

vents the DV-5 Diaphragm Chamber

so as to maintain the DV-5 Valve in the

open (operated) position until the sys-

tem is reset.

WARNING

The Model DV-5 Double Interlock Pre-

action System with Electric/Pneumatic

Actuation described herein must be

installed and maintained in compli-

ance with this document, as well as

with the applicable standards of the

National Fire Protection Association,

in addition to the standards of any

other authorities having jurisdiction.

Failure to do so may impair the per-

formance of the related devices.

The owner is responsible for maintain-

ing their fire protection system and de-

vices in proper operating condition.

The installing contractor or manufac-

turer should be contacted with any

questions.

Technical

Data

Approvals

UL and C-UL Listed. FM Approved.

Deluge Valve

Model DV-5.

Riser Check Valve

Model CV-1FR.

NOTE

1-1/2 inch (DN40) risers utilize a 2 inch

(DN50) Riser Check Valve in combina-

tion with the 1-1/2 inch (DN40) Model

DV-5 Deluge Valve.

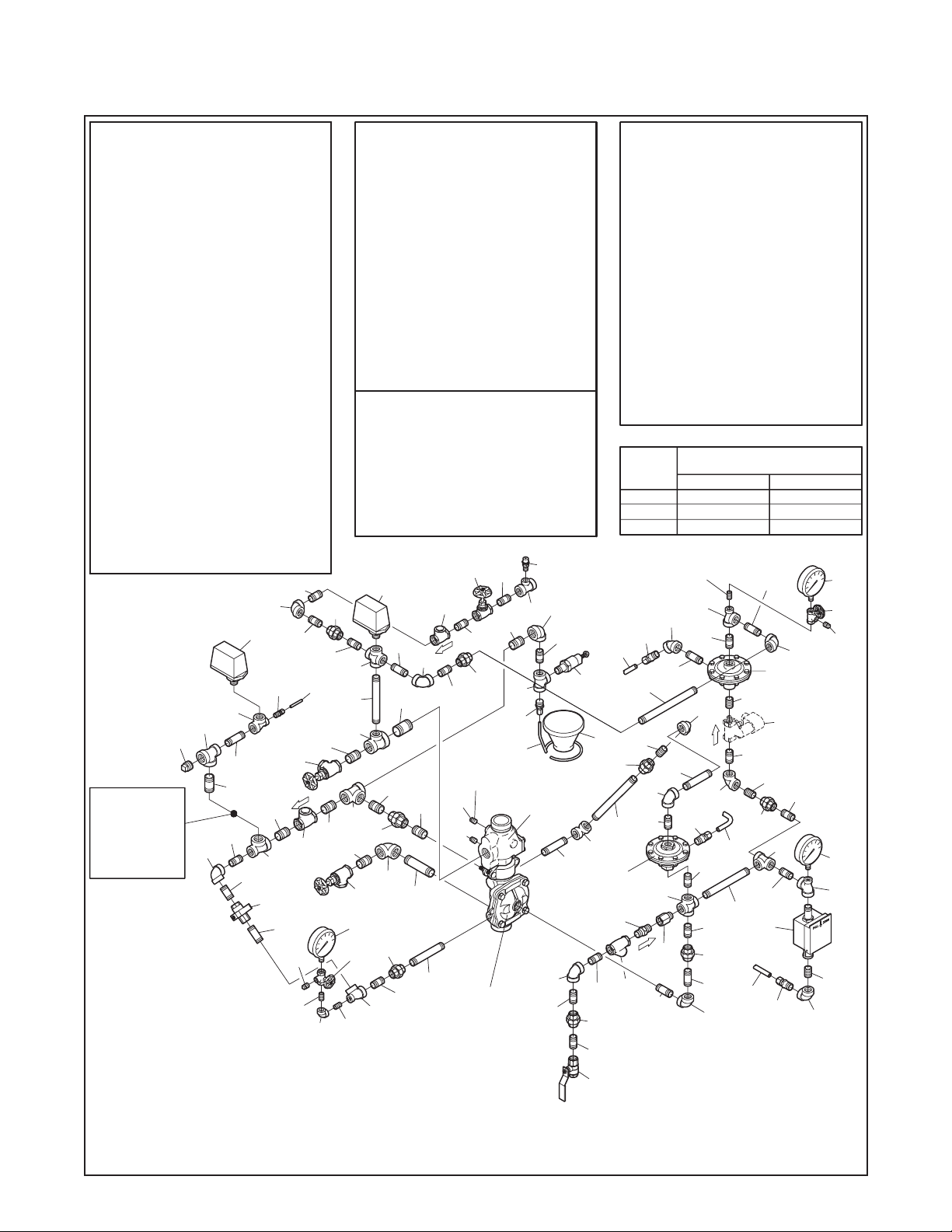

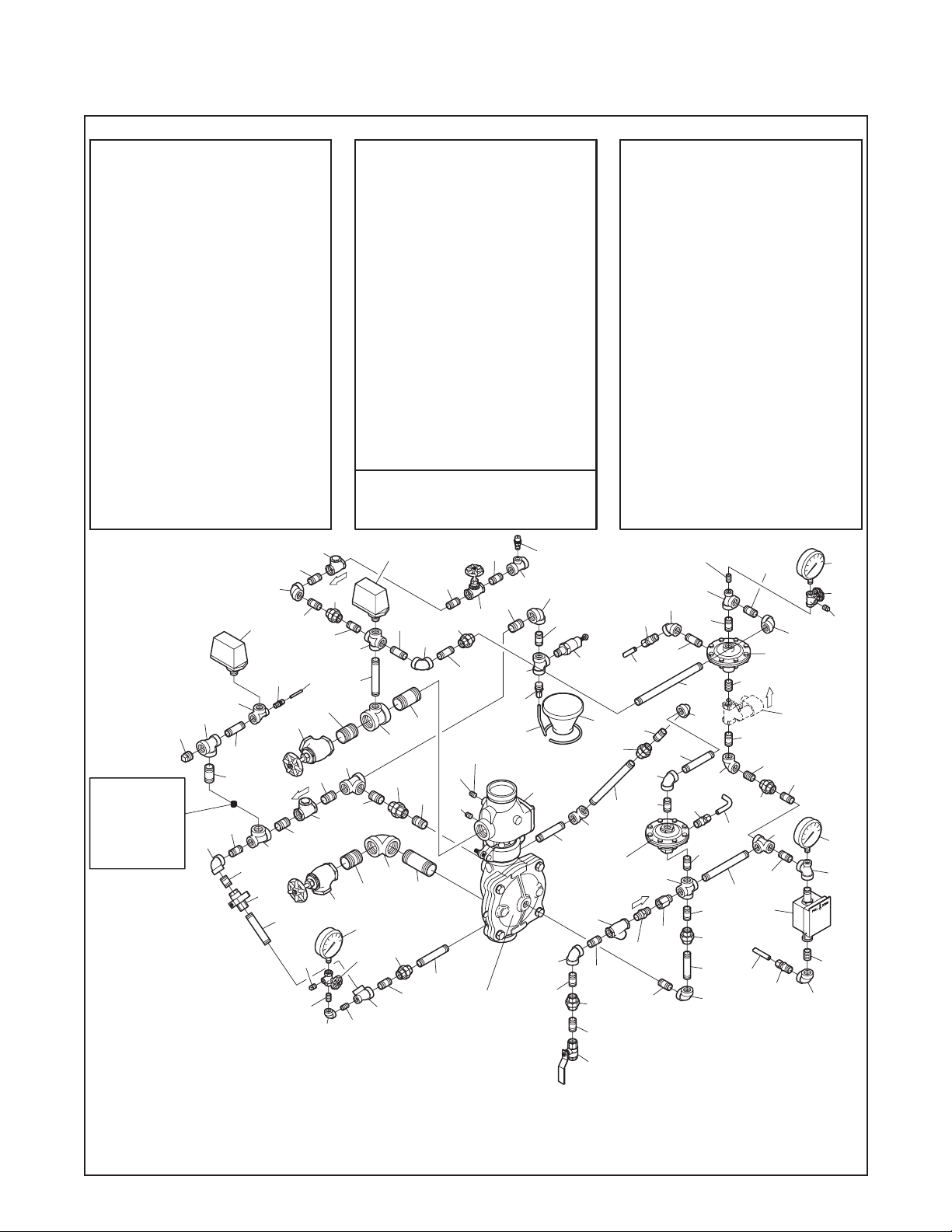

Valve Trim

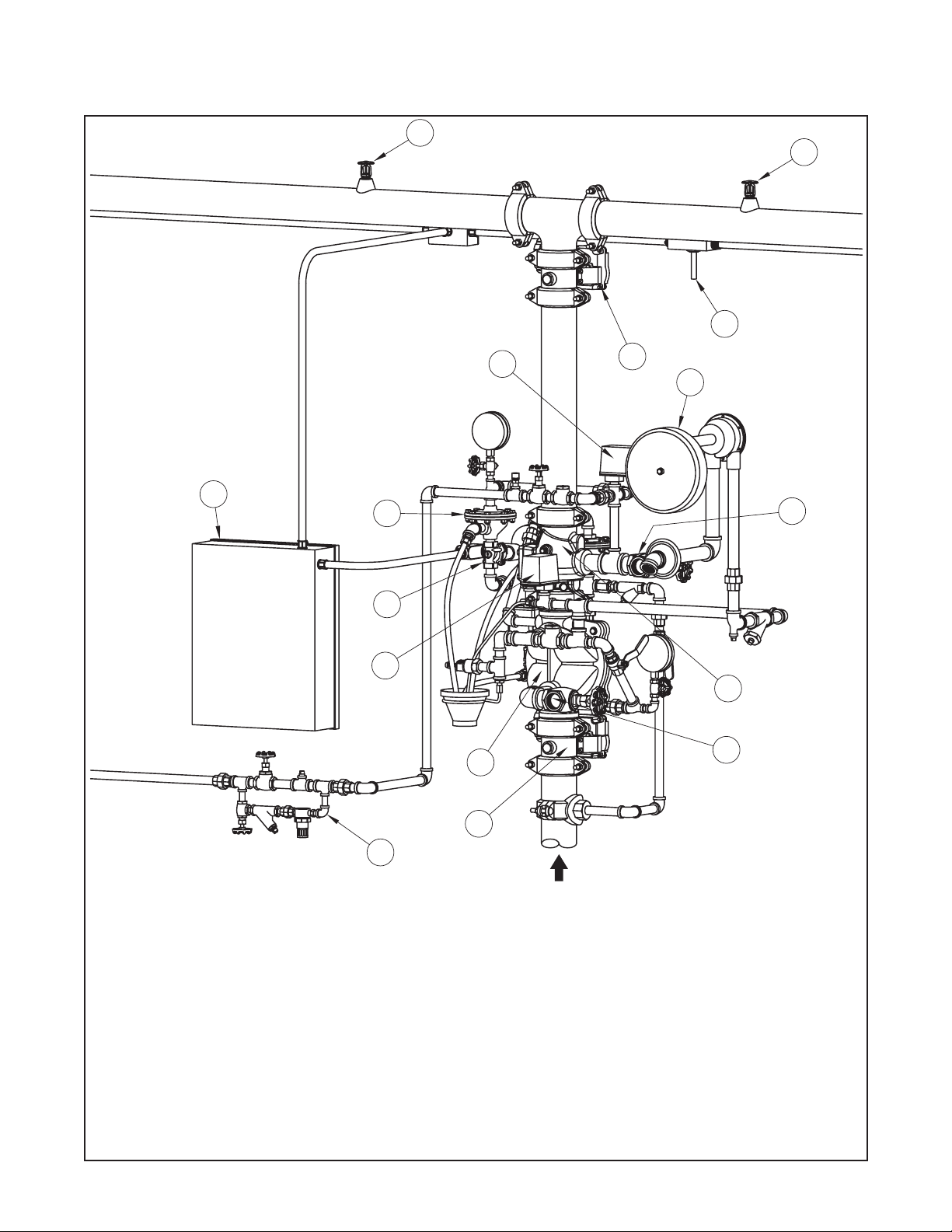

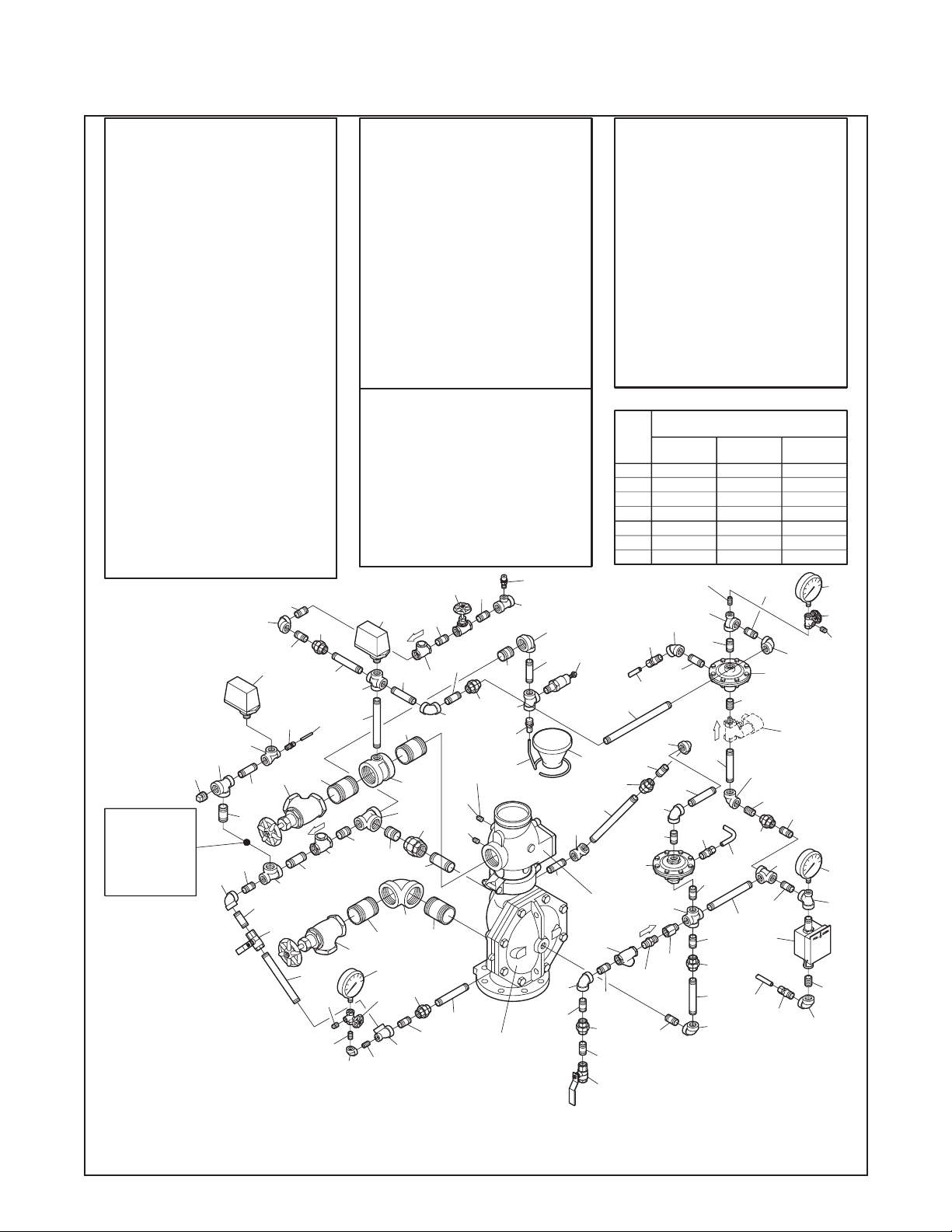

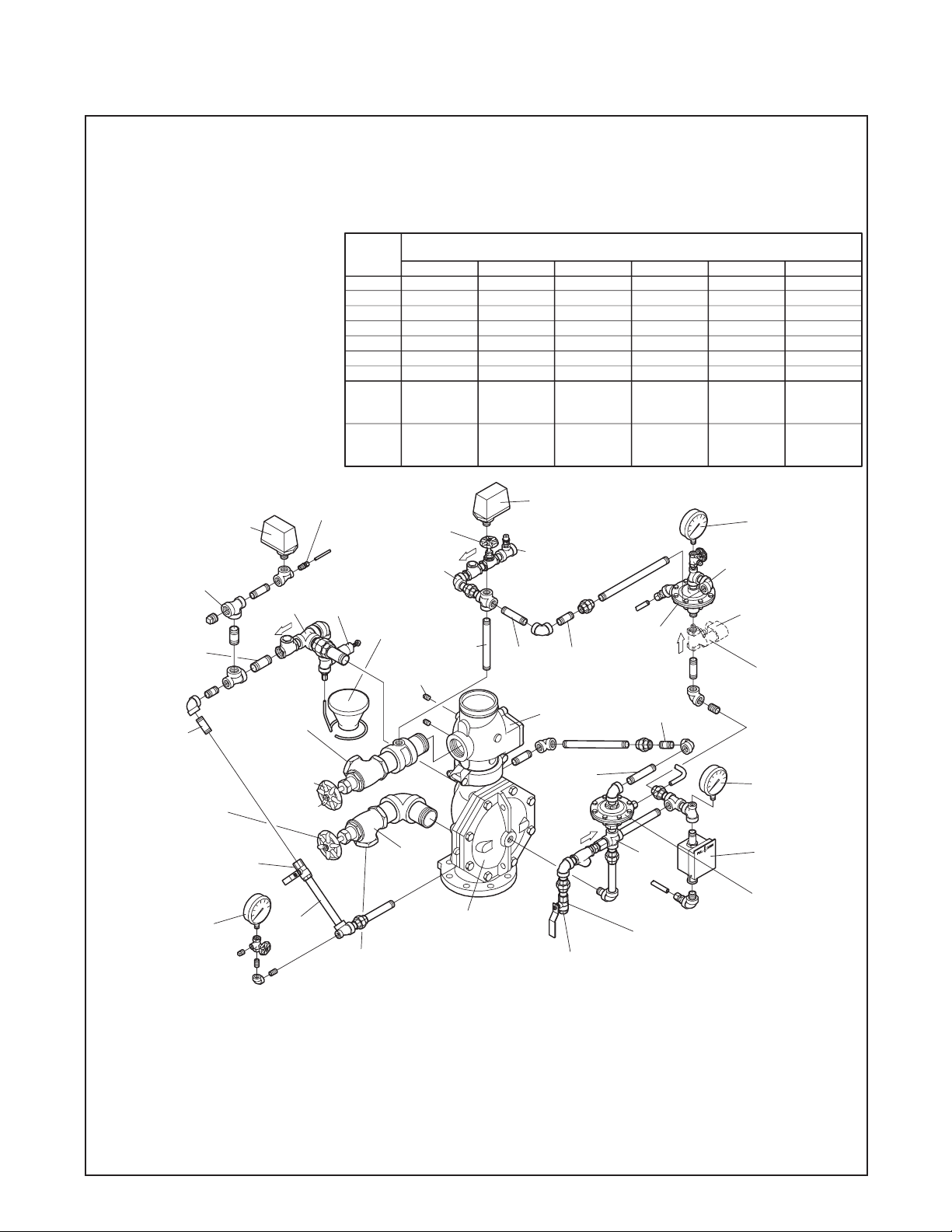

The Double Interlock Preaction Sys-

