4

Ceiling plate

Inner pole Outer Pole

Alignment post

Clamp bracket

(qty 2) M5x12 Machine screw

(qty 10)

Adhesive pads

(qty 2)

3mm Allen wrenchThread-cutting screw

(qty 4)

Post bracket Alignment plate

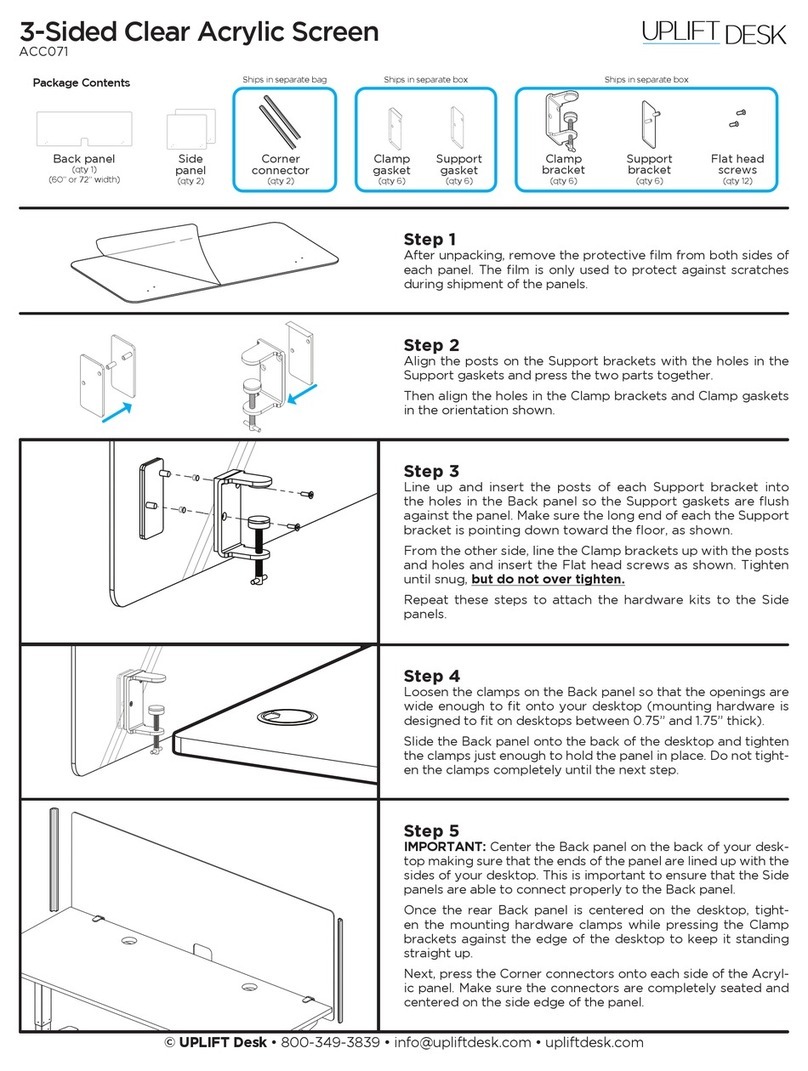

Package Contents

Step 2

Attach the Post bracket to the Outer pole in the orientation

shown here using four of the M5x12 Machine screws. Start all

four screws loosely by hand and then tighten using the 3mm

Allen wrench. Do not over tighten to avoid stripping.

Step 3

Attach the Alignment bracket to the Alignment post as shown

here using three more of the M5x12 Machine screws. Once

again, start all three screws loosely by hand before tightening

with the 3mm Allen wrench. Be careful to not over tighten.

Step 1

Begin by determining where your power and data drops will be

located. Figure out where the closest junction box in the ceil-

ing is located. The Power Pole was designed to conceal power

and data cables running from the ceiling down to the UPLIFT

Power and Data Rail when oor or wall power sources are not

available.

The Power Pole is a telescoping design that works with ceil-

ings between 8 and 12 feet high. Included with the Power Pole

assembly is a 216-inch long hardwired exible conduit power

infeed cable. Cable connections require a licensed electrician

and the length can be shortened as needed during assembly

and installation.

Power Poles attach to the Power and Data Rail square posts, so

the location of the Power Poles and power drops should be con-

sidered when designing your Power and Data Rail conguration.

One Power Pole and Power infeed cable can provide power to

up to 16 desks using four 20 amp circuits (up to four desks per

individual 20 amp circuit).

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

1

PRT00197

MAIN POLE

1

2

2

PRT00199

POWER POLE, BRACKET, ST

1

3

3 (x10)

90358A012

90358A012_METRIC STL ULTRA-

LOW-PROFILE SCKT HEAD SCREW

10

4

4

PRT00212

POWER POLE, CLAMP, ST

2

5

5 6

PRT00200

POWER POLE, LOWER TUBE, AL

1

6

PRT00207

POWER POLE, BRACKET, LOWER, ST

1

7

7

PRT00198

POWER POLE, INNER, AL

1

8

9

9 (x2)8

PRT00206

???

POWER POLE, CEILING PLT, AL

Previously unmentioned screws

1

2

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

1 2 3 (x10)4 5 67 9 (x2)8

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

1

PRT00197

MAIN POLE

1

2

2

PRT00199

POWER POLE, BRACKET, ST

1

3

3 (x10)

90358A012

90358A012_METRIC STL ULTRA-

LOW-PROFILE SCKT HEAD SCREW

10

4

4

PRT00212

POWER POLE, CLAMP, ST

2

5

5 6

PRT00200

POWER POLE, LOWER TUBE, AL

1

6

PRT00207

POWER POLE, BRACKET, LOWER, ST

1

7

7

PRT00198

POWER POLE, INNER, AL

1

8

9

9 (x2)8

PRT00206

???

