TFP1090

Page 10 of 22

Operating

Principles

Dry Pipe Valve

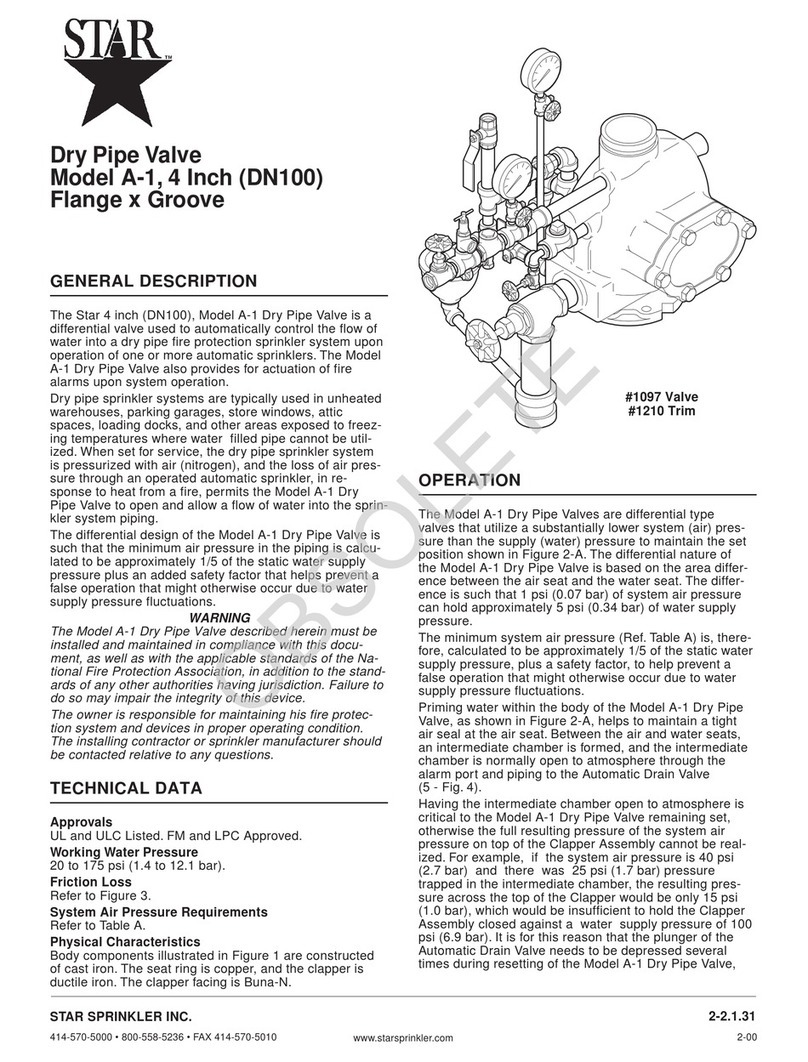

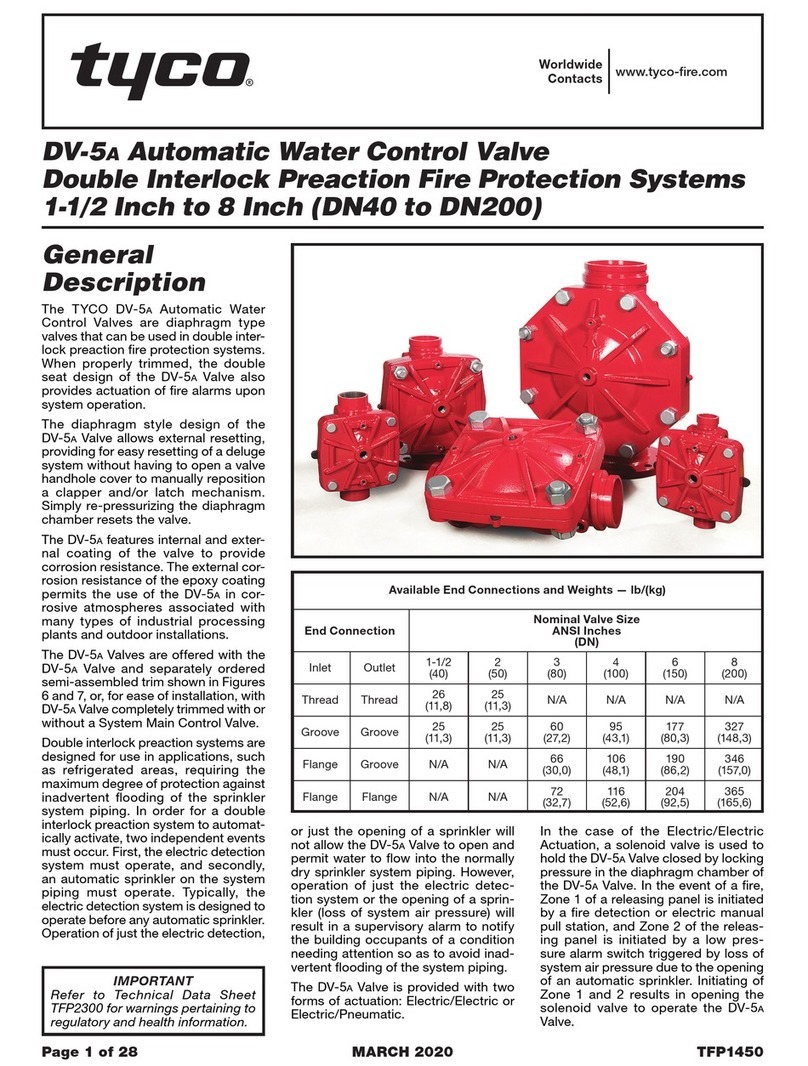

The TYCO Model DPV-1 Dry Pipe Valve

is a differential type valve that utilizes

a substantially lower system (air or ni-

trogen) pressure than the supply (wa-

ter) pressure, to maintain the set posi-

tion shown in Figure 4A. The differential

nature of the Model DPV-1 Dry Pipe

Valve is based on the area difference

between the air seat and the water seat

in combination with the ratio of the ra-

dial difference from the Hinge Pin to the

center of the Water Seat and the Hinge

Pin to the center of the Air Seat. The

difference is such that the Model DPV-1

has a nominal trip ratio of 5,5:1 (water

to air).

