5TA2

• One power supply with PCO lamp installed

• Four self tapping screws (for mounting)

• Two wire nuts (used with 24V units only)

• 24v power cord or 120v power cord depending

on model

• UVC warning label

• Replacement lamp log sheet

• Large square mounting gasket

• Warranty card

• Four self-tapping screws

• Two self-tapping lamp screws

• One light shield

• One magnet with mounting screw

• One lamp mounting plate

• One lamp mounting gasket

• One 12” or 17” UVC T3 germicidal lamp

• One lamp cord w/connector

• One “Y” connector

Safety Precautions:

It is recommended that this unit be installed and maintained by a trained technician.

WARNING: UV Hazard. Always protect eyes from ultraviolet light. NEVER look at UV

lamps in operation. Unplug or disconnect power before re-lamping or servicing.

WARNING: Severe eye damage or temporary blindness may occur.

WARNING: DO NOT operate outside of air handler. Mount product in preferred

location rst.

WARNING: No openings should be allowed which would give direct line-of-sight to the UV

light.

Note: In the event of accidental breakage or replacement of the ultraviolet lamp, please

ensure that the lamp is disposed of in accordance with local and state environmental laws

regarding uorescent lamps containing mercury.

Notice:

All wiring inside of the air handler in direct line of site of the UV lamp must be shielded with

aluminum foil tape or equivalent non-combustible material. When installing this unit, select

a mounting location that prevents ultraviolet light exposure to synthetic or other plastic com-

ponents with unknown resistance to ultraviolet light. Ultraviolet light may cause color shi

or structural degradation of plastic internal components.

Maintenance:

Typical maintenance of the Air Purifying System is recommended replacement of the UVC

lamp every year.

UV lamps undergo a photochemical process during operation. is slowly reduces the

amount of UV light generated to disinfect against airborne pathogens.

Note: For the Signature Series models you must reset the service indicator light aer each

lamp replacement. with the power on press and hold the RESET button for 10 seconds using

a non-metallic implement. e LED should turn blue while the button is depressed. Release

the RESET button, and the LED should remain blue.

Important:

When installing new lamps, ensure that the lamp glass is free from any ngerprints or debris,

as this may alter the path of the UV energy. Use rubbing alcohol and a dry cloth to remove

any surface contaminants.

Replacement Lamp Log Sheet:

Included with the product is a replacement lamp log sheet. It is provided as a label so it can

be attached near the installation to ensure lamp replacements are being tracked.

Replacement Lamp Part Numbers:

UVPhotoMax System............................12” Dual Spectrum Lamp ......................AS-IH-1013

UVCatalyst System..............................12” UVC T3 germicidal Lamp..................AS-IH-1001

Replacement lamps for Remote EZLight Option

12” UVC T3 germicidal Lamp (Provides 2 years increase HVAC eciency)...AS-IH-1001

17” UVC T3 germicidal Lamp (Provides 2 years increase HVAC eciency)...AS-IH-1003

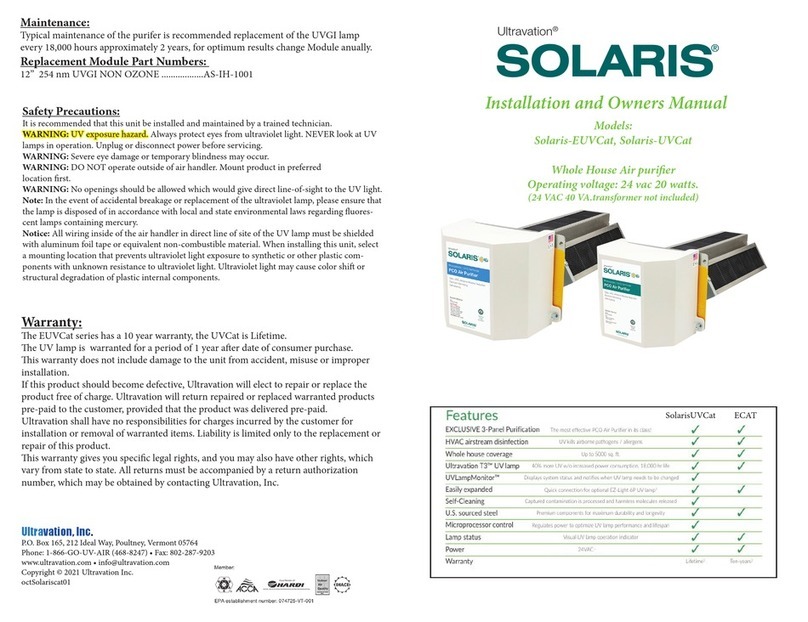

Warranty:

Ultravation® UVPhotoMAX™ and UVCatalyst oers the Ultravation ten year warranty,

Signature Series models have the Utravation lifetime warranty, with the exception of the

ultraviolet lamp(s), which are warranted for a period of one year aer date of consumer

purchase.

is warranty does not include damage to the unit from accident, misuse or improper

installation.

If this product should become defective, Ultravation will elect to repair or replace the

product free of charge. Ultravation will return repaired or replaced warranted products

pre-paid to the customer, provided that the product was delivered pre-paid.

Ultravation shall have no responsibilities for charges incurred by the customer for

installation or removal of warranted items. Liability is limited only to the replacement or

repair of this product.

is warranty gives you specic legal rights, and you may also have other rights, which vary

from state to state. All returns must be accompanied by a return authorization number,

which may be obtained by contacting Ultravation, Inc.

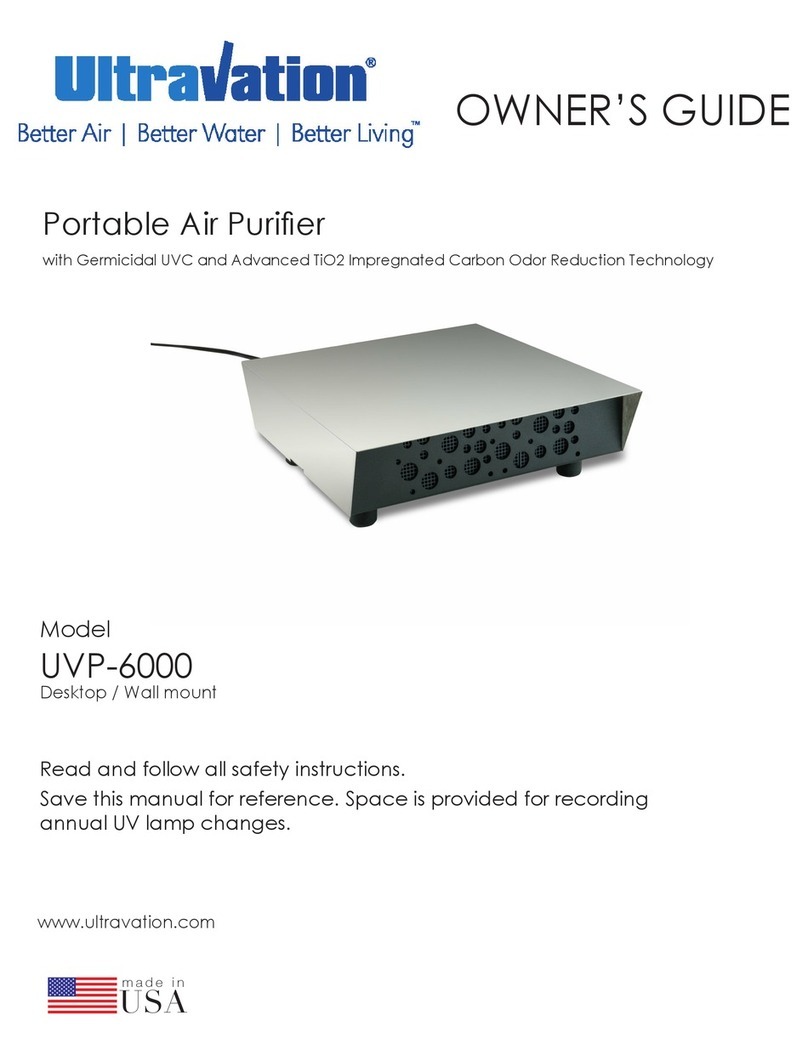

Advanced Oxidation

Air purier

Installation and Owners Manual

UVPhotomax Series

UVCatalyst Series

is manual is for the following models

Operating Operating

