TFP412

Page 3 of 6

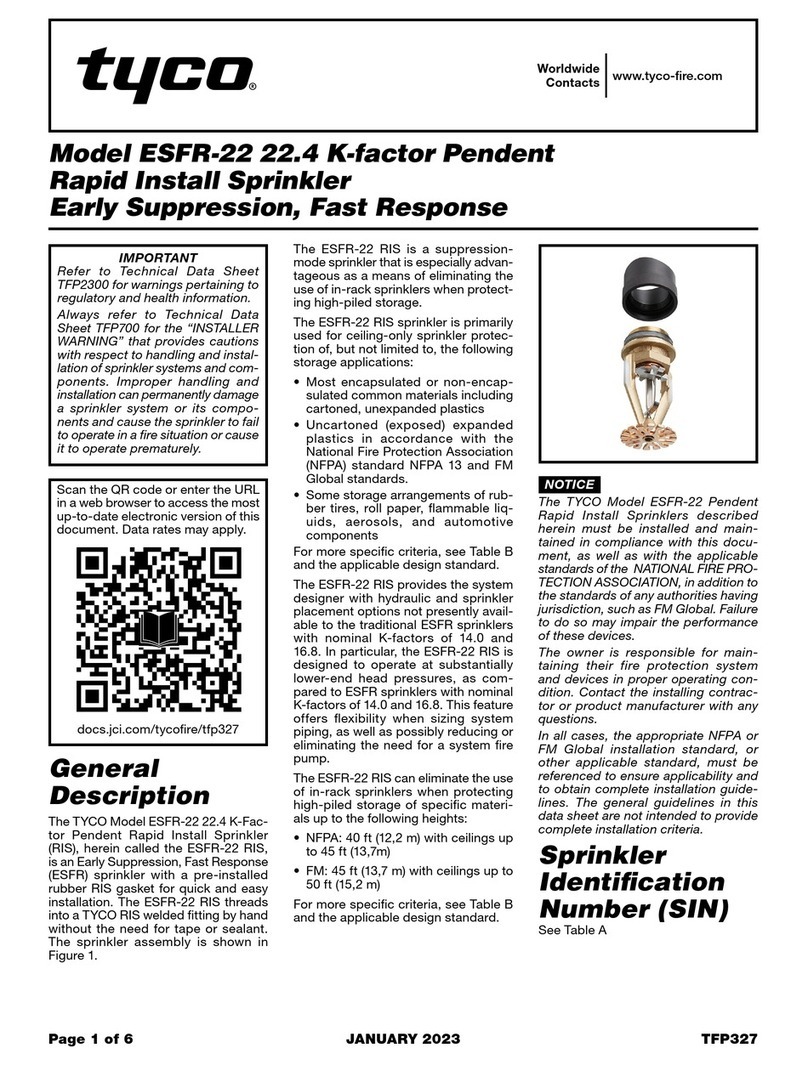

Operation

The glass bulb contains a fluid that

expands when exposed to heat. When

the rated temperature is reached, the

fluid expands sufficiently to shatter the

glass bulb allowing the sprinkler to acti-

vate and flow water.

Design

Criteria

The TYCO Series LFII (TY2334) Resi-

dential Horizontal Sidewall Sprinklers

are UL and C-UL Listed for installation

in accordance with this section.

Residential Sprinkler Design Guide

When conditions exist that are outside

the scope of the provided criteria, refer

to the Residential Sprinkler Design

Guide TFP490 for the manufactur-

er’s recommendations that may be

acceptable to the local authority having

jurisdiction.

System Type

Only wet pipe systems may be utilized.

Ceiling Type

Smooth flat horizontal, or beamed, or

sloped, in accordance with the 2013

Edition of NFPA 13D, 13R, or 13 as

applicable.

Hydraulic Design

(NFPA 13D and 13R)

For systems designed to NFPA 13D or

NFPA 13R, the minimum required sprin-

kler flow rate are given in Table A as a

function of temperature rating and the

maximum allowable coverage areas.

The sprinkler flow rate is the minimum

required discharge from each of the

total number of design sprinklers as

specified in NFPA 13D or NFPA 13R.

Hydraulic Design

(NFPA 13)

For systems designed to NFPA 13, the

number of design sprinklers is to be

the four most hydraulically demanding

sprinklers. The minimum required dis-

charge from each of the four sprinklers

is to be the greater of the following:

• The flow rates given in Table A as a

function of temperature rating and

the maximum allowable coverage

area.

• A minimum discharge of 0.1 gpm/ft2

over the “design area” comprised of

the four most hydraulically demand-

ing sprinklers for the actual cover-

age areas being protected by the

four sprinklers.

Obstruction to Water Distribution

Sprinklers are to be located in accor-

dance with the obstruction rules of

NFPA 13D, 13R, and 13 as applicable

for residential sprinklers as well as with

the obstruction criteria described within

the Technical Data Sheet TFP490.

