Worldwide

Contacts

www.tyco-fire.com

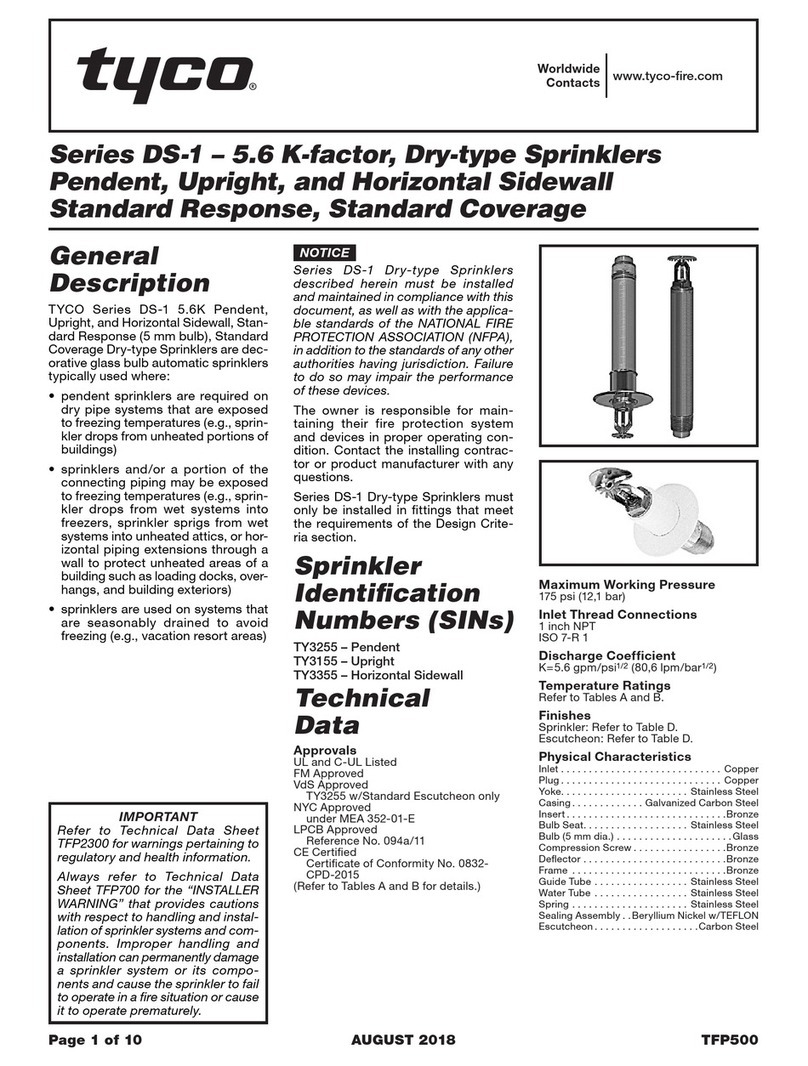

General

Description

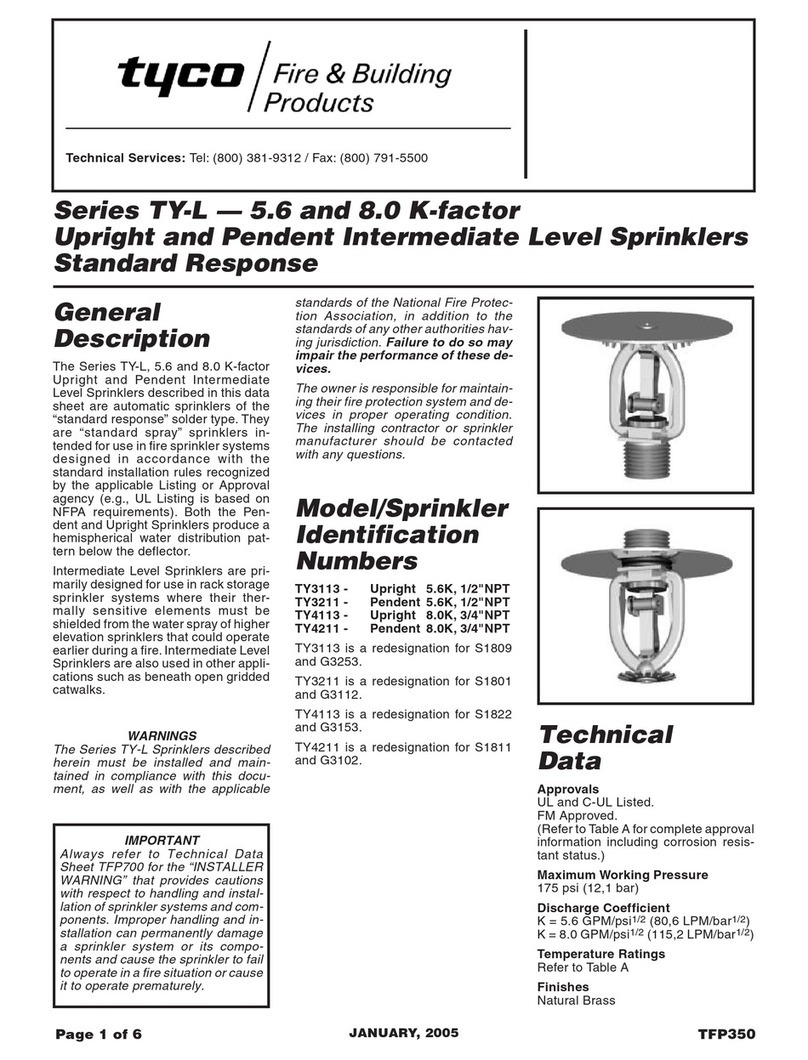

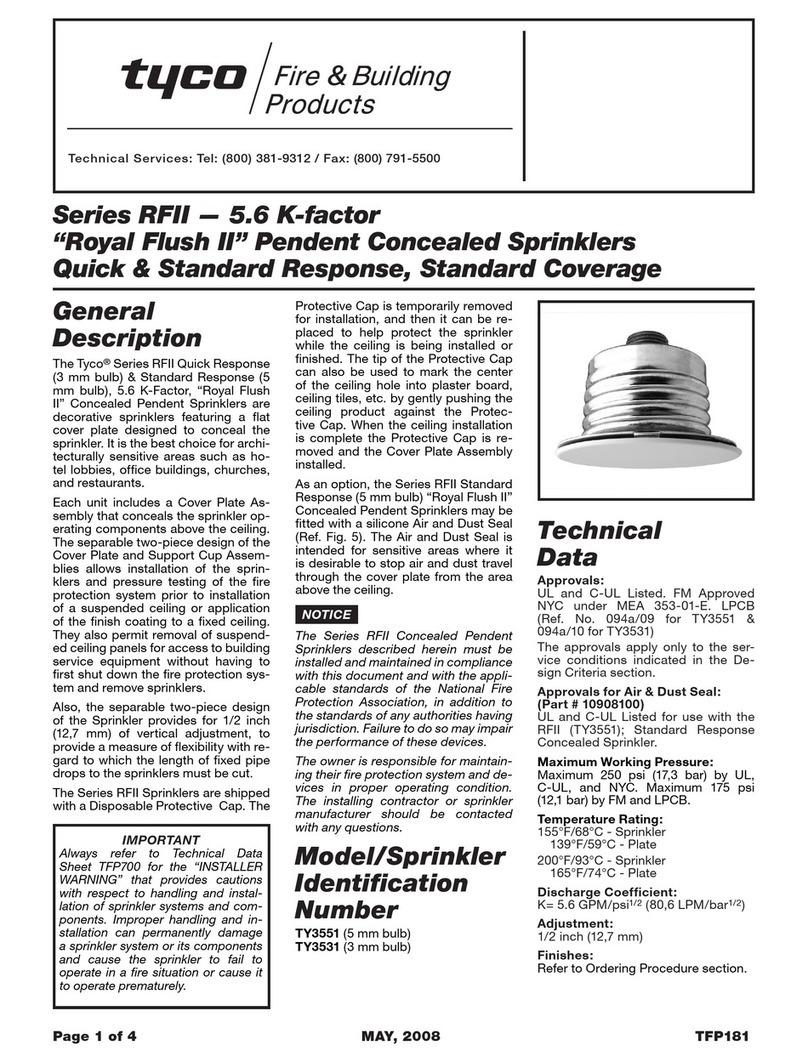