Model# Voltage Model# Voltage

SS-PTX-1224 24V SS-UVCatalyst-1224 24V

SS-PTX-1224-12R 24V SS-UVCatalyst-1224-12R 24V

SS-PTX-1224-17R 24V SS-UVCatalyst-1224-17R 24V

SS-PTX-1200 120-240V SS-UVCatalyst-1200 120-240V

SS-PTX-1200-12R 120-240V SS-UVCatalyst-1200-12R 120-240V

SS-PTX-1200-17R 120-240V SS-UVCatalyst-1200-17R 120-240V

PTE-1224 24V UVCatalyst-1224 24V

PTE-1224-12R 24V UVCatalyst-1224-12R 24V

PTE-1224-17R 24V UVCatalyst-1224-17R 24V

PTE-1200 120-240V UVCatalyst-1200 120-240V

PTE-1200-12R 120-240V UVCatalyst-1200-12R 120-240V

PTE-1200-17R 120-240V UVCatalyst-1200-17R 120-240V

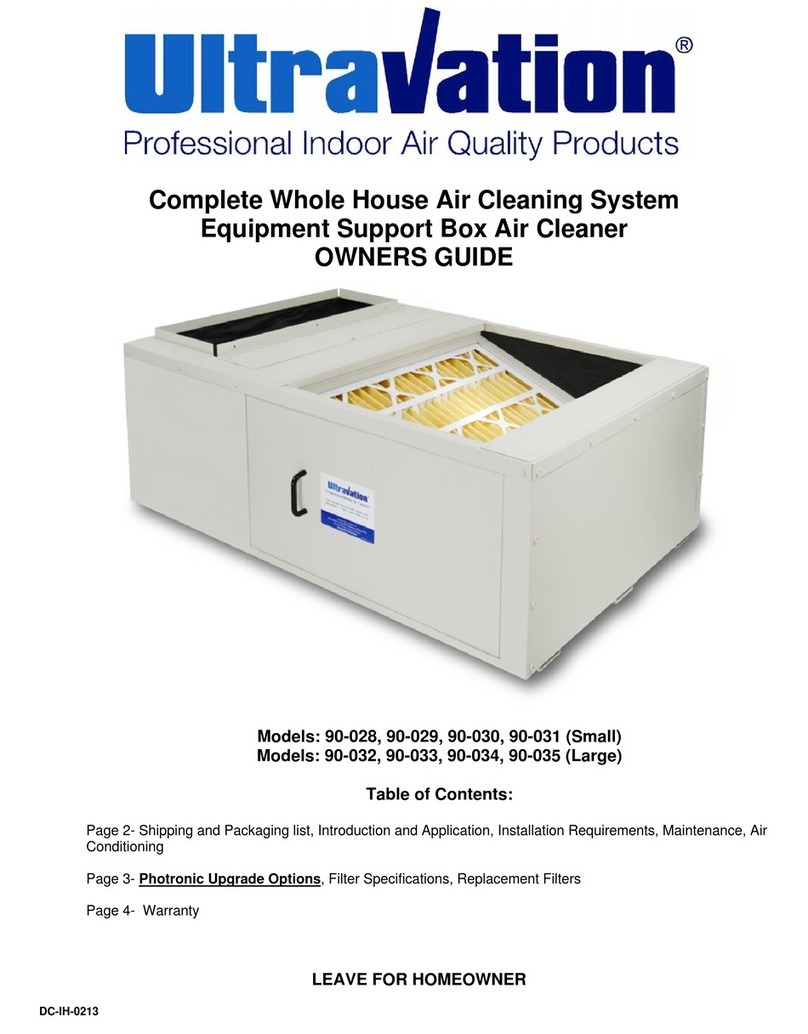

Whole House Air Cleaning

Right

Angle

Straight-

rough

Support

Box Style

To further enhance your indoor air quality try an

Ultravation ProgressiveMedia Air Cleaner with your

Advanced Oxidtion Air Purier. We manufacture the

lter frames that house our Progressive Media lters

to the same quality standards as our high

performance lter media. Built with 100% U.S origin,

galvanized steel and powder coat nish, we back all of

our ltration equipment with a ten year waranty.

For more information on Progressive

Media Whole House Air Cleaners go to:

www.ultravation.com

Signature Series

models shown