Copyright © 2006-2011 Tyco Fire Suppression & Building Products. All rights reserved.

TFP400

Page 8 of 8

Care and

Maintenance

The RAPID RESPONSE Series LFII

Residential Pendent and Recessed

Pendent Sprinklers (TY2234) must be

maintained and serviced in accordance

with the following instructions.

NOTICE

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system

that it controls, obtain permission to

shut down the affected fire protection

systems from the proper authorities

and notify all personnel who may be

affected by this action.

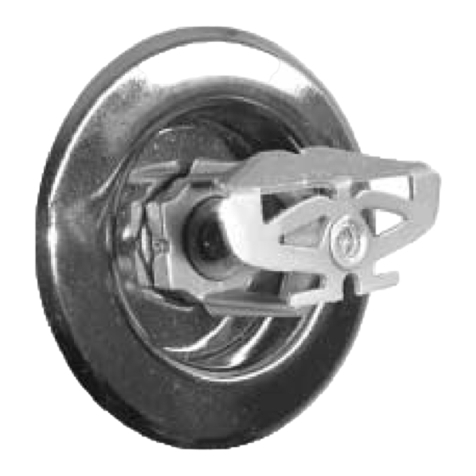

Absence of the outer piece of an

escutcheon, which is used to cover

a clearance hole, can delay sprinkler

operation in a fire situation.

Owners must assure that the sprin-

klers are not used for hanging of any

objects and that the sprinklers are only

cleaned by means of gently dusting

with a feather duster; otherwise, non-

operation in the event of a fire or inad-

vertent operation may result.

Exercise care to avoid damage to

sprinklers before, during, and after

installation. Never paint, plate, coat,

or otherwise alter automatic sprinklers

after they leave the factory.

Replace sprinklers that:

• were modied or over-heated.

•

were damaged by dropping, striking,

wrench twisting, wrench slippage, or

the like.

•

are leaking or exhibiting visible signs

of corrosion.

•

were exposed to corrosive

products of combustion but have

not operated, if you cannot easily

remove combustion by-products

with a cloth.

•

have a cracked bulb or have lost

liquid from the bulb. Refer to the

Installation section in this data sheet.

Initial and frequent visual inspections of

random samples are recommended for

corrosion-resistant sprinklers to verify

the integrity of the corrosion-resistant

material

of construction. Thereafter,

annual inspections per NFPA 25 should

sufce.

Inspections of corrosion-resis-

tant sprinklers are recommended at

close range, instead of from the oor

level per NFPA. Inspection at close

range can better determine the exact

sprinkler condition and the long-term

integrity of the corrosion-resistant

material, which can be affected by the

corrosive conditions present.

Responsibility lies with the owner for

the inspection, testing, and mainte-

nance of their re protection system

and devices in compliance with this

document, as well as with the appli-

cable standards of the National Fire

Protection Association (that is, NFPA

25), in addition to the standards of any

authorities having jurisdiction. Contact

the installing contractor or sprinkler

manufacturer regarding any questions.

Automatic sprinkler systems are

recommended to be inspected,

tested, and maintained by a qualied

Inspection Service in accordance with

local requirements and/or national

codes.

Limited

Warranty

Products manufactured by Tyco Fire

Suppression & Building Products

(TFSBP) are warranted solely to the

original Buyer for ten (10) years against

defects in material and workmanship

when paid for and properly installed

and maintained under normal use

and service. This warranty will expire

ten (10) years from date of shipment

by TFSBP. No warranty is given for

products or components manufac-

tured by companies not afliated by

ownership with TFSBP or for products

and components which have been

subject to misuse, improper instal-

lation, corrosion, or which have not

been installed, maintained, modied

or repaired in accordance with appli-

cable Standards of the National Fire

Protection Association, and/or the

standards of any other Authorities

Having Jurisdiction. Materials found by

TFSBP to be defective shall be either

repaired or replaced, at TFSBP’s sole

option. TFSBP neither assumes, nor

authorizes any person to assume for

it, any other obligation in connection

with the sale of products or parts of

products. TFSBP shall not be respon-

sible for sprinkler system design errors

or inaccurate or incomplete infor-

mation supplied by Buyer or Buyer’s

representatives.

In no event shall TFSBP be liable, in

contract, tort, strict liability or under

any other legal theory, for incidental,

indirect, special or consequential

damages, including but not limited to

labor charges, regardless of whether

TFSBP was informed about the possi-

bility of such damages, and in no

event shall TFSBP’s liability exceed an

amount equal to the sales price.

The foregoing warranty is made in

lieu of any and all other warranties,

express or implied, including warran-

ties of merchantability and tness for a

particular purpose.