tem with Electric/Pneumatic Actuation

Trim (Fig. 2A/2B) forms a part of the

laboratory listings and approvals. The

trim is necessary for proper operation

of the DV-5 Valve.

Each package of trim includes the fol-

lowing items:

•Water Supply Pressure Gauge

•Diaphragm Chamber

Pressure Gauge

•Diaphragm Chamber Connections

•Manual Control Station

•Main Drain Valve

•System Drain Valve

•Alarm Test Valve

•Automatic Drain Valve

•System Air Pressure Gauge

•Air Supply Connections

•Low Air Pressure Alarm Switch

•Waterflow Pressure Alarm Switch

•Dry Pilot Actuator

•Pressure Operated Relief Valve

To ease field assembly of the trim ar-

rangement, the trim components are

provided partially assembled as

showninFigure2B.

The trim arrangement is provided with

galvanized or black nipples and fit-

tings. The galvanized trim is intended

for non-corrosive or corrosive condi-

tions, whereas the black trim is princi-

pally intended for use with AFFF sys-

tems.

NOTE

When the system pressure is greater

than 175 psi (12,1 bar), provision is to

be made to replace the standard order

300 psi (20,7 bar) Water Pressure

Gauges, shown in Figure 2A/2B with

separately ordered 600 psi (41,4 bar)

Water Pressure Gauges.

System Design Considerations

Because a double interlock preaction

system requires time for a drop in sys-

tem air pressure to occur (concurrently

with the response time for the separate

fire detection system) before it will al-

low water to enter the system piping,

this system has characteristics similar

to a dry pipe sprinkler system. There-

fore, the system design considerations

for a dry pipe system are normally

applied to a double interlock preaction

system — including a 30% increase in

design area; a maximum 1 minute

water delivery time for system capaci-

ties of 750 gallons (2800 litres) or

more; and, prohibition of gridded sys-

tem piping.

