ULTRA 4002 ELECTRIC TONGUE JACK

P/N 38-944016

US PATENT 9,821,774 B1

Rev 051519

INSTALLATION/OPERATION

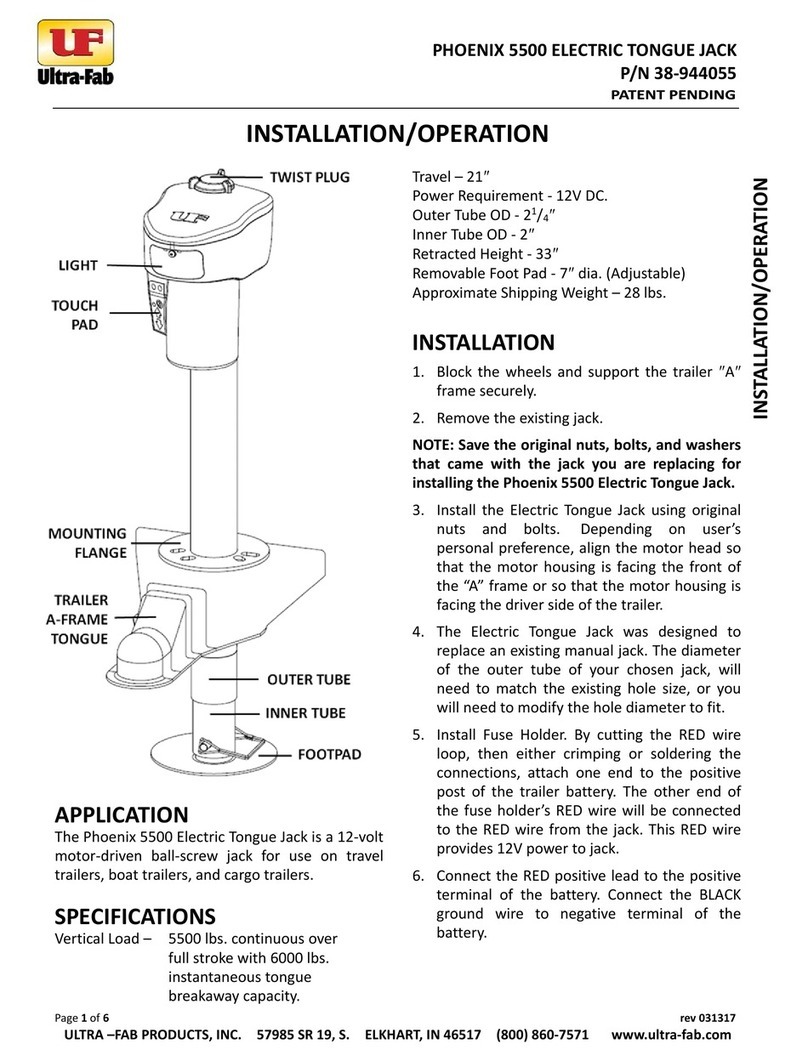

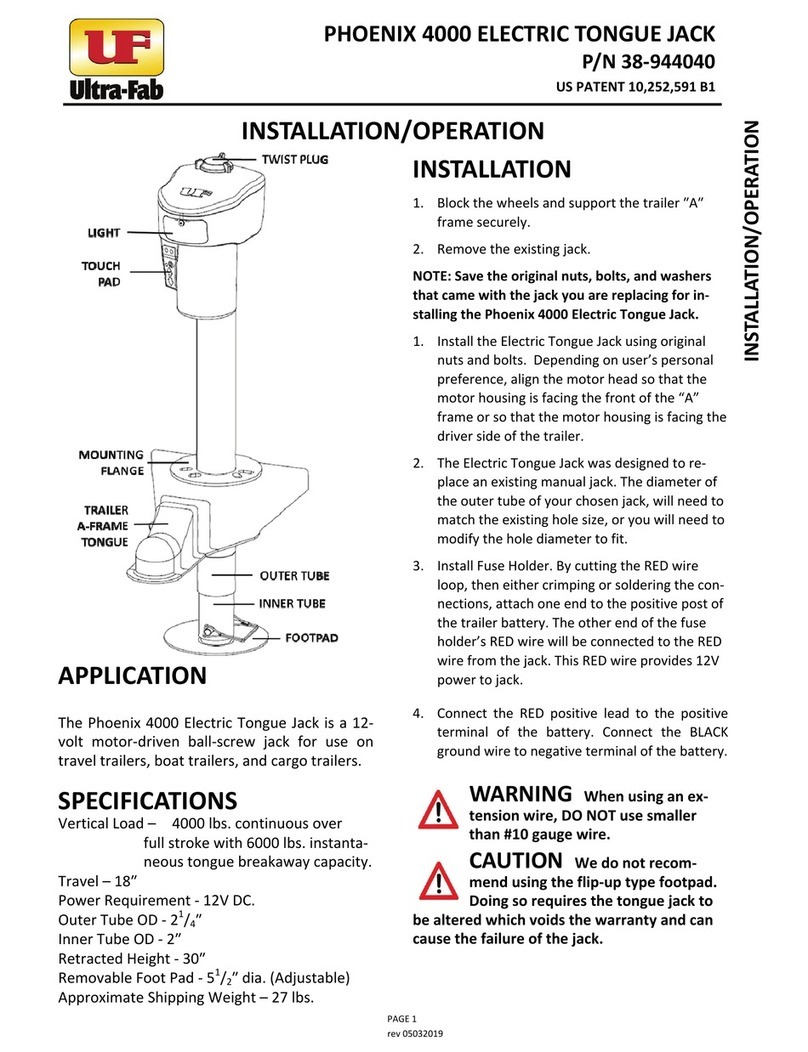

APPLICATION

The Ultra 4002 Electric Tongue Jack is a 12-volt motor-driven

screw jack for use on travel trailers, boat trailers, and cargo

trailers.

SPECIFICATIONS

Vertical Load – 4000 lbs. continuous over full stroke with 6000

lbs. instantaneous tongue breakaway capacity.

Travel – 18″

Power Requirement - 12V DC.

Outer Tube - 2″

Inner Tube – 1¾″

Retracted Height - 251/2″

Removable Foot Pad - 51/2″dia. (Adjustable)

Approximate Shipping Weight – 22 lbs.

INSTALLATION

1. Block the wheels and support the trailer ″A″frame securely.

2. Remove the existing jack.

NOTE: Save the original nuts, bolts, and washers for installing

the Ultra 4002 Electric Tongue Jack.

3. Install the Electric Tongue Jack using original nuts and

bolts. Depending on user’s personal preference, align the

motor head so that the motor housing is facing the front of

the “A” frame or so that the motor housing is facing the

driver side of the trailer.

4. The Electric Tongue Jack was designed to replace an existing

manual jack. The diameter of the outer tube of your chosen

jack, will need to match the existing hole size, or you will

need to modify the hole diameter to fit.

5. Install Fuse Holder. By cutting the red wire loop, then either

crimping or soldering the connections, attach one end to the

positive post of the trailer battery. The other end of the fuse

holder’s red wire will be connected to the red wire from the

jack. This red wire provides 12V power to jack.

6. Connect the red positive lead to the positive terminal of the

battery. Connect the black ground wire to negative terminal

of the battery.

WARNING: When using an extension wire, DO-NOT use smaller

than #10 gauge wire.

CAUTION: We do not recommend using the flip-up type

footpad. Doing so requires the tongue jack to be altered

which voids the warranty and can cause the failure of the jack.

OPERATION

1. Block trailer wheels securely.

2. The Ultra 4002 Electric Tongue Jack is operated by means of

the Motor Switch located under the motor housing.

3. Extend the jack by holding the Motor Switch in the Extend