Operational Sensitivity

The sprinklers are to be installed with

an end of defector-boss to wall dis-

tance of 1-1/8 in. to 6 in.

In addition the top-of-deflector-to-

ceiling distance is to be within the

range (see Table A) being hydraulically

calculated.

Sprinkler Spacing

The minimum spacing between sprin-

klers is 8 ft (2,4 m). The maximum

spacing between sprinklers cannot

exceed the width of the coverage area

(see Table A) being hydraulically calcu-

lated, for example, maximum 12 ft for a

12 ft x 12 ft coverage area, or 16 ft for a

16 ft x 20 ft coverage area.

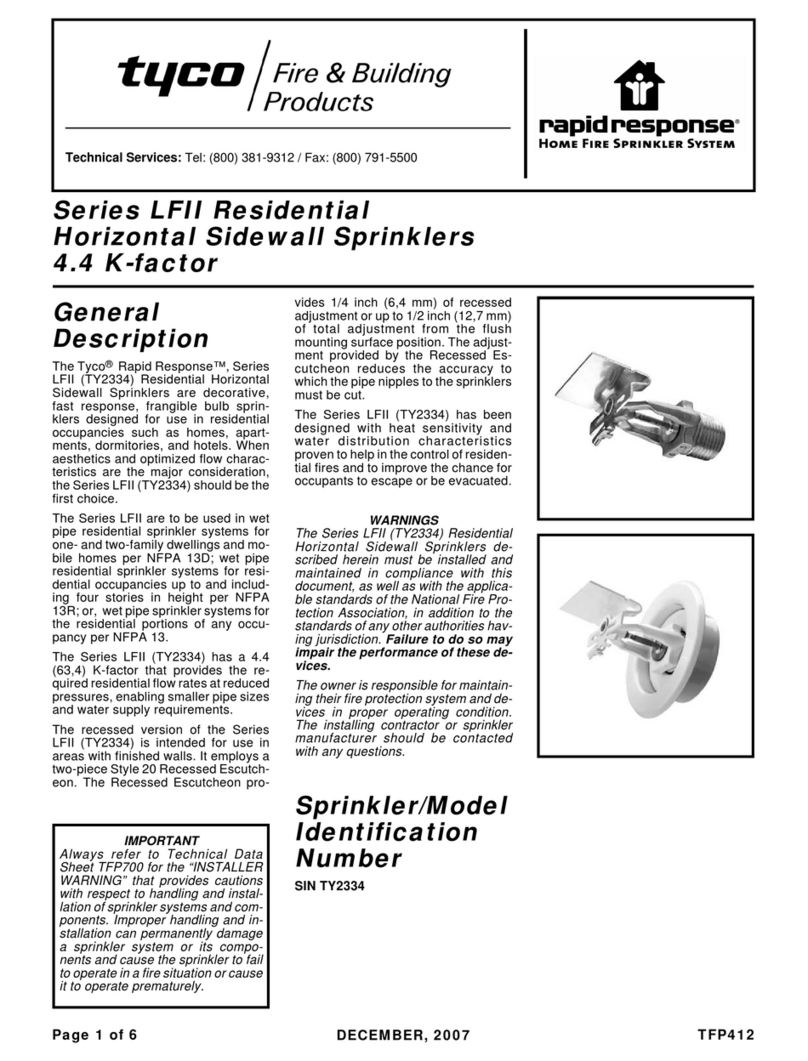

Installation

The TYCO Series LFII (TY2334) Resi-

dential Horizontal Sidewall Sprinklers

must be installed in accordance with

this section.

General Instructions

Do not install any bulb-type sprinkler

if the bulb is cracked or there is a loss

of liquid from the bulb. With the sprin-

kler held horizontally, a small air bubble

should be present. The diameter of the

air bubble is approximately 1/16 in.

(1,6 mm).

A leak-tight 1/2 in. NPT sprinkler joint

should be obtained by applying a

minimum to maximum torque of 7 to

14 lb-ft (9,5 to 19,0 N∙m). Higher levels

of torque can distort the sprinkler Inlet

with consequent leakage or impairment

of the sprinkler.

Do not attempt to compensate for

insufficient adjustment in the sprinkler

by under- or over-tightening the sprin-

kler. Re-adjust the position of the sprin-

kler fitting to suit.

