TFP1315

Page 10 of 16

Gauge Test Valve. Bronze body per

ASTM B584.

Manual Control Station. Corrosion

resistant copper alloys and glass lled

PTFE seals. Thermoplastic enclosure.

Automatic Drain Valve. Brass body

per ASTM B584, Type 440 stainless

steel or brass per ASTM B134 Ball, and

galvanized steel inlet.

Automatic Shut-Off Valve. Brass

body, cover, and center seat per UNS

C36000, Type 316 stainless steel

spring, and Nylon fabric reinforced,

natural rubber diaphragm per ASTM

D2000.

Ball Valve. Corrosion resistant copper

alloys and glass lled PTFE seals.

Spring Loaded Check Valve. Brass

body and buna-n seal.

Y-Strainer. Bronze body per ASTM

B584 and Type 304 stainless steel

screen.

Swing Check Valve. Bronze body per

ASTM B584 and buna-n seal.

Angle Valve. Bronze body per ASTM

B584 and nitrile disc (TEFLON disc for

2 inch size valve).

3/32” Vent Fitting. Brass per ASTM

B16.

Tubing Connector. Brass per ASTM

B16.

Tubing. Type L copper per ASTM B88.

Dry Pilot Actuator. Bronze body per

ASTM B62, Type 302 stainless steel

spring, Type 304 seat and guide, brass

per ASTM diaphragm retainer, nitrile

diaphragm, and buna-n seal.

Globe Valve. Bronze body per ASTM

B584 and nitrile disc.

Pressure Relief Valve. Brass body,

stainless steel spring, and buna-n disc.

Pipe Fittings. Galvanized mallea-

ble iron per ANSI B16.3 or cast iron

per ANSI B16.4; black malleable iron

per ANSI B16.3 or cast iron per ANSI

B16.4; or, bronze per ANSI B16.15.

Pipe Nipples. Schedule 40 galvanized

steel per ASTM A53 or A135; Sched-

ule 40 black steel per ASTM A53 or

A135; or, Schedule 40 red brass pipe

per ASTM B43.

Installation

General Instructions

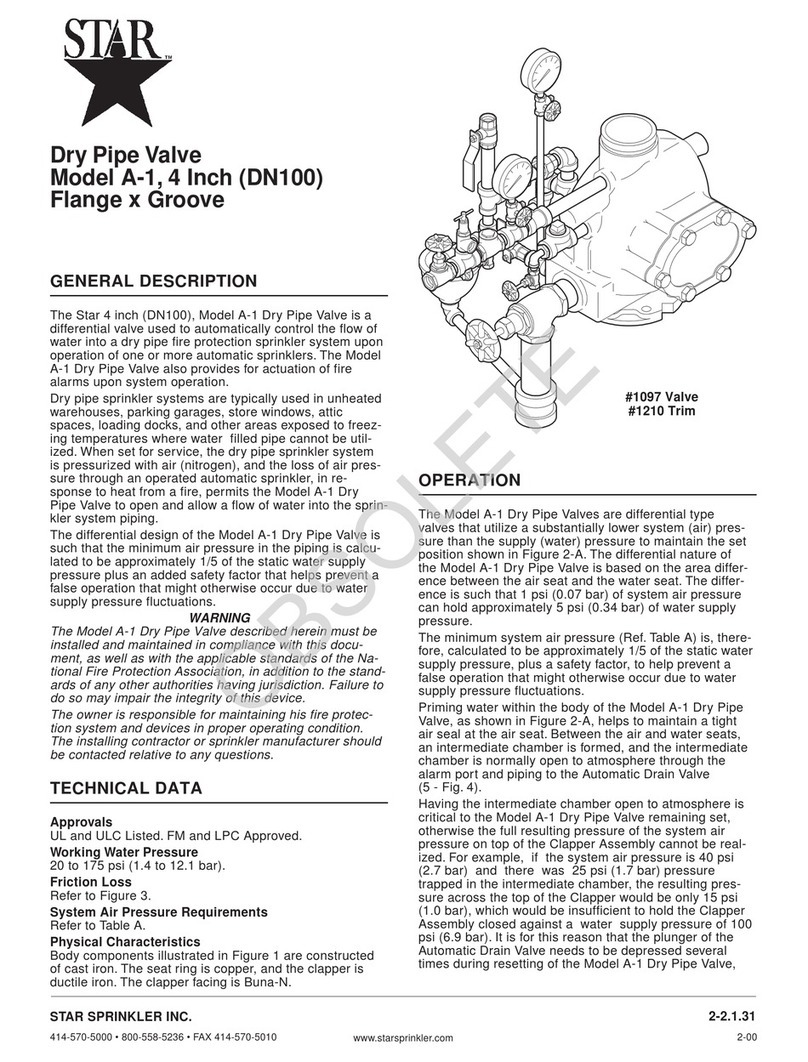

Proper operation of the DV-5 Deluge

Valves depends upon their trim being

installed in accordance with the in-

structions given in this Technical Data

Sheet. Failure to follow the appropri-

ate trim diagram may prevent the DV-5

Valve from functioning properly, as well

as void listings, approvals, and the

manufacturer’s warranties.