position.

CAUTION: The motor will stall if jack reaches the full extent of

travel both in retract and extend directions. There is an over

load protection for the jack to shut off power that will auto

reset in 15 seconds. After using jack, operator should learn the

travel limit stops. The operator should stop the jack before

reaching the travel limit.

4. Retract the jack by holding the Motor Switch in the Retract

position. The jack is now fully retracted.

NOTE: If the motor should stall with the jack in the fully

retracted position, and the Motor Switch is not released, the

motor will automatically switch off.

MANUAL OPERATION

1. Disconnect the fuse. (unscrew and pull apart)

2. Remove plug cap in the access hole. (located top center of

the housing cover)

3. Insert the 9/16″socket in the access hole, over the drive hex

head. Rotate the socket clockwise to retract and counter

clockwise to extend.

4. When complete, remove socket and replace plug cap, and

reassemble the fuse connection.

LUBRICATION

The jack is lubricated before leaving the factory. Under normal

conditions, lubrication will be needed after one year.

1. Grease the jackscrew by extending the jack until the grease

fitting is aligned with the hole in the outer tube. Using

standard chassis lube grease and a standard grease gun, give

two pumps.

2. Grease the gears in gearbox.

a. Remove the fuse from fuse holder.

b. Using a 6mm Allen Wrench, remove the four socket

head screws holding the motor/gear assembly to the

top of the outer tube. Lift this assembly up and off.

Unhook the wire connections in order to have enough

slack to remove.

c. To remove the top of the gear/assembly first, remove

the motor housing (4 screws). Two of the screws that

hold the gear cover are under the motor housing.

d. Remove the gear cover (4) screws and lube gears with

chassis lube.

e. Reassemble the gear/assembly.

f. Install the gear/assembly onto the lower stem, (it is

helpful to remove the rubber plug) and look through

the main gear in order to align the flats of the main

gear in the gear/assembly with the flats of the drive

collar of the lower stem. Turn collar to align flats if

necessary.

g. Install the 6mm bolts and hook up wire connections.