Page 1 of 4 APRIL 2022 TFP321

Worldwide

Contacts

www.tyco-fire.com

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and instal-

lation of sprinkler systems and com-

ponents. Improper handling and

installation can permanently damage

a sprinkler system or its compo-

nents and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

Scan the QR code or enter the URL

in a web browser to access the most

up-to-date electronic version of this

document. Data rates may apply.

docs.jci.com/tycofire/model-

esfr-22_4-k-pen-early-sup-fast-res

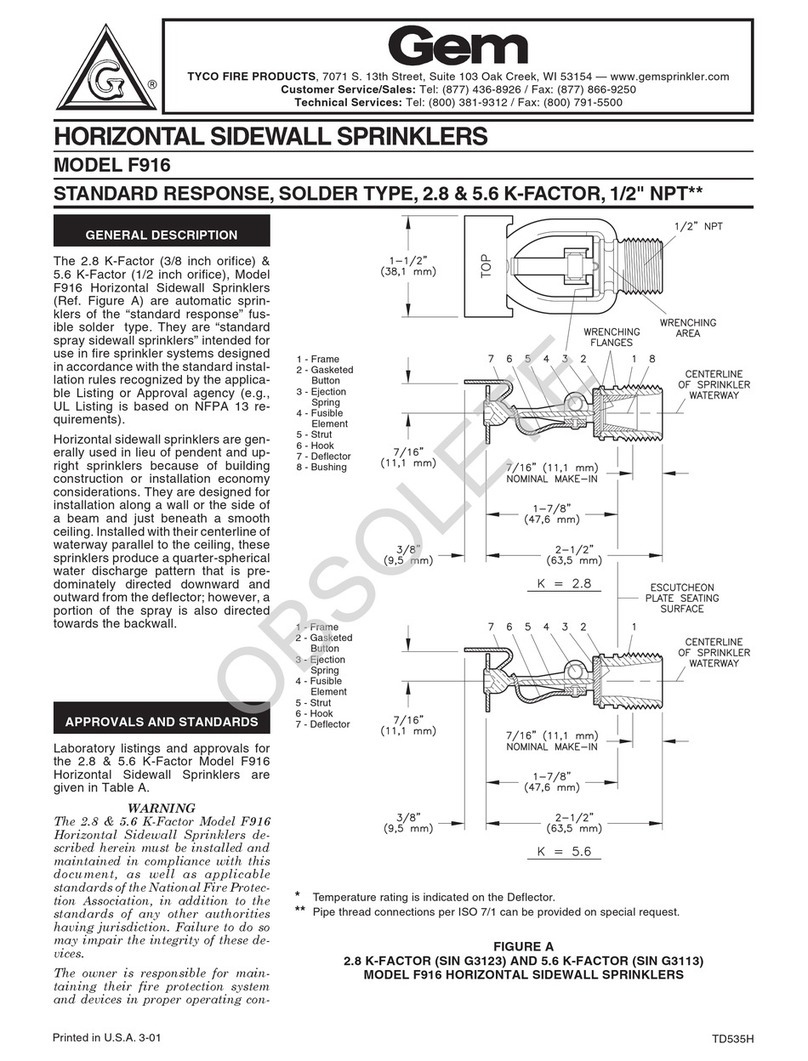

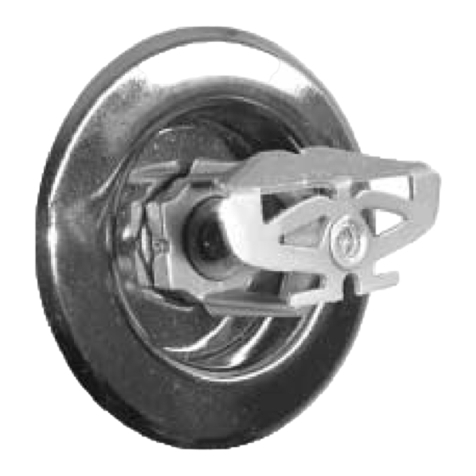

Model ESFR-22

22.4 K-factor Pendent Sprinklers

Early Suppression, Fast Response

Sprinkler

Identification

Number

See Table A

Technical

Data

Approvals

UL and C-UL Listed

FM Approved

VdS Approved

LPCB Certified

EAC Approved

Finish

Natural Brass

Physical Characteristics

Frame � � � � � � � � � � � � � � � � � � � � � � � � � � � � �Brass

Deflector � � � � � � � � � � � � � � � � � � � � � � � � � �Bronze

Compression Screw � � � � � � � � � � Stainless Steel

Hook � � � � � � � � � � � � � � � � � � � � � � � � � � � � MONEL

Strut� � � � � � � � � � � � � � � � � � � � � � � � � � � � � MONEL

Link Assembly� � � � � � � � � � � � � � � � Solder, Nickel

Button �������������� Copper/Stainless Steel

Sealing Assembly ��Beryllium Nickel w/TEFLON

Additional Technical Data

See Table A

Operation

The fusible link assembly is com-

prised of two link halves that are joined

together by a thin layer of solder� When

the rated temperature is reached, the

solder melts and the two link halves

separate, activating the sprinkler and

flowing water�

kler protection of the following storage

applications:

• Most encapsulated or non-encap-

sulated common materials including

cartoned, unexpanded plastics

• Uncartoned (exposed) expanded

plastics in accordance with NFPA 13

and FM Global standards

• Some storage arrangements of rub-

ber tires, roll paper, flammable liq-

uids, and aerosols

Note: The sprinklers are not limited to

these storage applications.

For more specific criteria, see the Tech-

nical Data section, Table A, and the

applicable design standard�

The Model ESFR-22 Sprinklers can

eliminate the use of in-rack sprinklers

when protecting high-piled storage of

specific materials up to the following

heights:

• NFPA: 40 ft (12,2 m) with ceilings up

to 45 ft (13,7m)

• FM: 45 ft (13,7 m) with ceilings up to

50 ft (15,2 m)

For more specific criteria, see Table B

and the applicable design standard�

NOTICE

The TYCO Model ESFR-22 Sprinklers

described herein must be installed

and maintained in compliance with this

document, as well as with the applica-

ble standards of the National Fire Pro-

tection Association (NFPA), in addition

to the standards of any authorities

having jurisdiction such as FM Global.

Failure to do so may impair the perfor-

mance of these devices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. Contact the installing contrac-

tor or product manufacturer with any

questions.

In all cases, the appropriate NFPA or

FM installation standard, or other appli-

cable standard, must be referenced

to ensure applicability and to obtain

complete installation guidelines. The

general guidelines in this technical data

sheet are not intended to provide com-

plete installation criteria.