The DV-5 Valve must be installed in a

readily visible and accessible location.

The DV-5 Valve and associated trim

must be maintained at a minimum tem-

perature of 40°F (4°C).

Heat tracing of the DV-5 Valve or its

associated trim is not permitted. Heat

tracing can result in the formation of

hardened mineral deposits that are ca-

pable of preventing proper operation.

The DV-5 Deluge Valve is to be in-

stalled in accordance with the follow-

ing criteria:

Step 1. All nipples, ttings, and de-

vices must be clean and free of scale

and burrs before installation. Use pipe

thread sealant sparingly on male pipe

threads only.

Step 2. The DV-5 Valve must be

trimmed in accordance with Figure

3A/3B or 5.

Step 3. Care must be taken to ensure

that check valves, strainers, globe

valves, etc. are installed with the ow

arrows in the proper direction.

Step 4. Drain tubing to the Drip Funnel

must be installed with smooth bends

that will not restrict ow.

Step 5. The main drain and Drip Funnel

drain may be interconnected provided

a check valve is located at least 12

inches (300 mm) below the Drip Funnel.

Step 6. Suitable provision must be

made for disposal of drain water. Drain-

age water must be directed such that

it will not cause accidental damage to

property or danger to persons.

Step 7. Connect the Diaphragm Cham

-

ber Supply Control Valve to the inlet

side of the system’s Main Control Valve

in order to facilitate setting of the DV-5

Valve (Ref. Figure 4).

Step 8. An Inspector’s Test Connec-

tion, as described in the Technical Data

section, must be provided for Dry Pilot

Actuation systems.

Step 9. An Air Maintenance Device, as

described in the Technical Data Sec-

tion, must be provided for Dry Pilot

Actuation.

Step 10. A desiccant dryer, when

specied for Dry Pilot Actuation, is to

be installed between a drip leg and the

Air Maintenance Device.