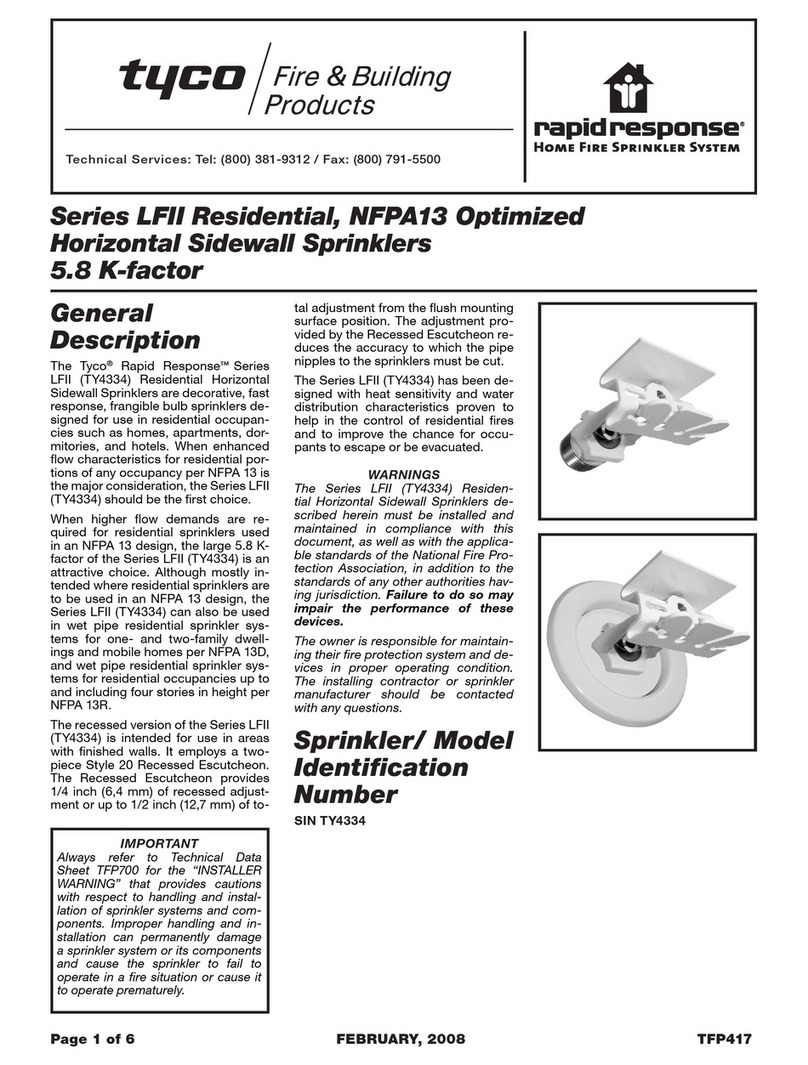

Series LFII Residential Horizontal

Sidewall Sprinklers

The Series LFII Horizontal Sidewall

Sprinklers must be installed in accor-

dance with the following instructions.

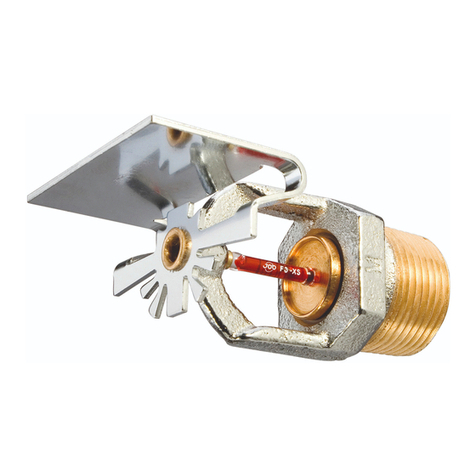

Step 1. Horizontal sidewall sprinklers

are to be installed in the horizontal

position with their centerline of water-

way perpendicular to the back wall and

parallel to the ceiling. The word “TOP”

on the Deflector is to face towards

the ceiling with the front edge of the

Deflector parallel to the ceiling.

Step 2. With pipe thread sealant

applied to the pipe threads, hand

tighten the sprinkler into the sprinkler

fitting.

Step 3. Tighten the sprinkler into

the sprinkler fitting using only the

W-Type 6 Sprinkler Wrench (see Fig-

ure 3). With reference to Figure 1, the

W-Type 6 Sprinkler Wrench is to be

applied to the wrench flats.

Series LFII Residential Recessed

Horizontal Sidewall Sprinklers

The Series LFII Recessed Horizontal

Sidewall Sprinklers must be installed

in accordance with the following

instructions.

Step A. Recessed horizontal sidewall

sprinklers are to be installed in the hor-

izontal position with their centerline of

waterway perpendicular to the back

wall and parallel to the ceiling. The

word “TOP” on the Deflector is to face

towards the ceiling.

Step B. After installing the Style 20

Mounting Plate over the sprinkler

threads and with pipe thread seal-

ant applied to the pipe threads, hand

tighten the sprinkler into the sprinkler

fitting.

Step C. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

7 Recessed Sprinkler Wrench (see Fig-

ure 4). With reference to Figure 1, the

W-Type 7 Recessed Sprinkler Wrench

is to be applied to the sprinkler wrench

flats.

Step D. After the wall has been

installed or the finish coat has been

applied, slide on the Style 20 Closure

over the Series LFII Sprinkler and push

the Closure over the Mounting Plate

until its flange comes in contact with

the wall.