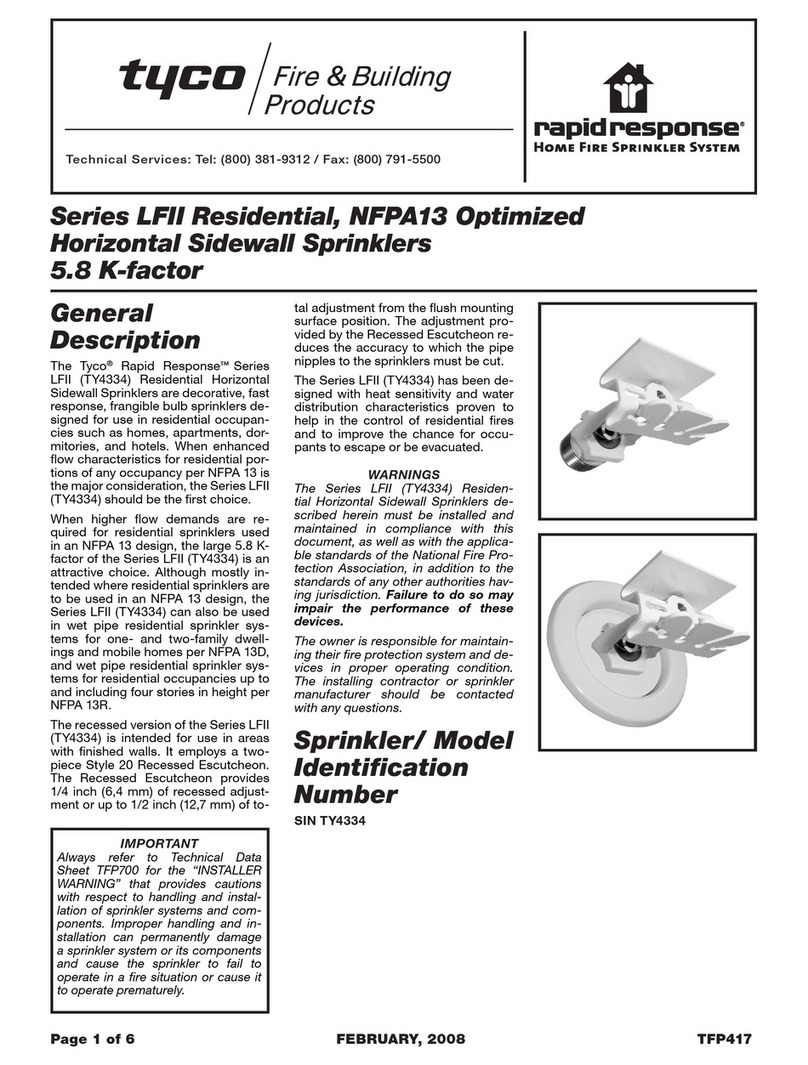

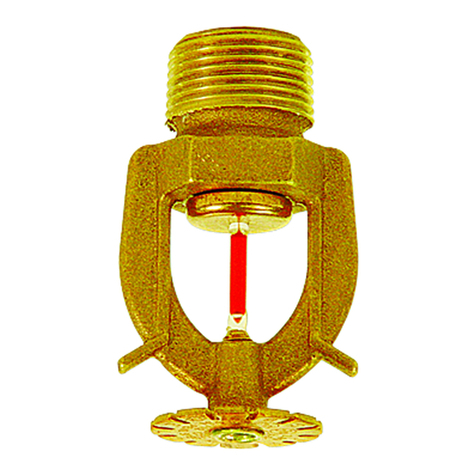

The Series TY-FRL, 2.8, 5.6, and 8.0 K-

factor, Upright and Pendent Sprinklers

described in this data sheet are quick

response -standard coverage, solder

type spray sprinklers designed for use

in light and ordinary hazard, commer-

cial occupancies such as banks, ho-

tels, shopping malls, schools, hospi-

tals, etc.

