age or impairment of the sprinkler.

Do not attempt to compensate for im-

proper location of the sprinkler fitting

by under- or over-tightening the sprin-

kler. Readjust the position of the sprin-

kler fitting to suit, or increase or de-

crease the number of Model 1752

Spacers, as applicable.

After the installation is complete, make

certain that the Institutional Escutch-

eon is held fast to the mounting sur-

face and that it sits squarely against

the ceiling around its entire perimeter.

Step 1. The TFP PH5 Sprinklers must

be installed horizontally with the cen-

terline of their waterway perpendicular

to the back wall surface, and the De-

flector must be located with the top

towards the ceiling (Ref. Figure 1).

Step 2. With the Institutional Escutch-

eon in place and with pipe thread

sealant applied to the pipe threads,

hand tighten the sprinkler into the

sprinkler fitting.

Step 3. Wrench tighten the Sprinkler

using only the Model 1509-3 Sprin-

kler Wrench (Ref. Fig. 5). The wrench-

ing teeth of the Sprinkler Wrench are

to be applied to the sprinkler wrench-

ing notch areas (Ref. Fig. 1).

Step 4. After the installation is com-

plete, make certain that the Institu-

tional Escutcheon is held fast to the

mounting surface and that it sits

squarely against the wall around its

entire perimeter.

NOTE

The Sprinkler Body must not extend

beyond the Institutional Escutcheon

(Ref. Fig. 4). Otherwise the tamper

resistant design of the Model TFP PH5

will be compromised.

Care and

Maintenance

The 5.6 K-factor, Model TFP PH5

Sprinklers must be maintained and

serviced in accordance with the follow-

ing instructions:

NOTES

Service inspections should be made

on a regular basis to detect possible

damage or alterations to the sprinkler

and escutcheon. Inspections should

include making certain that the Institu-

tional Escutcheon is held fast to the

mounting surface. Damaged or altered

sprinklers are to be replaced immedi-

ately to avoid personal injury and to

prevent use for causing personal in-

jury, as well as to maintain the sprin-

kler system in an operative condition.

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

it controls, permission to shut down the

affected fire protection systems must

be obtained from the proper authori-

ties and all personnel who may be

affected by this action must be notified.

Sprinklers that are found to be leaking

or exhibiting visible signs of corrosion

must be replaced.

Automatic sprinklers must never be

shipped or stored where their tempera-

tures will exceed 100°F/38°C and they

must never be painted, plated, coated,

or otherwise altered after leaving the

factory. Modified or over-heated sprin-

klers must be replaced.

Care must be exercised to avoid dam-

age to the sprinklers - before, during,

and after installation. Sprinklers dam-

aged by dropping, striking, wrench

twist/slippage, or the like, must be re-

placed.