This limited warranty sets forth the

exclusive remedy for claims based

on failure of or defect in products,

materials or components, whether the

claim is made in contract, tort, strict

liability or any other legal theory.

This warranty will apply to the full

extent permitted by law. The invalidity,

in whole or part, of any portion of this

warranty will not affect the remainder.

Ordering

Procedure

Contact your local distributor for

availability. When placing an order,

indicate the full product name and Part

Number (P/N).

Sprinkler Assembly

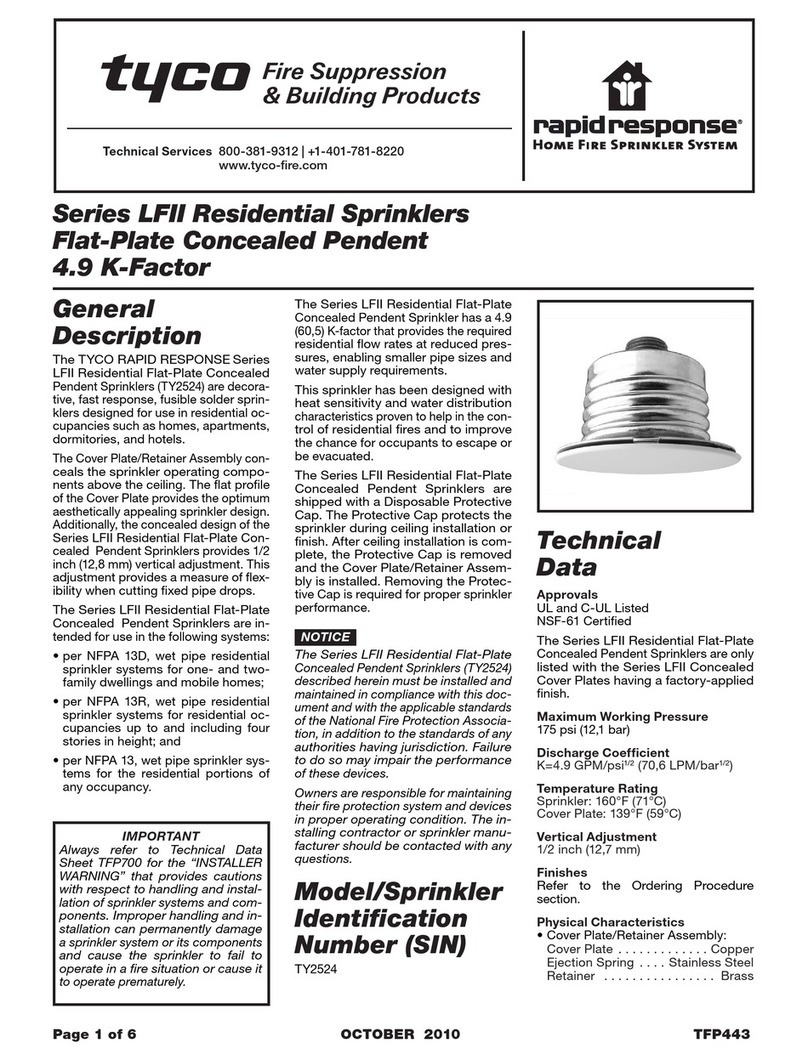

Specify Series LFII Residential Pendent

and Recessed Pendent Sprinkler

(TY2234), K=4.9, with (temperature

rating), (nish), and P/N (below).

155°F (68°C) or

Chrome Plated . . . . . . . . . . . . P/N 51-201-9-155

155°F (68°C)

White Polyester . . . . . . . . . . . . P/N 51-201-4-155

155°F (68°C)

White

(RAL9010)*. . . . . . . . . . . . . . . . P/N 51-201-3-155

155°F (68°C)

Natural Brass. . . . . . . . . . . . . . P/N 51-201-1-155

175°F (79°C) or

Chrome Plated . . . . . . . . . . . . P/N 51-201-9-175

175°F ( 79°C)

White Polyester . . . . . . . . . . . . P/N 51-201-4-175

175°F ( 79°C)

White

(RAL9010)*. . . . . . . . . . . . . . . . P/N 51-201-3-175

175°F ( 79°C)

Natural Brass. . . . . . . . . . . . . . P/N 51-201-1-175

*Eastern Hemisphere sales only.

Recessed Escutcheon

Specify Style 20 Recessed Escutcheon

with nish and P/N. Refer to Technical

Data Sheet TFP770.

Sprinkler Wrench

Specify W-Type 6 Sprinkler Wrench,

P/N 56-000-6-387.

Specify W-Type 7 Sprinkler Wrench,

P/N 56-850-4-001.