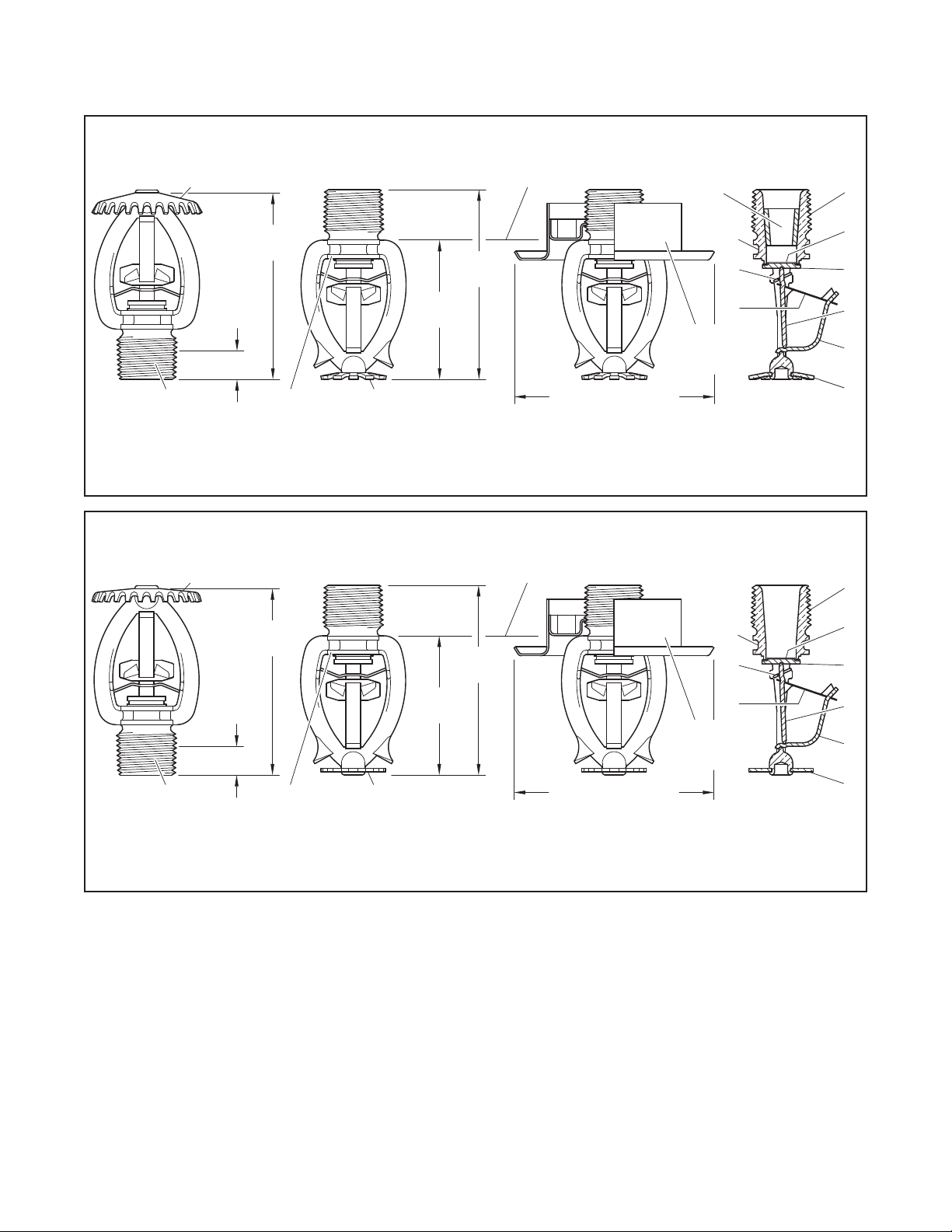

The recessed version of the 2.8 and

5.6 K-factor, Series TY-FRL Pendent

Sprinkler, where applicable, is intend-

ed for use in areas with a finished ceil-

ing. It uses a two-piece Style 20 (1/2

inch NPT) Recessed Escutcheon. The

Recessed Escutcheon provides 1/4

inch (6,4 mm) of recessed adjustment

or up to 1/2 inch (12,7 mm) of total ad-

justment from the flush pen-dent po-

sition. The adjustment provided by

the Recessed Escutcheon reduces

the accuracy to which the fixed pipe

drops to the sprinklers must be cut.

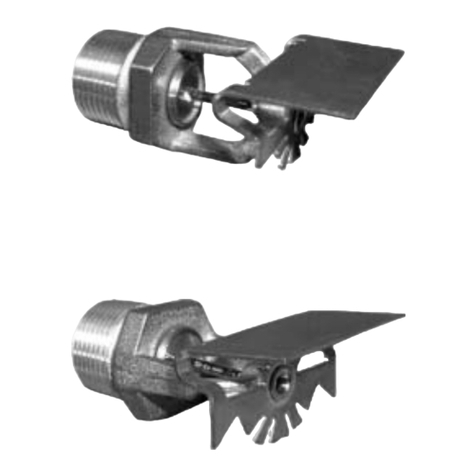

An intermediate level version of the

5.6 and 8.0 K-factor, Series TY-FRL

Pendent Sprinkler can be obtained

by utilizing the Series TY-FRL Pen-

dent Sprinkler in combination with the

Model S4 Shield.

NOTICE

The Series TY-FRL Sprinklers de-

scribed herein must be installed and

maintained in compliance with this

document, as well as with the appli-

cable standards of the National Fire

Protection Association, in addition to

the standards of any other authorities

having jurisdiction. Failure to do so

may impair the performance of these

devices.

The owner is responsible for maintain-

ing their fire protection system and

devices in proper operating condi-

tion. The installing contractor or sprin-

kler manufacturer should be contact-

ed with any questions.

