General

Description

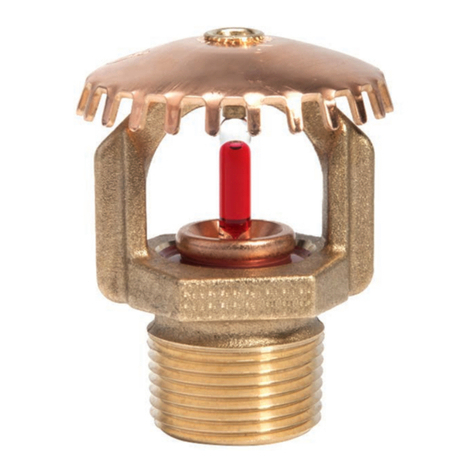

The Model TFP MAX, 5.6 K-factor, In-

stitutional Horizontal Sidewall Sprin-

klers are quick response - standard

coverage, spray sprinklers designed

for use in areas such as correctional,

detention, and mental health care fa-

cilities.

The unique features of the Model TFP

MAX provide a tamper resistant sprin-

kler design that helps eliminate the

opportunity for individuals to injure

themselves or others with components

of a fire sprinkler. At the same time, the

Model TFP MAX optimizes an aes-

thetically appealing flush design that

conceals most of the operating parts,

and provides added protection for the

heat sensitive glass bulb element.

WARNING

The Model TFP MAX Institutional Hori-

zontal Sidewall Sprinklers described

herein must be installed and main-

tained in compliance with this docu-

ment, as well as with the applicable

standards of the National Fire Protec-

tion Association, in addition to the

standards of any other authorities hav-

ing jurisdiction. Failure to do so may

impair the integrity of these devices.

The owner is responsible for maintain-

ing their fire protection system and de-

vices in proper operating condition.

The installing contractor or manufac-

turer should be contacted relative to

any questions.

