Technical

Data

Approvals:

UL and C-UL Listed. FM Approved.

NYC under MEA 172-02-E (4 and 6

inch).

DryPipeValve:

The Model DPV-1 Dry Pipe Valves are

for vertical installations (flow going

up), and they are rated for use at a

maximum service pressure of 250 psi

(17,2 bar). The Valve dimensions are

shown in Figure 7.

Flanged connections are available

drilled per ANSI, ISO, AS, and JIS

specifications (Ref. Table A). The

grooved outlet connections, as appli-

cable, are cut in accordance with

standard groove specifications for

steel pipe. They are suitable for use

with grooved end pipe couplings that

are listed or approved for fire protec-

tion system service. Available combi-

nations of inlet and outlet connections

are detailed in the Ordering Procedure

section.

Threaded port connections of valves

having flanges drilled to ANSI, AS, or

JIS specifications are NPT threaded

per ANSI Standard B1.20.1. Threaded

port connections of valves having

flanges drilled to ISO are available

either threaded per ISO 7/1 or NPT

threaded per ANSI Standard B1.20.1.

Valves with NPT threaded ports will

readily accept the trim arrangements

detailed in Figures 4, 5, and 6.

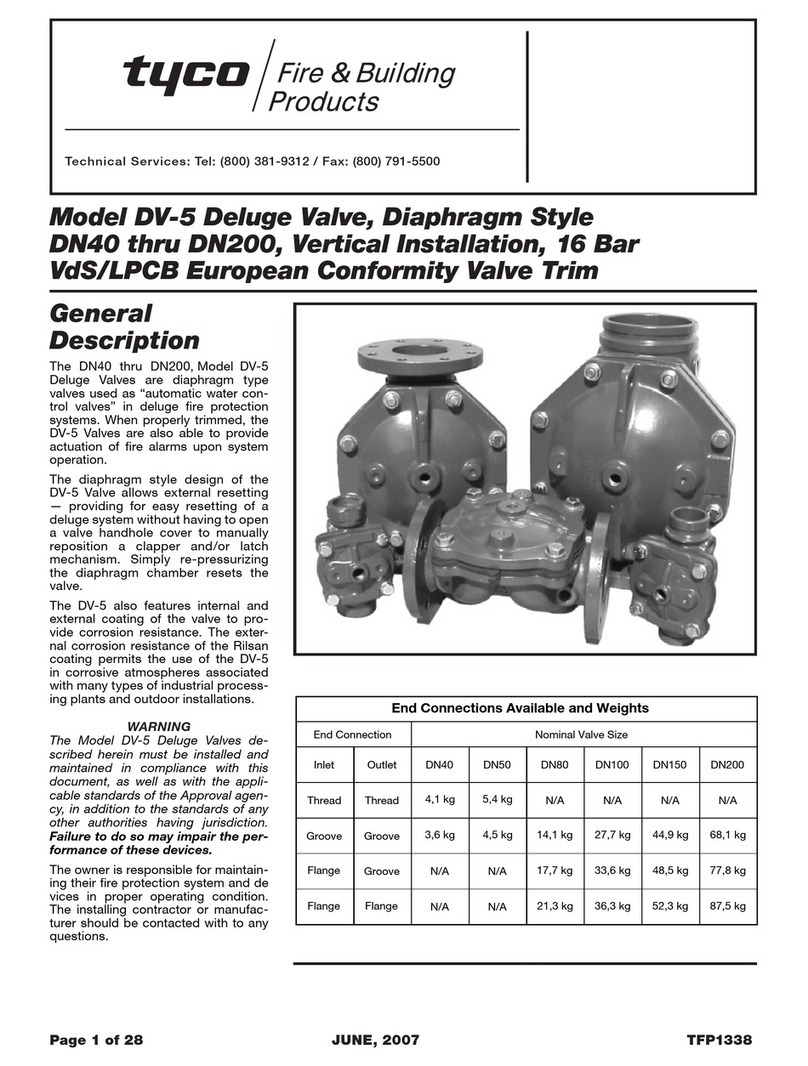

Components of the DPV-1 Valves are

shown in Figure 1. The Body and

Handhole Cover are ductile iron. The

Handhole Cover Gasket is neoprene,

and the Clapper Facing is EPDM. The

Air/Water Seat Ring is brass, the Clap-

per is bronze or aluminum bronze, and

both the Clapper Retaining Plate and

Latch are bronze. The Hinge Pin is

aluminum bronze, and the fasteners

for the Handhole Cover are carbon

steel.

