PAGE 2 OF 6 0614 IH-1003

OPERATIONS

SAFETY CONSIDERATIONS

• Avoid cornering at high speed.

• Pay particular attention to other personnel as well

as fixed and moving objects within the working area

and thereby avoid accidents.

• Always pull the truck behind you if the load blocks

the view.

CAUTION! When operating on inclines, the truck

must be operated with extreme care with the

load facing downwards in the direction of the

incline. Use trucks with a hand brake.

WARNING! Braking shall take place gently and

carefully to prevent the load from slipping off

of the forks and causing damage.

CAUTION! Adapt the speed according to the

incline and surface.

• Always keep a safe distance from the edges of

loading docks and loading ramps. Be attentive to

marked risk areas.

• Before the truck is driven on to a loading ramp

ensure that the ramp is correctly secured and has

the necessary load bearing capacity. Drive slowly

and carefully across the ramp.

• When the truck is driven on to another vehicle, make

sure the vehicle is stable and that the brakes have

been applied correctly.

• Before the truck is driven into a lift, the operator must

make sure the lift is approved for the total weight

of the truck, the load, operator, and any other

passengers in the lift. When entering the lift, the load

must enter first, not the driver. No other personnel

should be in the lift when the load or truck enters or

leaves the lift.

• Any accidents that have caused personal injury

or damage to buildings or equipment must be

reported to the supervisor. Incidents and faults on

the truck shall also be reported.

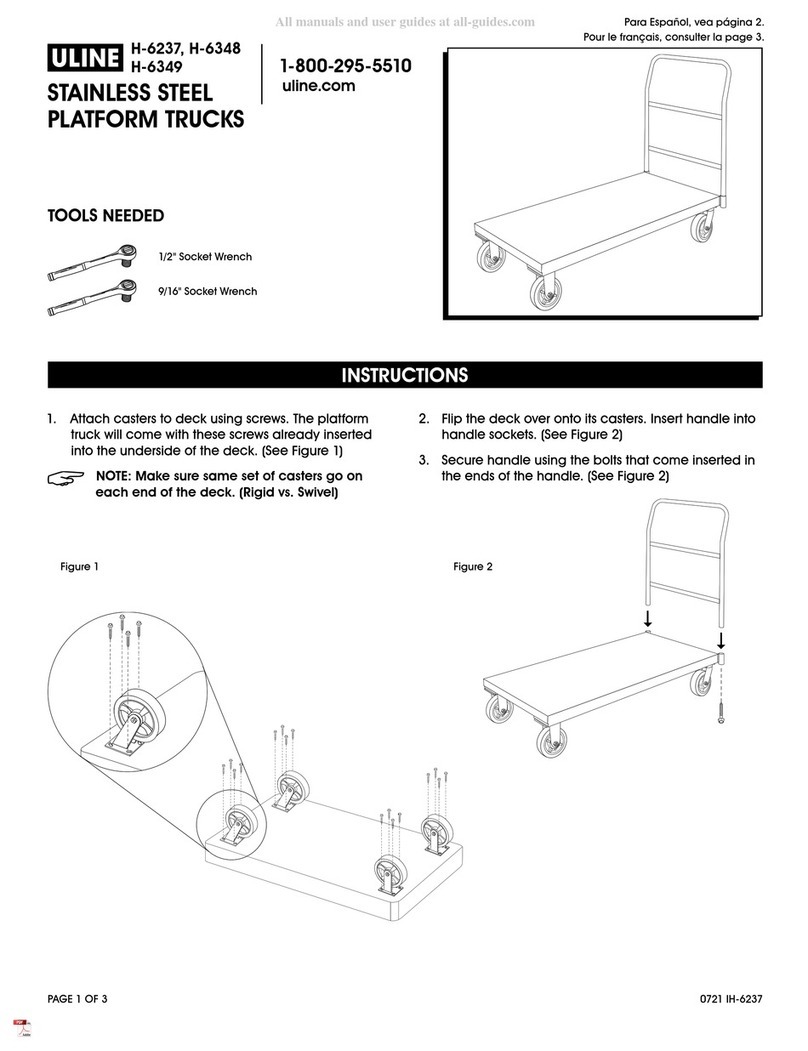

• Handling loads

• Only handle loads that are within the truck’s

permitted lifting capacity. The length and width of

the forks shall be adapted to the load’s shape and

dimensions.

