2

Safety Instructions

Electrical

Connect to a 220 - 240 VAC fully earthed supply via a 3 pin plug. It can be

dangerous to operate an ultrasonic bath without an earth connected.

The mains plug is fitted with a 5A fuse. NEVER FIT A FUSE OF A HIGHER

RATING. Some baths are fitted with a detachable mains lead. These baths have a

mains socket on the rear of the bath fitted with two 20mm fuses. See rating

information on page 14.

Ensure that excess mains cable is stored neatly.

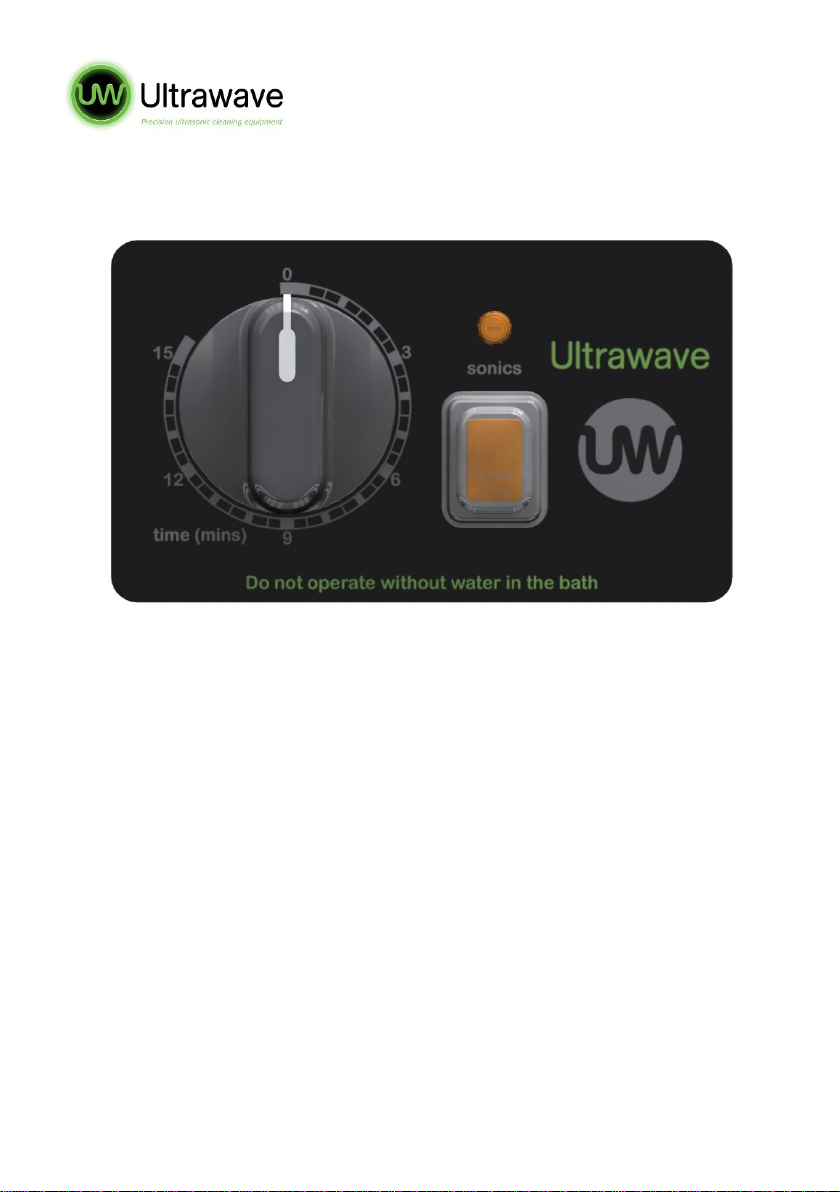

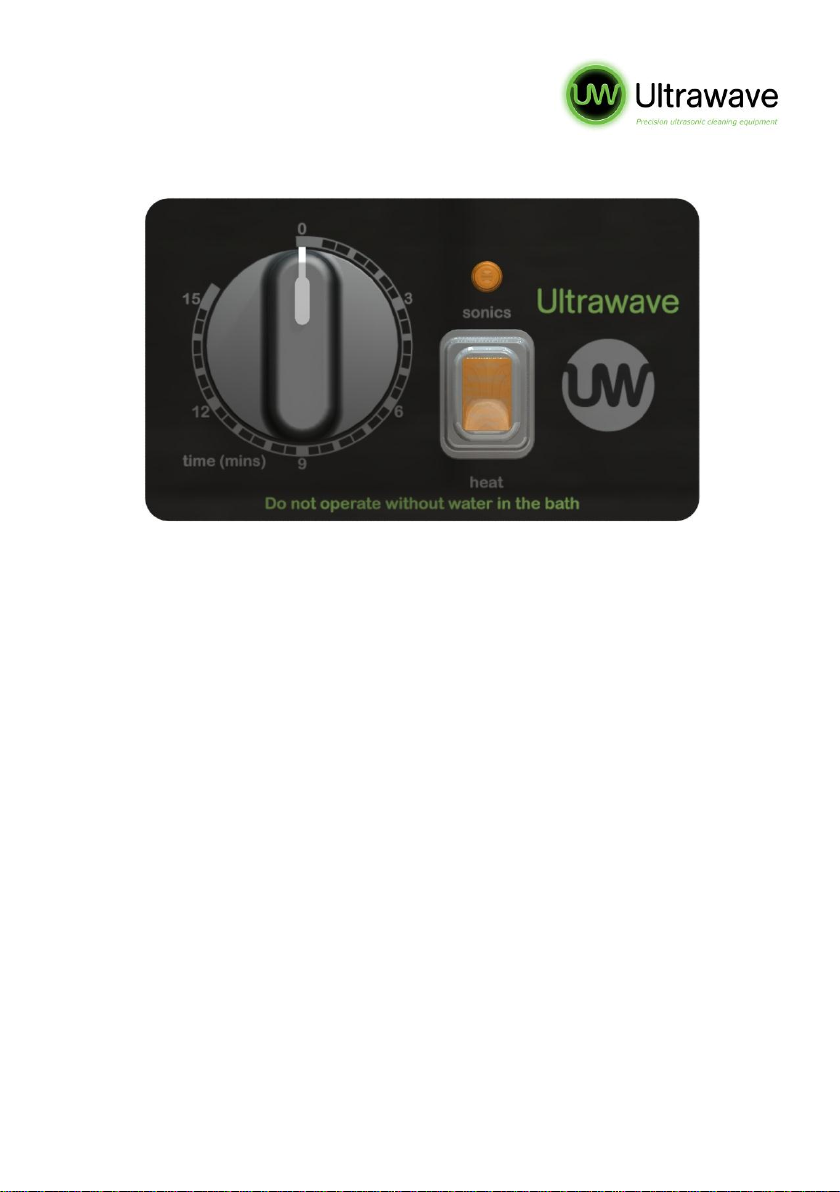

General Use

Ensure that the bath is at least ¾ full of liquid before you switch it on.

Always use a basket to support items to be cleaned. Not doing so may damage the

bath and invalidate the warranty.

Do not place hands or fingers in the bath.

Care should be taken when operating the bath at higher temperatures as

external surfaces may become hot.

Never use toxic, flammable, acidic, caustic or corrosive solutions in the

bath.

Where the bath is fitted with a detachable mains lead disconnect the bath from the

mains supply before emptying. When emptying baths with no waste outlet, tip the

bath AWAY from the electrical connector and lead.

The user should familiarise themselves with this Operator Instruction manual before

operating the equipment and should apply to Ultrawave or its agent for advice on

cleaning techniques and detergents. Ultrawave will not be responsible for damage

or injury caused by incorrect use of the equipment.

WEEE Compliance

Ultrawave are complying with the WEEE regulations by contracting-out our

obligations to a Producer Compliance scheme. Once it is deemed that this

model is no longer effective, please contact Ultrawave to arrange collection

by our compliance scheme provider, who will pick up the machine from

your premises.