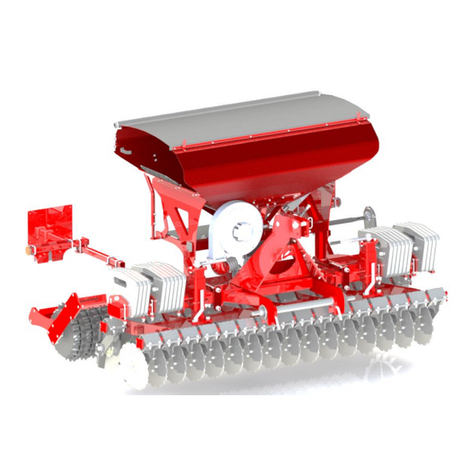

Sowing Machine AMBER 900/3

8

OPERATION OF THE MACHINE: When the machine is operated, no one must stay

within a close distance of the machine.

•The machine must be carefully checked for its safe operation and technical

condition.

•Recommendations described in the present manual and generally effective

rules of the safety and also regulations concerning the prevention of

unfortunate accidents shall be observed.

•As the width of 3.0 is exceeded – the transport of the sowing machine on

public roads with the use of a tractor is allowable only when requirements

specified under the section 2.2 (page 5 and 6) are fulfilled.

•Before proceeding with the machine operation it is required to get acquainted

with all the machine equipment and working elements and their functionalities.

•Before using the machine make sure that there are no any outsiders (children)

near the machine. Make sure that proper field of vision is guaranteed!

•It is strictly forbidden to carry any person and tools when the machine is

operated or transported!

•Never leave driver’s seat when the machine is operated!

•Before getting off a tractor always leave the machine in a working position,

machine must be lowered, tractor engine must be switched off and keys must

be removed from the ignition switch!

•It is forbidden to stay close to the sowing machine when being operated!

•When connecting and disconnecting the machine to a tractor a special care

must be taken!

•When a suspension system is adjusted it is forbidden to stay between the

machine and a tractor.

•The machine must be transported only in a Transport Position /machine is

raised/.

•When transporting the machine the markings must be folded, raised and

protected from lowering.

•When the machine is operated and during idle movement do not stay within

the reach of markers.

•When the machine is operated and transported do not stay on the machine as

it poses danger to life and threat of being poisoned with chemicals.

•Do not exceed allowable transport or working speed.

•Machine adjustment and maintenance works can be performed only when the

machine is not operated, when a tractor engine is switched off and when the

machine is lowered and supported on the ground /working position as shown

on Figure 1/.

•When sowing seeds with chemical additives it is required to strictly comply

with safety instructions indicated by the chemicals manufacturer, use personal

protective clothes (dust-proof, air passages protective clothes).

•Before proceeding with the machine operation make sure that all the

machine mechanisms are in good technical condition.

•Use a tractor with the horse power indicated by the machine manufacturer.

•Use deadweights on front axle.

•The machine, when disconnected from a tractor, must be placed in a working

position on a hard and even surface.

•When the machine operation is completed, before disconnection from a

tractor, the machine must be placed in a working position.