In order to readily perform the System

Inspection Procedure described in the

Care and Maintenance section, it is

Page 9 of 16

TFP1460

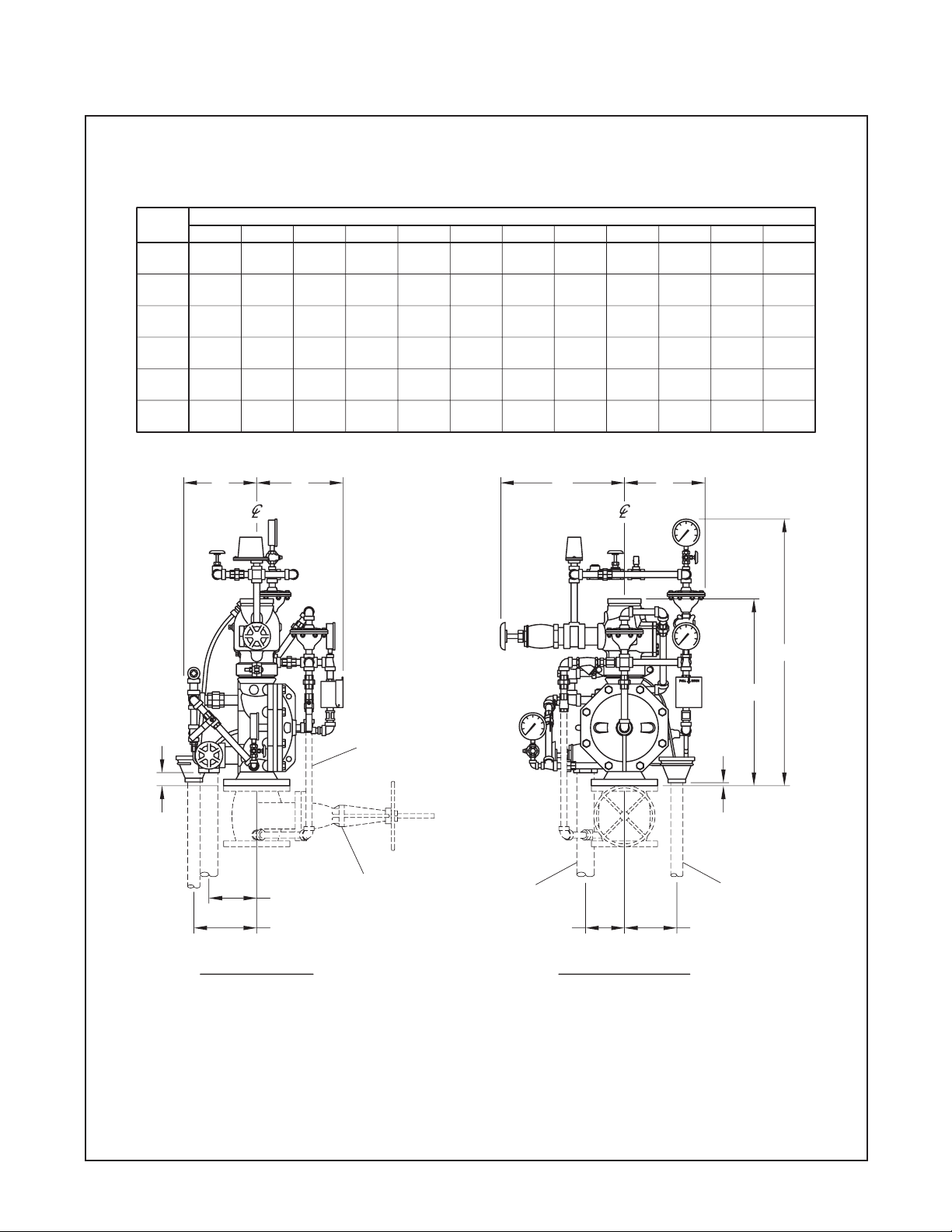

GRAPH A

DOUBLE INTERLOCK PREACTION SYSTEM

AIR PRESSURE REQUIREMENTS

WATER S

PPLY PRESS

RE IN PSI

100

RANGE OF ACTUATOR OPENING PRESSURE

MINIMUM SYSTEM AIR PRESSURE

AIR PRESSURE IN PSI

20 60

15

0

30

45

140 180 250200