TFP1515

Page 3 of 4

damage the seat material. Be sure to

center the valve and do not damage

the liner. Relax the separation of the

anges, install, and hand-tighten all

ange bolts. Slowly open the valve,

checking for free movement of the disc.

If valve opens freely, leave the valve in

the open position, and using a cross-

draw sequence, tighten all ange bolts

until the valve is metal-to-metal with

both mating anges. Recommended

tightening torques are listed in Table A.

Be certain to keep ange faces as paral-

lel as possible during and after tighten-

ing bolts or studs. After nal tightening,

again check the valve for full opening

and closing.

As applicable, refer to Figure 2 for the

internal switch wiring diagram.

Conduit and electrical connections

are to be made in accordance with the

authority having jurisdiction and/or the

National Electrical Code. With reference

to Figure 2, the supervisory switch is

intended for connection to the supervi-

sory circuit of a re alarm control panel

in accordance with NFPA 72. The auxil-

iary switch is intended for the unsuper-

vised connection to auxiliary equipment

in accordance with NFPA 70, National

Electric Code.

NOTE: For outdoor applications with

internal supervisory switches, it is rec-

ommended that wiring connections

be made at a temperature above 15°F

(-9°C), in order to insure sufficient flex-

ibility of the wire lead insulation.

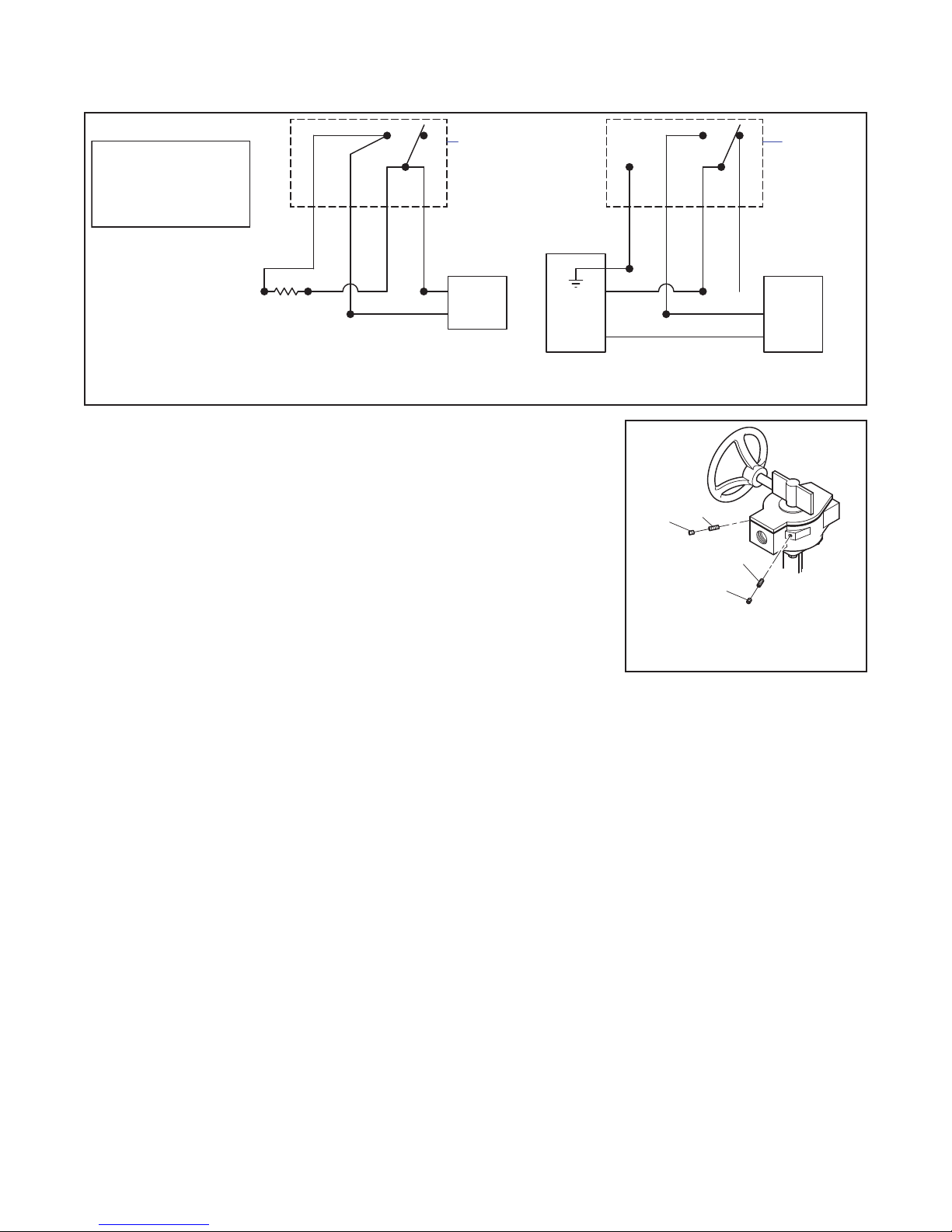

Stop Adjustment Procedure

The gear operator’s OPEN and SHUT

position have been factory set. The

following procedure should be used if

slight adjustments are needed. Refer to

Figure 3.

Step 1. Turn the Handwheel until the

valve is fully closed.

Step 2. Remove the two Lock Screws

(A) from the gear operator body.

Step 3. Turn the Shut Stop Screw (B)

clockwise until snug.

Step 4. Turn the Handwheel until the

valve is fully open.

Step 5. Turn the Open Stop Screw (C)

clockwise until snug.

Step 6. Close the valve by turning the

Handwheel until the valve is fully in

the closed position. Ensure the disc

has returned to the fully closed posi-

tion and the disc is centered in the seat

area. Readjust the Shut Stop Screw if

necessary.