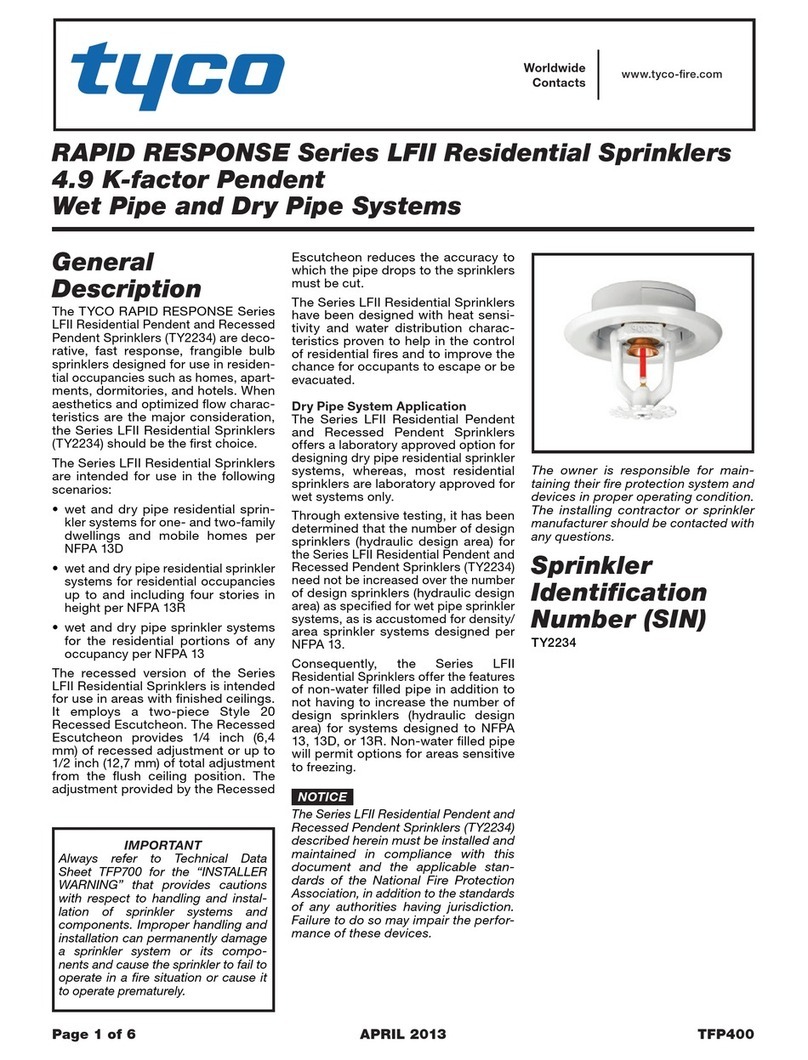

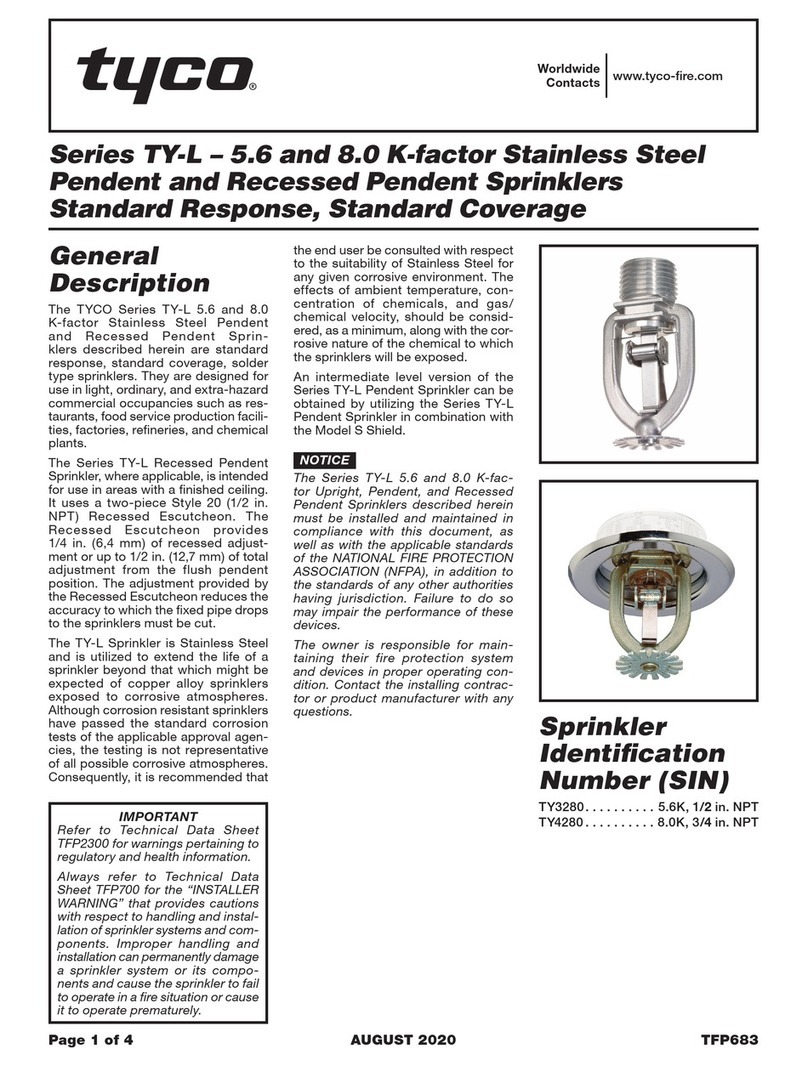

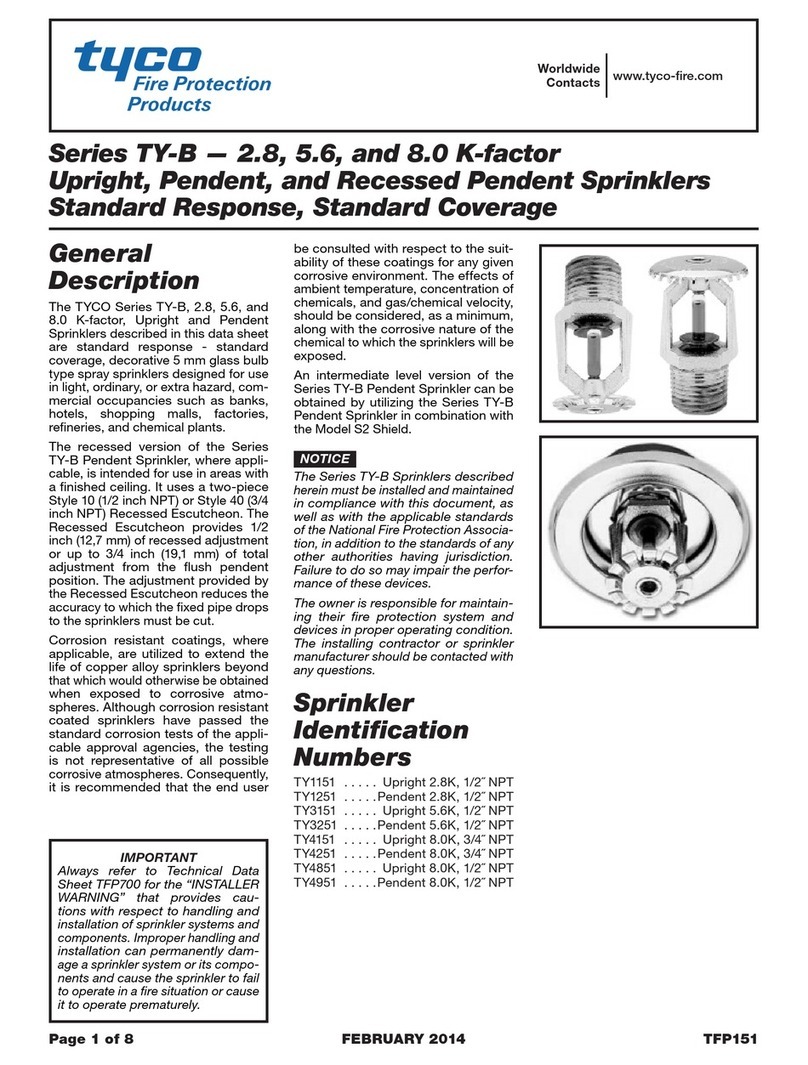

Sprinkler

Identification

Number

SIN TY3391

Technical

Data

Approvals

UL and C-UL Listed for light and ordi-

nary hazard occupancies.(Refer to the

Design Criteria section.)

NYC under MEA 351-01-E.

Maximum Working Pressure

175 psi (12,1 bar)

Inlet Thread Connection

1/2 inch NPT

Discharge Coefficient

K=5.6GPM/psi

1/2

(80,6 LPM/bar1/2)

Temperature Ratings

135°F/57°C, 155°F/68°C, 175°F/79°C,

or 200°F/93°C

Finishes

Sprinkler: Chrome Plated

Escutcheon: Chrome Plated

Physical Characteristics

Body.............. Brass

Deflector............Bronze

DeflectorHood ........Bronze

DeflectorPost.........Bronze

Deflector Post Pin . . . . . . Bronze

DeflectorCore ........Bronze

Compression Screw . . . . . Bronze

Lever . . . . . . . . . . . . . Bronze

ReleaseSpring ........Bronze

SealingAssembly...........

. . . . . . Beryllium Nickel w/ Teflon*

BulbInsert ..........Bronze

Bulb .............. Glass

Dust Cover . . Chrome Plated Steel

Patents

U.S.A. Patent No. 6,123,153 may be

applicable to the Model TFP MAX In-

stitutional Pendent Sprinklers.

Operation

In the standby condition, the design of

the Model TFP MAX is such that a

suspended load of 75 lbs. (34 kg) or

more applied to the linkage mecha-

nism will release the sprinkler. Also,

