HYDRAULIC CYLINDERFOROUTBOARD ENGINE -page 7 of 26

ENGLISH

InstallationandMaintenanceManual

3. Limitations. THEREPAIROR REPLACEMENT OFDEFECTIVE PARTSSHALL BE PURCHASER'SSOLE AND

EXCLUSIVEREMEDY AND UFLEX USA,INC,'SSOLEANDEXCLUSIVE LIABILITYUNDER THISWARRANTY.

LABOR FOR REPLACEMENT IS NOT INCLUDED. UFLEX USA, Inc.'s obligationunderthis warrantyis limited

totherepairorreplacement(at UFLEX USA, Inc.'s soleelection)ofanycovereditemfoundtobedefective,

whendeliveredby Purchaserpursuanttowrittenauthorizationandinstructionsfrom UFLEX USA, Inc.,

shippingprepaidto UFLEX USA,Inc.'s plantorotherdesignatedrepairfacility.Repairedorreplaced

itemsarewarrantedasprovidedhereinfortheunexpiredportionoftheapplicablewarrantyperiod.

THISWARRANTY, AND THERIGHTSAND REMEDIESUNDER IT, IS EXCLUSIVE AND IS GIVEN INPLACE OF

ALLOTHERWARRANTIES,WHETHEREXPRESSORIMPLIED,INCLUDINGANYIMPLIEDWARRANTYOF

MERCHANTABILITYOR FITNESSFORPARTICULARPURPOSE, WHETHERARISINGBYLAW,CUSTOM,

CONDUCT OR USAGE OFTRADE, PURCHASER'SREMEDIESSHALL BE LIMITED ASSTATED HEREINAND

UFLEX USA, INC. SHALL NOT BE LIABLE FOR ANY INCIDENTAL, CONSEQUENTIAL OR INDIRECT DAMAGES

ORLOSSESRESULTINGFROMDEFECTS.THERETAILSELLERIS NOTACO-WARRANTORAND ISNOT

AUTHORIZED BY UFLEX USA, INC. TO AMEND OR MODIFYTHISLIMITED WARRANTY INANY MANNER.

4.TransferabilityofWarranty. Thislimitedwarrantymay notbetransferredtosubsequentpurchasers.

5.Miscellaneous. UFLEX USA,Inc. is anaffiliateof UFLEX S.p.A. UFLEX,USA,Inc.,reservestherighttomake

changes inthedesignandconstructionofitsproducts atanytime, withoutnotice andwithoutanyobligation

toincorporatesuchchanges intoproductsofpriormanufacture. Thislimitedwarrantyapplies tonew

componentssold by UFLEX USA,Inc.. This limitedwarrantycontainstheentireagreementsbetween

UFLEX USA, Inc.andPurchaserandsuspersedes allprioragreements,discussions, negotiations,

commitmentsandrepresentations, whetheroralorwritten,betweenthemregarding UFLEX USA, Inc's

warranty.If anyprovisionofthislimitedwarranty, ortheapplicationofit,isdeterminedtobeinvalidof

unenforceableforanyreason,theremainderofthislimitedwarrantyandtheapplicationofitshallnot

beaffected.