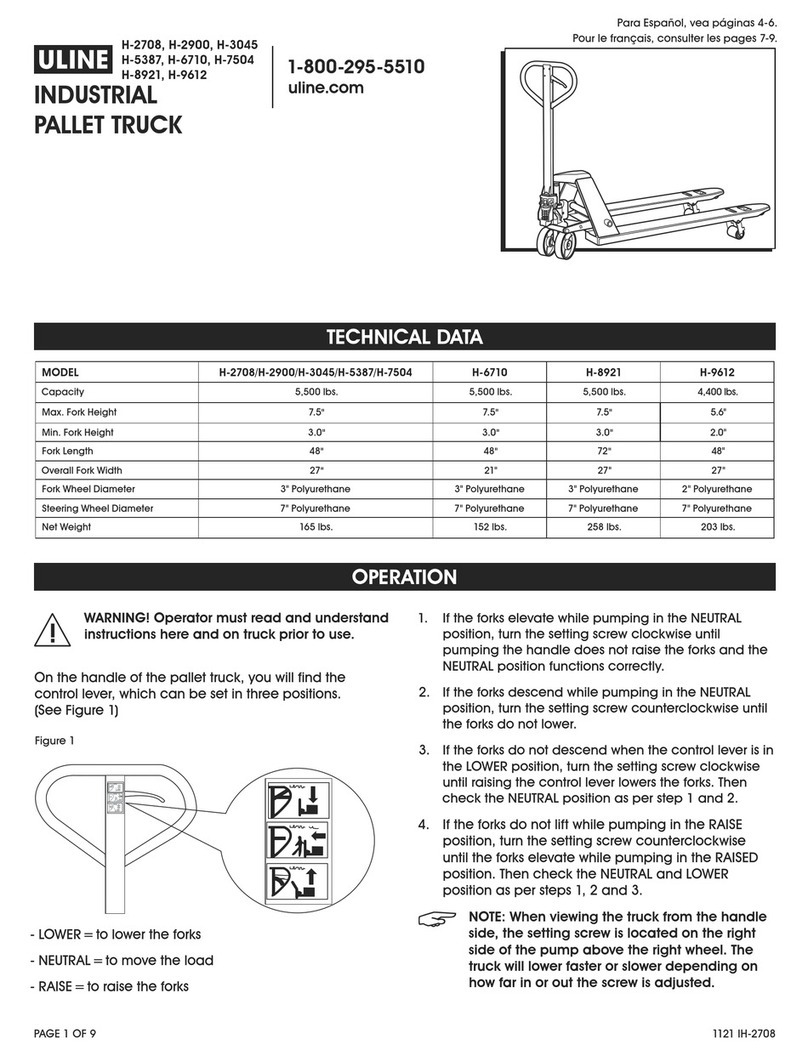

• Only loads that are stable, evenly distributed on the

forks and safely arranged should be handled.

(See Figure 1)

WARNING! Risk of overturning. Cornering: The

load can fall from the truck if the speed is too

high and cause damage. Cornering with a

high load must be performed with extreme

care.

WARNING! The truck may only be used to

carry goods. It is prohibited to use the truck to

transport persons, and as result it must not be

used as a “scooter”.

WARNING! Risk of crushing under forks. The risk

of crushing can occur when lowering or by a

defect in the hydraulic system and accidental

lowering. Be attentive to the risks of crushing

and ensure that other persons are not in the

immediate vicinity of the truck.

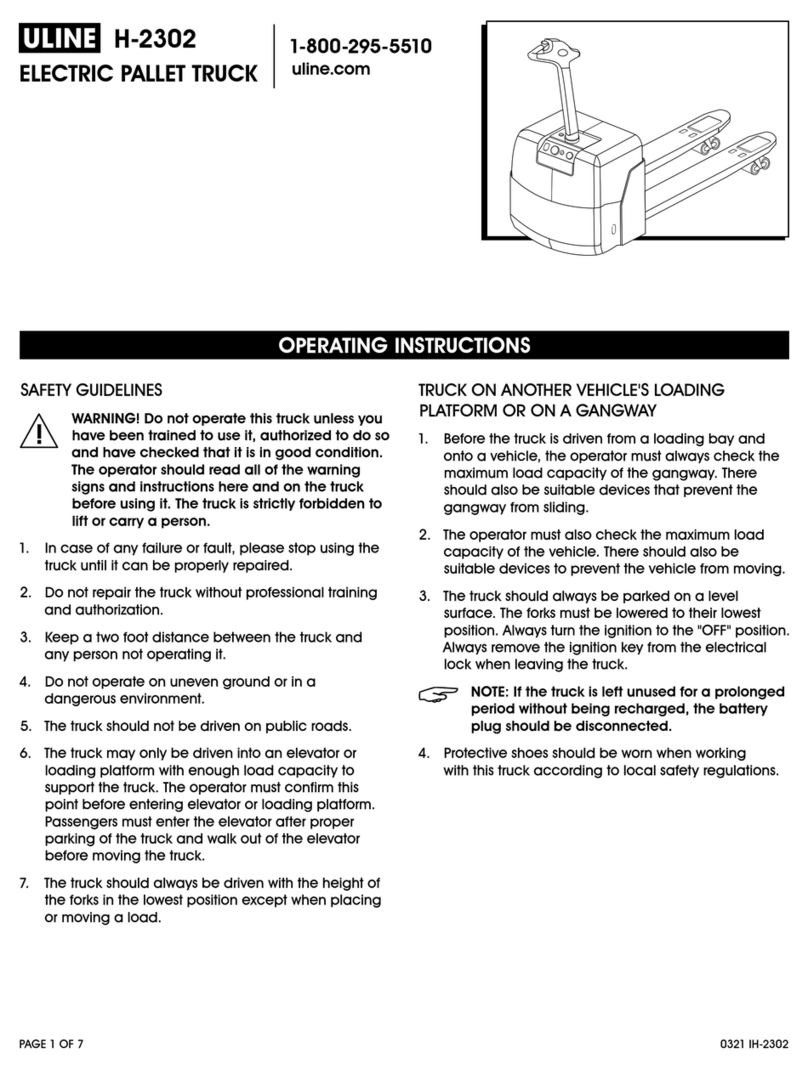

CAUTION! Risk of crushing. If the hands are

placed on the outside of the handle, there

is a risk of crushing in narrow spaces. There

is also a risk of crushing if the hands are kept

between the tow bar and the tow bar bracket,

or between the top cap and the hydraulic unit.

Because of this, be sure to keep the hands only

on the top of the handle when operating the

truck. (See Figure 2)

Figure 1