when properly installed, the escutch-

eon is held fast to the wall to deter its

removal. The shape of the escutcheon

cannot be easily grasped, which fur-

ther deters tampering.

A glass bulb operating element is pro-

tected within the linkage mechanism of

the Model TFP MAX.The bulb contains

a fluid that expands when exposed to

heat. When the rated temperature is

reached, the fluid expands sufficiently

to shatter the glass bulb. Shattering of

the glass bulb releases the linkage

mechanism that holds the sprinkler

closed, allowing the deflector to extend

outward and water to flow.

Design

Criteria

The 5.6 K-factor, Model TFP MAX (SIN

TY3391) Institutional Horizontal Side-

wall Sprinklers are intended for use

with fire protection systems designed

in accordance with the standard instal-

lation rules recognized by the applica-

ble Listing or Approval agency (e.g.,

UL Listing is based on NFPA 13 re-

quirements). The TFP MAX (SIN

TY3391) must be installed with a de-

flector to ceiling of 4 to 12 inches (100

to 300 mm). To meet this requirement

Model TFP MAX — 5.6 K-factor

Institutional Horizontal Sidewall Sprinklers

Quick Response, Standard Coverage

Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500

Page 1 of 4 TFP656

FEBRUARY, 2002

Customer Service/Sales:

Tel: (414) 570-5000 / (800) 558-5236

Fax: (414) 570-5010 / (800) 877-1295

TFP656 (TD575H)