Table A establishes the minimum re-

quired system air pressure that includes

a safety factor to help prevent false op-

erations that occur due to water supply

uctuations.

The Intermediate Chamber of the

Model DPV-1 Dry Pipe Valve is formed

by the area between the Air Seat and

Water Seat as shown in Figure 4B. The

Intermediate Chamber normally re-

mains at atmospheric pressure through

the Alarm Port connection and the valve

trim to the normally open Automatic

Drain Valve (Ref. Figures 8 through

15). Having the Intermediate Chamber,

Figure 4B, open to atmosphere is criti-

cal to the Model DPV-1 Valve remaining

set, otherwise the full resulting pressure

of the system air pressure on top of the

Clapper Assembly cannot be realized.

For example, if the system air pres-

sure is 1,7 bar and there was 1,0 bar

pressure trapped in the Intermediate

Chamber, the resulting pressure across

the top of the Clapper would only be 0,7

bar. This pressure would be insufcient

to hold the Clapper Assembly closed

against a water supply pressure of 6,9

bar.

When one or more automatic sprin-

klers operate in response to a re,

air pressure within the system piping

is relieved through the open sprin-

klers. When the air pressure is suf-

ciently reduced, the water pressure

overcomes the differential holding

the Clapper Assembly closed and the

Clapper Assembly swings clear of the

water seat, as shown in Figure 4C. This

action permits water ow into the sys-

tem piping and subsequently to be

discharged from any open sprinklers.

Also, with the Clapper Assembly open,

the intermediate chamber is pressur-

ized and water ows through the Alarm

Port (Ref. Figure 4B) at the rear of the

Model DPV-1 Dry Pipe Valve. As the

ow through the Alarm Port exceeds

the drain capacity of the Automatic

Drain Valve, the alarm line is pres-

surized to actuate system water ow

alarms.

After a valve actuation and upon subse-

quent closing of a system Main Control

Valve to stop water ow, the Clapper

Assembly will latch open as shown

in Figure 4D. Latching open of the

Model DPV-1 Dry Pipe Valve will per-

mit complete draining of the system

(including any loose scale) through the

main drain port.

During the valve resetting procedure

and after the system is completely

drained, the external reset knob can

be easily depressed to externally un-

latch the Clapper Assembly as shown

in Figure 4E. As such, the Clapper

Assembly is returned to its normal set

position to facilitate setting of the dry

pipe sprinkler system, without having to

remove the Handhole Cover.

Accelerator

The Inlet Chamber of the TYCO Model

ACC-1 Dry Pipe Accelerator (Ref. Figure

6), is pressurized via its connection to

the system. The Pilot Chamber is, in

turn, pressurized through its inlet port

which is formed by the annular opening

around the lower tip of the Anti-Flood

Valve. As the Pilot Chamber increases

in pressure, the Differential Chamber

is pressurized through the Restriction.

The Accelerator is in its set position

while it is being pressurized as well

as after the Inlet, Pilot Chamber and

Differential Chamber pressures have

equalized. When in the Set position,

the Outlet Chamber is sealed off by

the Exhaust Valve which is held against

its seat by a combination of the Spring

pushing up against the Lever and the

net downward force exerted by the

pressure in the Pilot Chamber.

Both small and slow changes in system

pressure are accommodated by ow

through the Restriction. When, howev-

er, there is a rapid and steady drop in

system (that is, Inlet and Pilot Chamber)

pressure, the pressure in the Differential

Chamber reduces at a substantially

lower rate. This condition creates a net

downward force on the Plunger which

rotates the Lever. As the Lever is ro-

tated (Ref. Figure 7), the Relief Valve

is raised out of the Relief Port and the

Anti-Flood Valve is depressed down-

ward into the Pilot Chamber Inlet Port,

venting the Pilot Chamber.

The system pressure in the Inlet

Chamber then forces (raises) the

Exhaust Valve off its seat. This contin-

ues the rotation of the Lever into the

tripped (latched) position (Ref. Figure

7). As the Exhaust Valve is raised off

its seat, system pressure is transmitted

to the intermediate chamber of the Dry

Pipe Valve which neutralizes the dif-

ferential pressure holding the valve

closed.

Water and any water borne debris such

as silt is prevented from entering the

Pilot Chamber by virtue of the Anti-

Flood Valve having sealed off its inlet

port.

After the accelerator/Dry Pipe Valve

has tripped and the sprinkler system

has been drained, the piping from the

system to the Accelerator must also be

drained and the Accelerator reset/in-

spected according to the instructions

given in the Valve Setting Procedure

section.

The rate-of-ow through the

Restriction has been set such that

the Model ACC-1 Dry Pipe Valve

Accelerator provides the maximum

practical sensitivity to a loss in system

pressure due to a sprinkler operation

while still being capable of automatical-

ly compensating for normal variations

in system pressure such as are caused

by environmental temperature changes.

A test for verifying that the rate-of-ow

through the Restriction is within the

range for optimum Accelerator per-

formance is given in the Valve Setting

Procedure section.