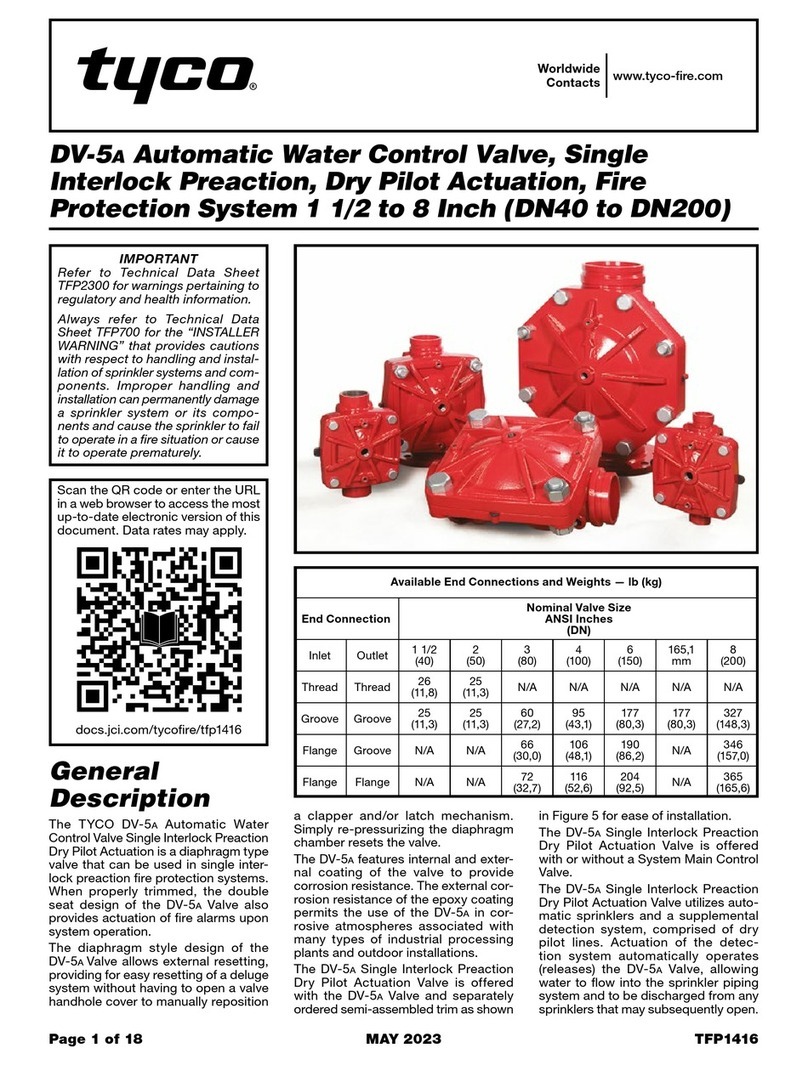

Step 11. The Low Pressure Alarm

Switch for Dry Pilot Actuation is to be

adjusted as follows:

•

Low pressure alarm setting at ap-

proximately 6 psi (0,4 bar) below the

minimum pilot line service pressure

requirement shown in Graph A

•

Fire alarm setting at approximately

15 psi (1,0 bar) below the minimum

pilot line service pressure require-

ment shown in Graph A

Step 12. Unused pressure alarm

switch connections must be plugged.

Step 13. The Pressure Relief Valve pro-

vided with the Dry Pilot Actuation Trim

is factory set to relieve at a pressure

Continued on Page 14

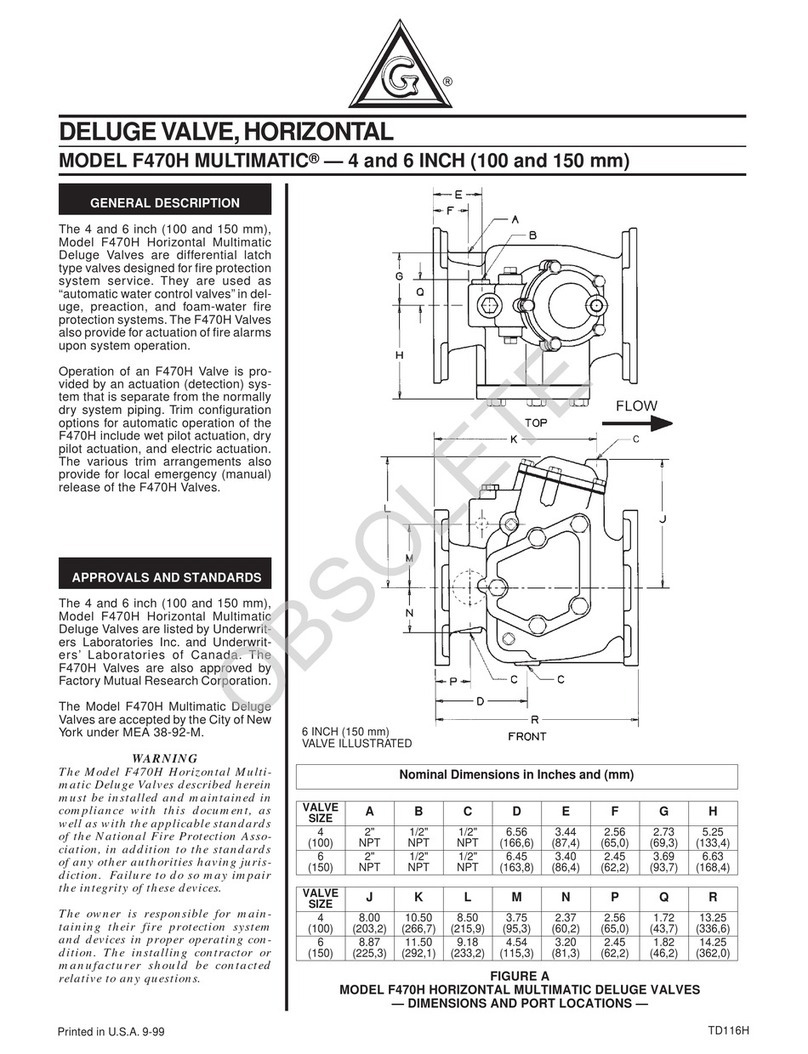

WATER SUPPLY PRESSURE IN PSI

100

RANGE OF ACTUATOR OPENING PRESSURE

MINIMUM SYSTEM AIR PRESSURE

20 60

15

0

30

140 180

200

GRAPH A

DV-5 DELUGE VALVE

DRY PILOT LINE PRESSURE REQUIREMENTS