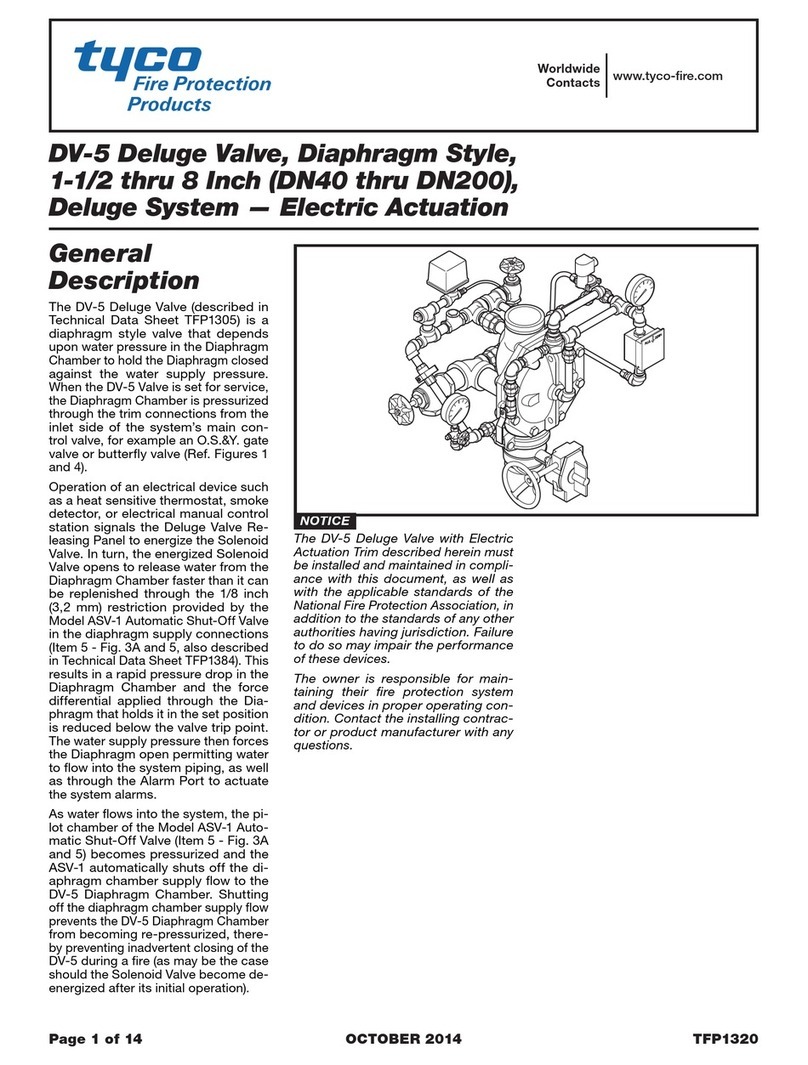

Valve Trim:

Installation dimensions are given in

Figure 7, and the Valve Trim is illus-

trated in Figures 4, 5, and6. TheValve

Trim forms a part of the laboratory

listings and approval of the DPV-1

Valve and is necessary for the proper

operation of the DPV-1 Valve. Each

package of trim includes the following

items:

•Water Supply Pressure Gauge

•System Air Pressure Gauge

•Air Supply Connections

•Main Drain Valve

•Low Body Drain Valve

•Alarm Test Valve

•Automatic Drain Valve

•Drip Funnel

•Connections For Optional Quick

Opening Device (Accelerator)

NOTE

When the system pressure is greater

than 175 psi (12,1 bar), provision is to

be made to replace the standard order

300 psi (20,7 bar) Water Pressure

gauge with a separately ordered 600

psi (41,4 bar) Water Pressure Gauge.

Air Supply:

TableBshows thesystem airpressure

requirementsas afunctionofthewater

supply pressure. The air (or nitrogen)

pressure in the sprinkler system is rec-

ommended to be automatically main-

tained by using one of the following

pressure maintenance devices, as ap-

propriate:

•Model AMD-1 Air Maintenance De-

vice (pressure reducing type).

•Model AMD-2 Air Maintenance De-

vice (compressor control type).

•Model AMD-3 Nitrogen Mainte-

nance Device (high pressure reduc-

ing type).

The Pressure Relief Valve provided

with the valve trim is factory set to

relieve at a pressure of approxi-

mately 45 psi (3,1 bar). If the normal

system air pressure is less than or

exceeds 40 psi (2,8 bar), then the

pressure Relief Valve must be reset to

relieve at a pressure that is in accord-

ance with the Authority Having Juris-

diction.

Quick Opening Device:

As an option, the Model DPV-1 Dry

Pipe Valve may be equipped with the

Model QRS Electronic Dry Pipe Valve

Accelerator (4 and 6 inch sizes) as

detailed in Technical Data Sheet

TFP1100 or the Model ACC-1 Me-

chanical Dry Pipe Valve Accelerator

(2-1/2, 3, 4, and 6 inch sizes) as de-

tailed in Technical Data Sheet

TFP1112.

TheQRSortheACC-1isusedtore-

duce the time to valve actuation fol-

lowing the operation of one or more

automatic sprinklers. In some cases

the use of a quick opening device such

astheQRSortheACC-1maybere-

quired to meet the requirements of the

National Fire Protection Association to

meet water delivery times.

Patents:

U.S.A. Patent No. 6,557,645

Page4of20 TFP1020

ANSI B16.1 AS 2129JIS B 2210

(Class 125) (Table E)(10K)

A

7.50

9.50

(190,5)

(241,3)

B

0.75

0.88

(19,0)

(22,2)

7.00

9.25

(178,0)

(235,0)

0.71

0.87

(18,0)

(22,0)

6.89

(175,0)

Flange Drilling Specification

Nominal Dimensions in Inches and (mm)

9.45

(240,0)

Valve

4 Inch

6 Inch

(DN100)

(DN150)

N

8

8

ISO 7005-2

(PN16)

7.09

9.45

(180,0)

(240,0)

ABN

8

8

ABN

8

8

ABN

8

8

Dim. Dim.

Nominal

Qty. Dim. Dim. Qty. Dim. Dim. Qty. Dim. Dim. Qty.

Same drilling as for BS 4504 Section 3.2 (PN16) and DIN 2532 (PN16). Dim. A

Bolt Circle

Diameter

Dim. B

Bolt Hole

Diameter

Qty. N

Number of

Bolt Holes

2

2

Size

Same drilling as for ANSI B16.5 (Class 150) and ANSI B16.42 (Class 150).

1

1

0.75

(19,0)

0.91

(23,0) 0.75

(19,0)

0.59

(15,0)

TABLE A

DIMENSIONAL SPECIFICATIONS

FOR SELECTION OF FLANGE DRILLING