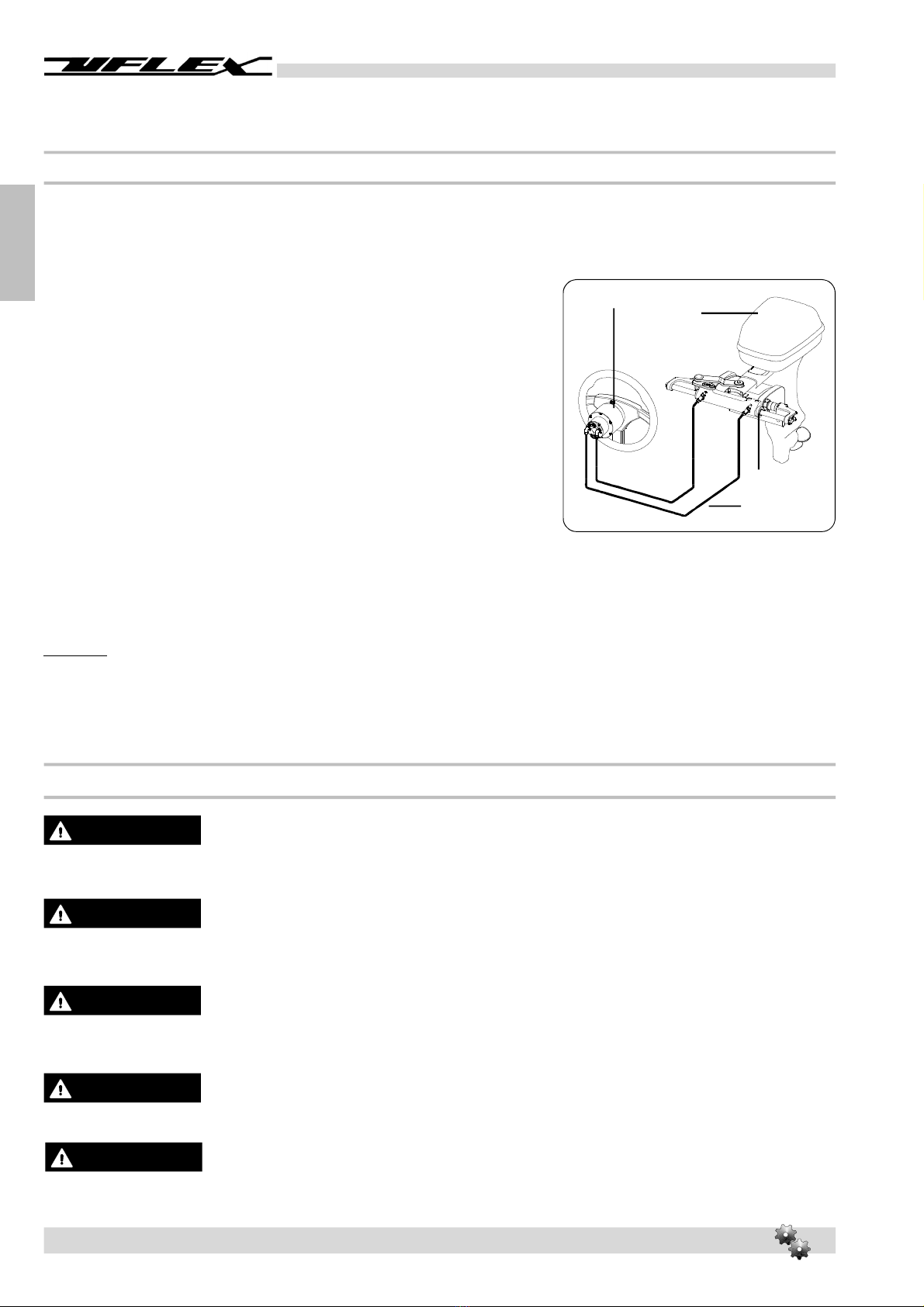

6. Ultron3000 andPowerC. TheUltron3000and"PowerC-UserandInstallationManual" describes

activities,operations,technical specificationswhichmustbefollowedduringtheinstallationand/or

usageoftheproduct,inordertokeepavalidwarranty.Descriptionsanddrawingsinthatmanualare

suitabletoallowinstallationanduse oftheproducttoskilledpersons. Incaseofdoubtand/orforany

information,pleasecontactourTechnicalService.

All communicationsandnoticesfromPurchaserregardingthis limitedwarrantyshould besentto: UFLEX

USA, INC., 6442 ParklandDrive, Sarasota, FL34243; (941)351-2628.

Return policy

Anyproductthatis presumeddefective shouldbereportedto UFLEX USAwithin48 hoursofreceiptor

discoveryinthefield.Uponnotification UFLEX USAwill attempttotroubleshoottheproblemwithourcustomer

overthephone.If weareunabletoresolvetheproblem UFLEX willissueaReturnGoodsAuthorization

numberandwerequirethattheproductinquestionbereturnedto UFLEX withallitspartsinitsoriginal

packaging.Theproductshouldbereturnedfreightprepaidto:

UFLEXUSA

RGA Department-RGA #

6442ParklandDrive

Sarasota, Florida34243

Uponreceipt UFLEX will examinetheproducttodeterminethecause ofthedefect.If theproductis determined

tohaveadefectinworkmanshipormaterial,itwillberepairedatourdiscretion.

Ourwarrantydoes notcoverlabor,towingorotherexpenses. Further,itdoes notcoverproductsthathave

beenimproperly installed,damagedininstallation,misapplied,ormisused.

Ourproductsarenotintendedforuseinracingapplications.