Step 7. Replace the two Lock Screws

(A) into the gear operator body, locking

the stops into position.

Care and

Maintenance

The TYCO Model BFV-N Wafer Style

Buttery Valves must be maintained

and serviced in accordance with this

section.

Before closing a re protection system

control valve for maintenance or inspec-

tion work on either the valve or re

protection system which it controls, per-

mission to shut down the affected re

protection systems must be obtained

from the proper authorities and all per-

sonnel who may be affected by this

decision must be notied.

The owner is responsible for the

inspection, testing, and maintenance of

their re protection system and devices

in accordance with the applicable stan-

dards of the National Fire Protection

Association (e.g., NFPA 25), in addi-

tion to the standards of any authority

having jurisdiction. Contact the install-

ing contractor or product manufacturer

with any questions. Any impairment

must be immediately corrected.

It is recommended that automatic

sprinkler systems be inspected, tested,

and maintained by a qualied inspec-

tion service.

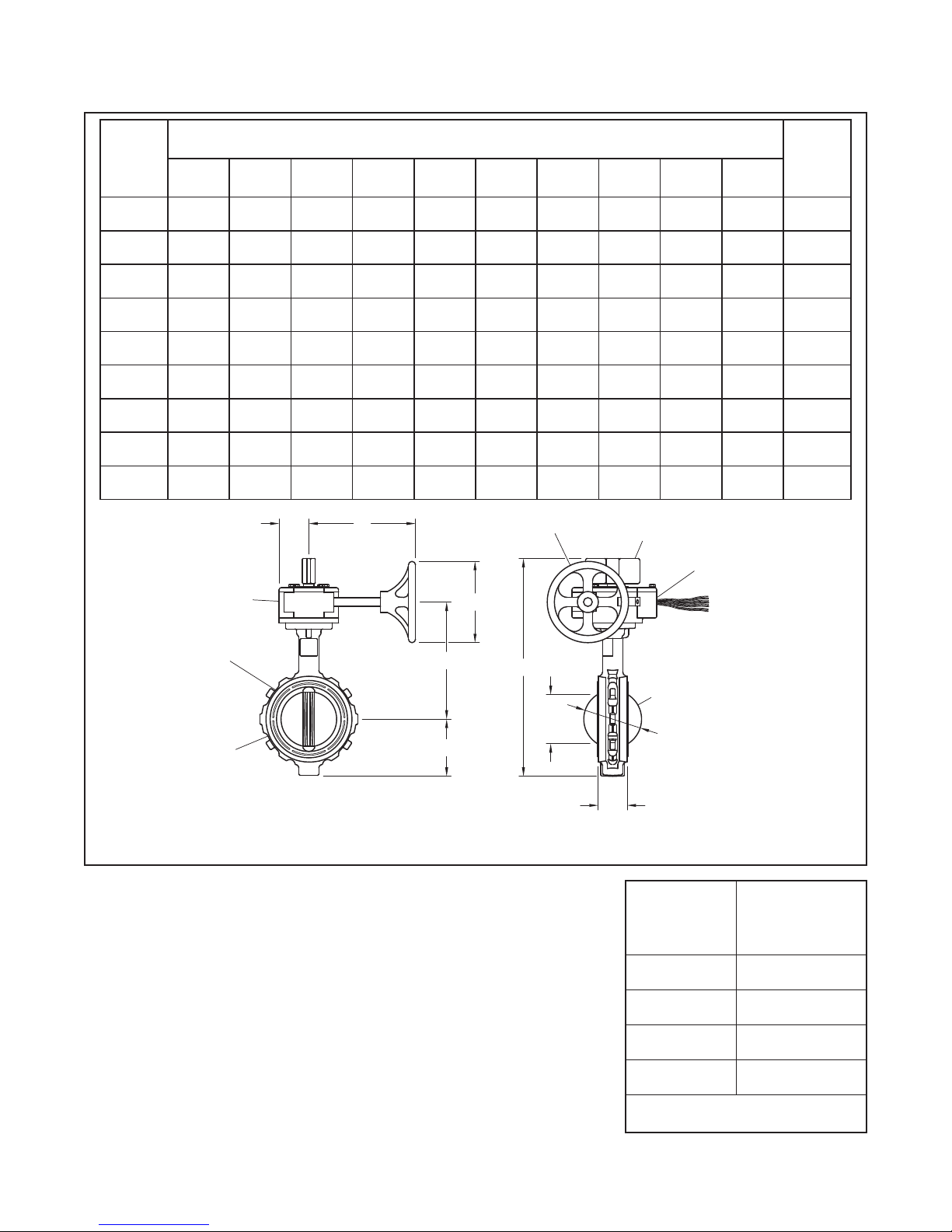

1/2A @ 125 VDC

1/4A @ 250 VDC

15.1A/12HP @ 125, 250 VAC

5A @ 125 VAC "L"

END OF LINE

RESISTOR

PANEL

ORANGE

ORANGE

YELLOW

YELLOW

SUPERVISORY

SWITCH

SWITCH SHOWN

WITH VALVE

FULL OPEN

GREEN

VIOLET

AUXILIARY

WITH VALVE

FULL OPEN

BLUE

RED

BELL

SWITCH

GND

POWER

+

- -

+

CONTACT RATING:

AC

A

B

OPEN

FIGURE 2

MODEL BFV-N BUTTERFLY VALVE

INTERNAL SWITCH WIRING DIAGRAM WITH VALVE IN OPEN POSITION

FIGURE 3

MODEL BFV-N WAFER STYLE

BUTTERFLY VALVE

OPERATOR ADJUSTMENT