Sprinkler

Identification

Numbers

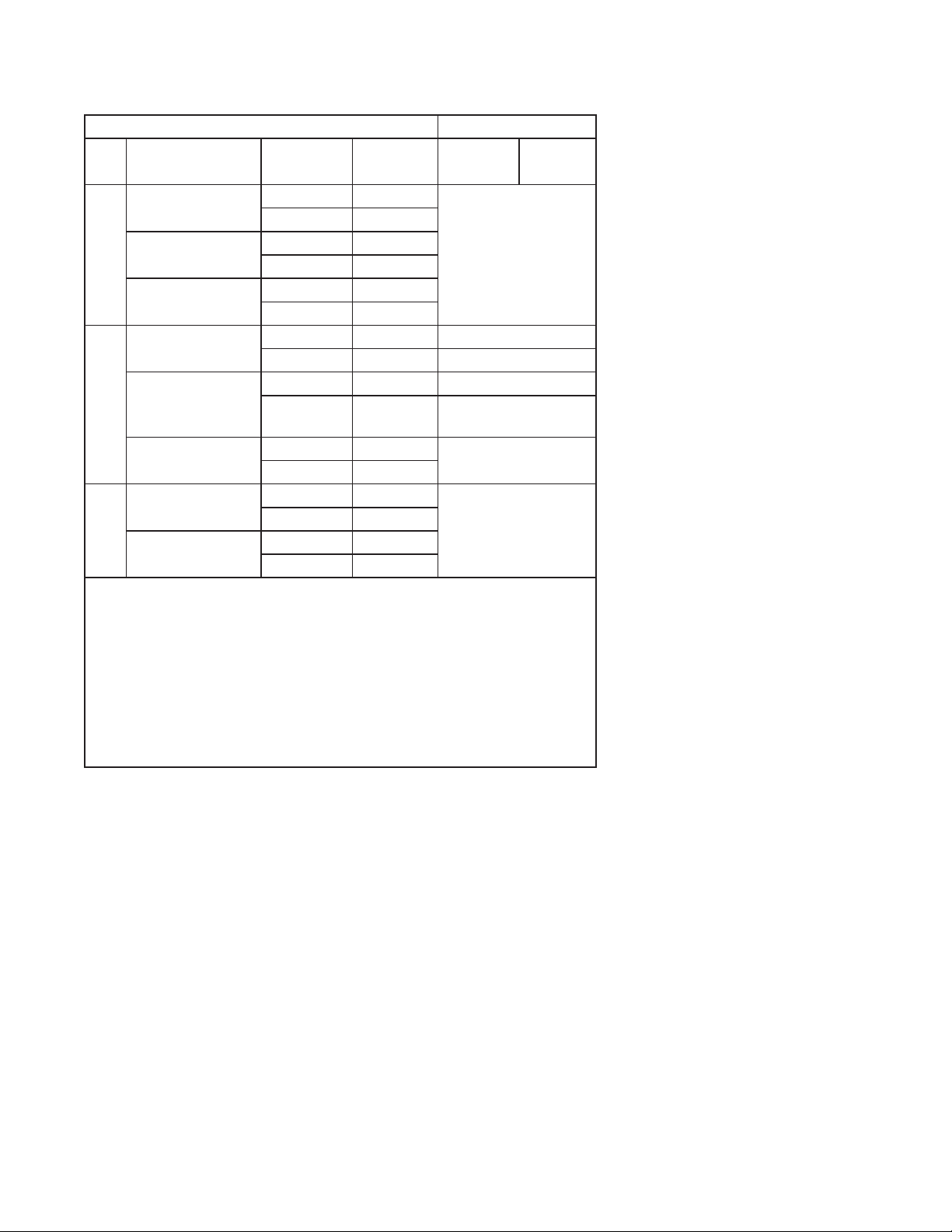

T Y112 1. . . . . . Upright 2.8K, 1/2”NPT

TY1221 ....Pendent 2.8K, 1/2”NPT

TY3121 .....Upright 5.6K, 1/2”NPT

TY3221 .... Pendent 5.6K, 1/2”NPT

TY4121......Upright 8.0K, 3/4”NPT

TY4221 .... Pendent 8.0K, 3/4”NPT

TY1121 is a redesignation for S1879

and G8973.

TY1221 is a redesignation for S1880

and G8971.

TY3121 is a redesignation for S1864

and G8974.

TY3221 is a redesignation for S1865

and G8972.

TY4121 is a redesignation for S1866

and G8174.

TY4221 is a redesignation for S1867

and G8172.

Series TY-FRL — 2.8, 5.6, and 8.0 K-factor

Upright, Pendent, and Recessed Pendent Sprinklers

Quick Response, Standard Coverage

Page 1 of 6 MARCH 2013 TFP130

Worldwide

Contacts

www.tyco-fire.com

IMPORTANT

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and instal-

lation of sprinkler systems and com-

ponents. Improper handling and in-

stallation can permanently damage

a sprinkler system or its compo-

nents and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.