The owner is responsible for the in-

spection, testing, and maintenance of

their fire protection system and de-

vices in compliance with this docu-

ment, as well as with the applicable

standards of the National Fire Protec-

tion Association (e.g., NFPA 25), in

TFP654 Page 3 of 4

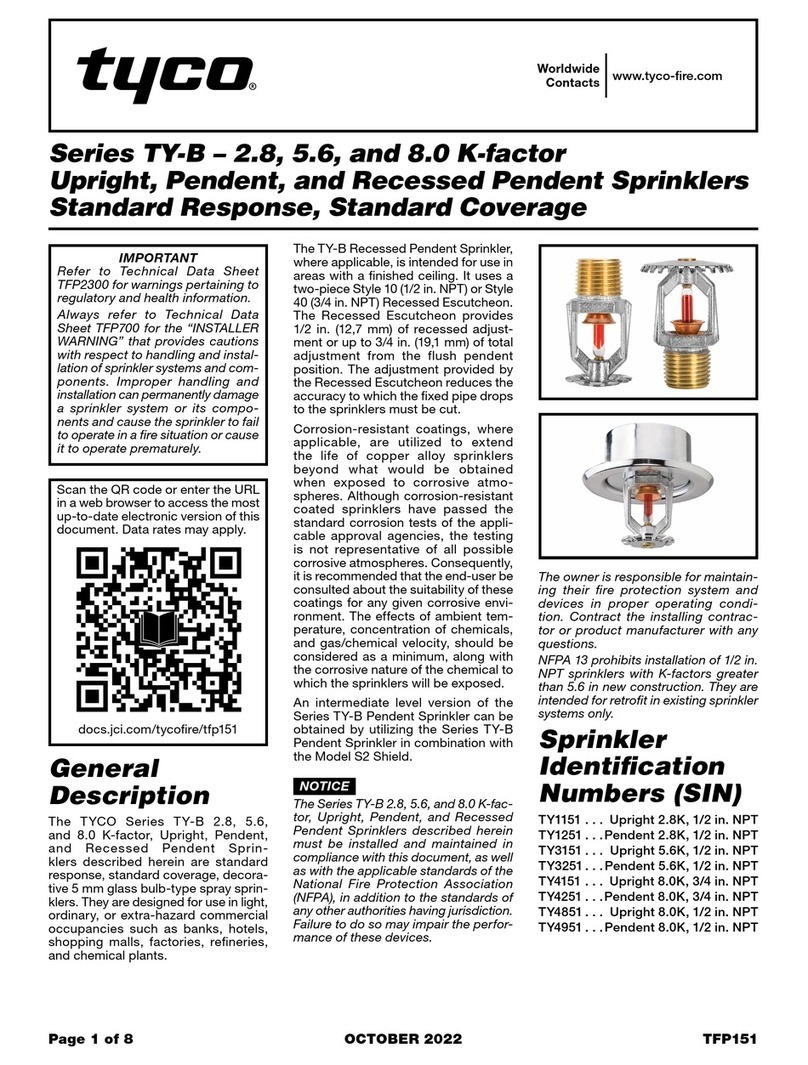

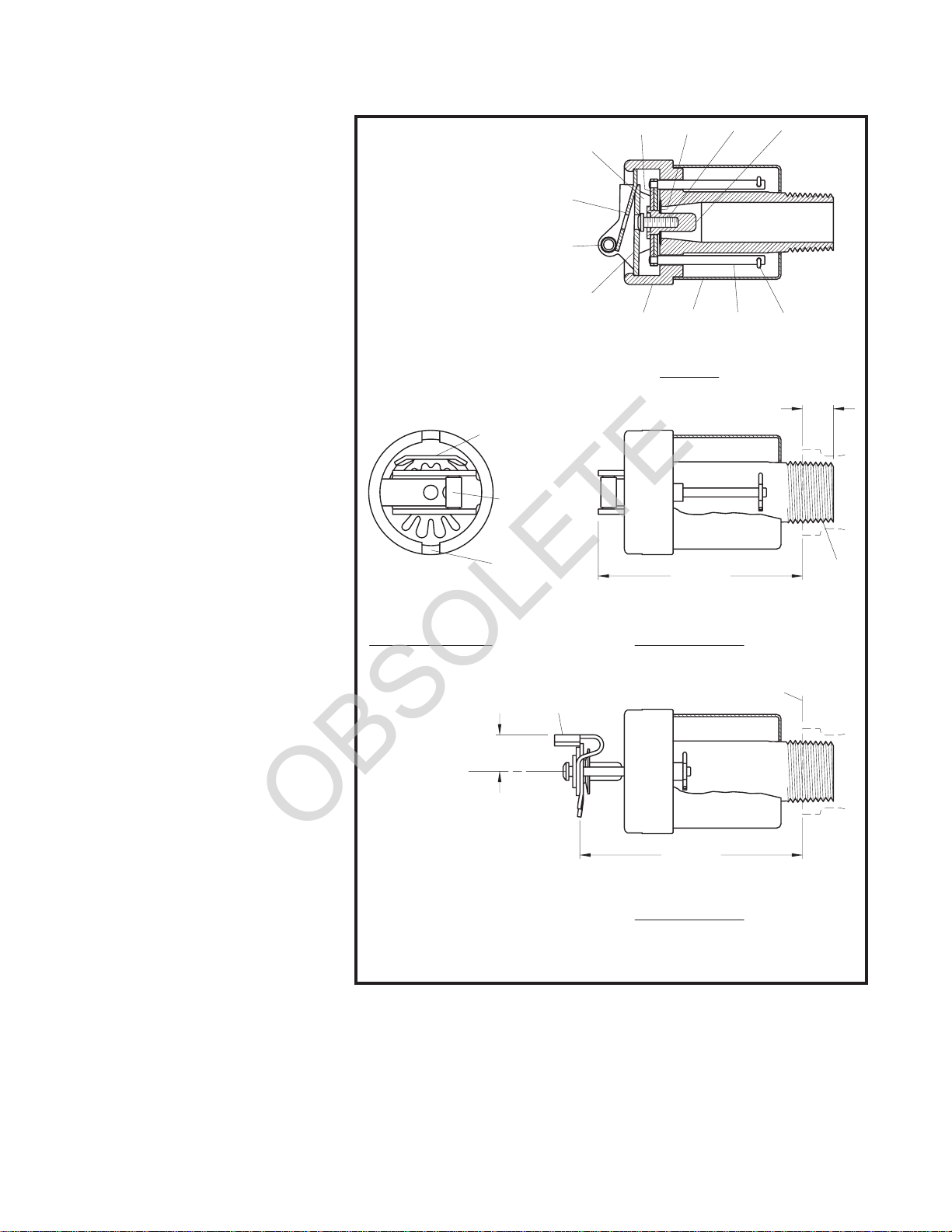

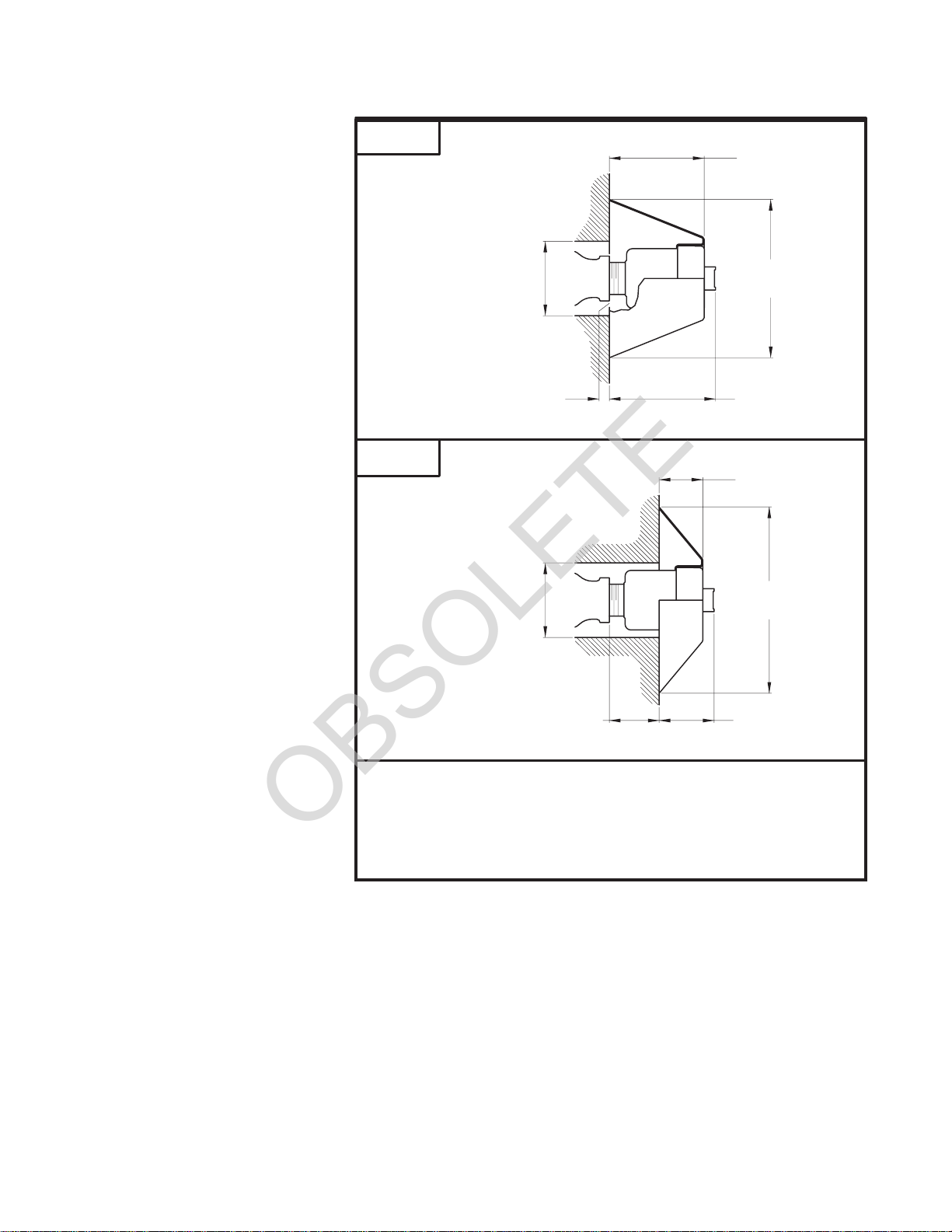

FIGURE 3

INSTITUTIONAL ESCUTCHEON OPTIONS

FOR USE WITH THE MODEL TFP PH5

NOTE: Model 1752 Spacers are not to be used to obtain horizontal adjustment for the

Model TFP PH5 with Style B2 or C Escutcheons.

CLEARANCE FOR

DETERMINED BY

DIAMETER

REDUCING

COUPLING

CLEARANCE FOR

DETERMINED BY

MOUNTING SURFACE

FITTING FLUSH WITH

FACE OF SPRINKLER

DIAMETER

REDUCING

COUPLING

(71.4 mm)

4-1/4" DIA.

(108.0 mm)

2.81"

(65.1 mm)

2-9/16"

1-3/16"

(30.2 mm)

5" DIA.

(127.0 mm)

(37.6 mm)

(33.8 mm)

1.33" 1.48"

STYLE B2

STYLE C