General

Description

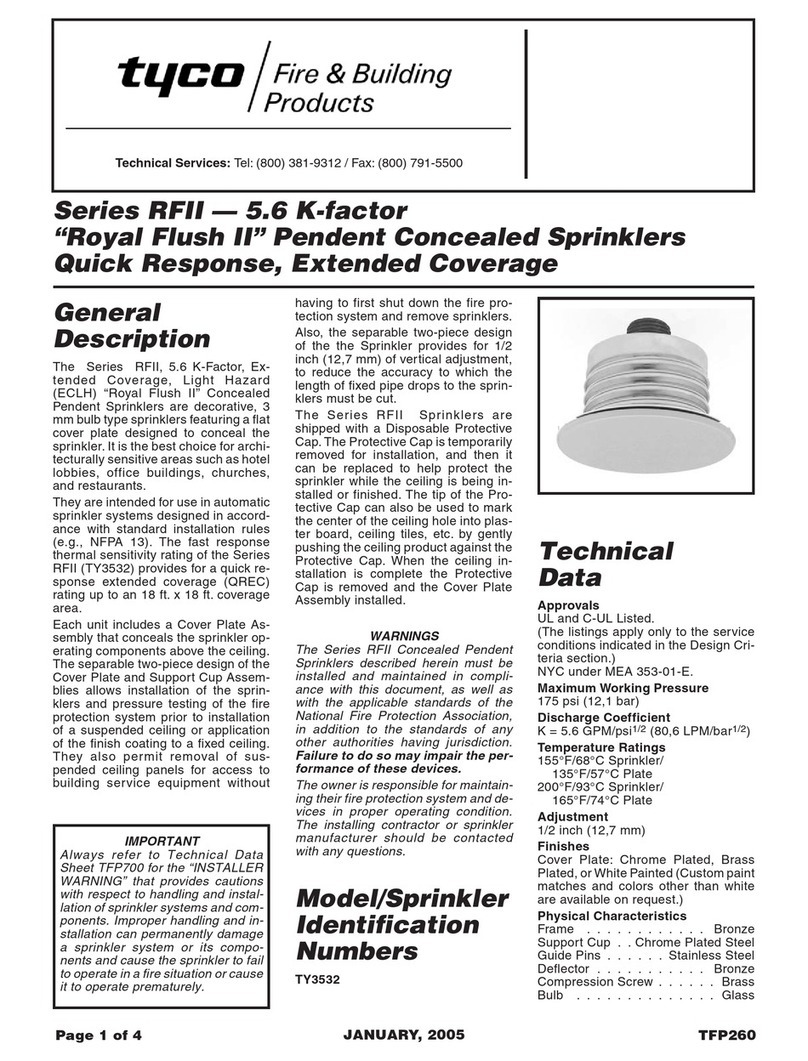

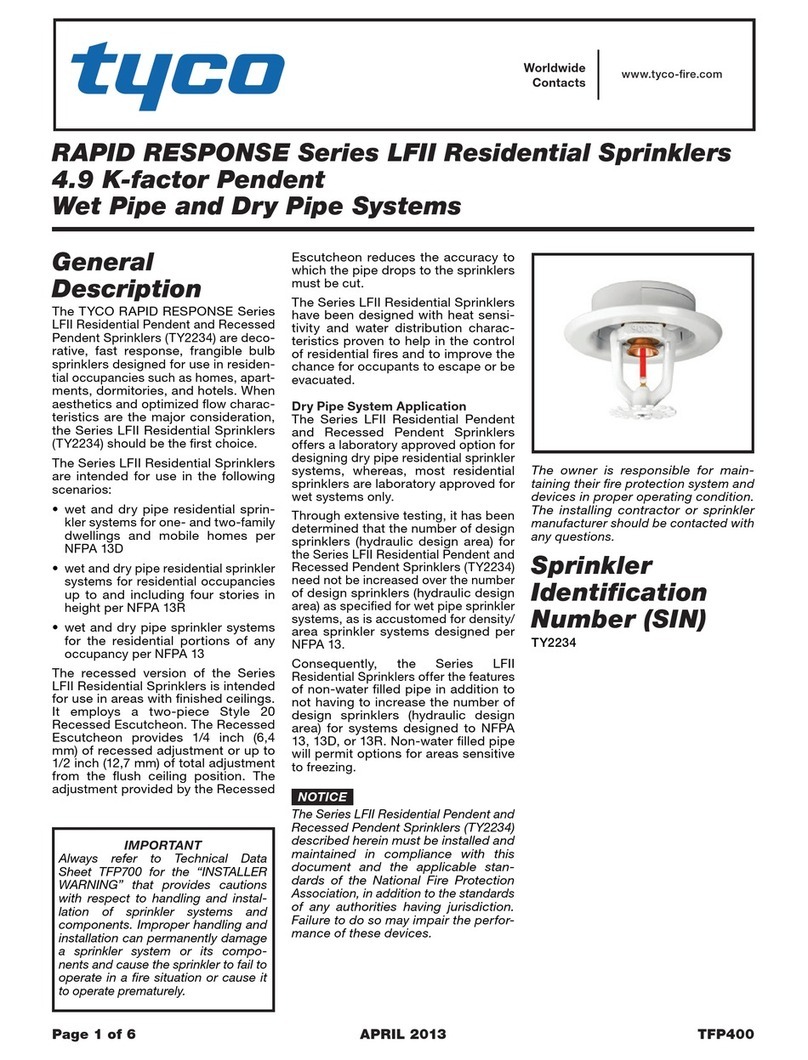

The TYCO Model ESFR-22 Pendent

Sprinklers are Early Suppression, Fast

Response (ESFR) sprinklers with a

nominal K-factor of 22�4� The sprinkler

assembly is shown in Figure 1� The

sprinklers’ suppression-mode design is

especially advantageous as a means of

eliminating the use of in-rack sprinklers

when protecting high-piled storage�

The Model ESFR-22 Sprinklers are

primarily used for ceiling-only sprin-