POWER POLE, CEILING PLT, AL

Previously unmentioned screws

1

2

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

1 2 3 (x10)4 5 67 9 (x2)8

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

1

PRT00197

MAIN POLE

1

2

2

PRT00199

POWER POLE, BRACKET, ST

1

3

3 (x10)

90358A012

90358A012_METRIC STL ULTRA-

LOW-PROFILE SCKT HEAD SCREW

10

4

4

PRT00212

POWER POLE, CLAMP, ST

2

5

5 6

PRT00200

POWER POLE, LOWER TUBE, AL

1

6

PRT00207

POWER POLE, BRACKET, LOWER, ST

1

7

7

PRT00198

POWER POLE, INNER, AL

1

8

9

9 (x2)8

PRT00206

???

POWER POLE, CEILING PLT, AL

Previously unmentioned screws

1

2

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

1 2 3 (x10)4 5 67 9 (x2)8

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

1

PRT00197

MAIN POLE

1

2

2

PRT00199

POWER POLE, BRACKET, ST

1

3

3 (x10)

90358A012

90358A012_METRIC STL ULTRA-

LOW-PROFILE SCKT HEAD SCREW

10

4

4

PRT00212

POWER POLE, CLAMP, ST

2

5

5 6

PRT00200

POWER POLE, LOWER TUBE, AL

1

6

PRT00207

POWER POLE, BRACKET, LOWER, ST

1

7

7

PRT00198

POWER POLE, INNER, AL

1

8

9

9 (x2)8

PRT00206

???

POWER POLE, CEILING PLT, AL

Previously unmentioned screws

1

2

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

1 2 3 (x10)4 5 67 9 (x2)8

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

1

PRT00197

MAIN POLE

1

2

2

PRT00199

POWER POLE, BRACKET, ST

1

3

3 (x10)

90358A012

90358A012_METRIC STL ULTRA-

LOW-PROFILE SCKT HEAD SCREW

10

4

4

PRT00212

POWER POLE, CLAMP, ST

2

5

5 6

PRT00200

POWER POLE, LOWER TUBE, AL

1

6

PRT00207

POWER POLE, BRACKET, LOWER, ST

1

7

7

PRT00198

POWER POLE, INNER, AL

1

8

9

9 (x2)8

PRT00206

???

POWER POLE, CEILING PLT, AL

Previously unmentioned screws

1

2

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

1 2 3 (x10)4 5 67 9 (x2)8

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

1

PRT00197

MAIN POLE

1

2

2

PRT00199

POWER POLE, BRACKET, ST

1

3

3 (x10)

90358A012

90358A012_METRIC STL ULTRA-

LOW-PROFILE SCKT HEAD SCREW

10

4

4

PRT00212

POWER POLE, CLAMP, ST

2

5

5 6

PRT00200

POWER POLE, LOWER TUBE, AL

1

6

PRT00207

POWER POLE, BRACKET, LOWER, ST

1

7

7

PRT00198

POWER POLE, INNER, AL

1

8

9

9 (x2)8

PRT00206

???

POWER POLE, CEILING PLT, AL

Previously unmentioned screws

1

2

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

1 2 3 (x10)4 5 67 9 (x2)8

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

1

PRT00197

MAIN POLE

1

2

2

PRT00199

POWER POLE, BRACKET, ST

1

3

3 (x10)

90358A012

90358A012_METRIC STL ULTRA-

LOW-PROFILE SCKT HEAD SCREW

10

4

4

PRT00212

POWER POLE, CLAMP, ST

2

5

5 6

PRT00200

POWER POLE, LOWER TUBE, AL

1

6

PRT00207

POWER POLE, BRACKET, LOWER, ST

1

7

7

PRT00198

POWER POLE, INNER, AL

1

8

9

9 (x2)8

PRT00206

???

POWER POLE, CEILING PLT, AL

Previously unmentioned screws

1

2

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

1 2 3 (x10)4 5 67 9 (x2)8

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

1

PRT00197

MAIN POLE

1

2

2

PRT00199

POWER POLE, BRACKET, ST

1

3

3 (x10)

90358A012

90358A012_METRIC STL ULTRA-

LOW-PROFILE SCKT HEAD SCREW

10

4

4

PRT00212

POWER POLE, CLAMP, ST

2

5

5 6

PRT00200

POWER POLE, LOWER TUBE, AL

1

6

PRT00207

POWER POLE, BRACKET, LOWER, ST

1

7

7

PRT00198

POWER POLE, INNER, AL

1

8

9

9 (x2)8

PRT00206

???

POWER POLE, CEILING PLT, AL

Previously unmentioned screws

1

2

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

1 2 3 (x10)4 5 67 9 (x2)8

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

1

PRT00197

MAIN POLE

1

2

2

PRT00199

POWER POLE, BRACKET, ST

1

3

3 (x10)

90358A012

90358A012_METRIC STL ULTRA-

LOW-PROFILE SCKT HEAD SCREW

10

4

4

PRT00212

POWER POLE, CLAMP, ST

2

5

5 6

PRT00200

POWER POLE, LOWER TUBE, AL

1

6

PRT00207

POWER POLE, BRACKET, LOWER, ST

1

7

7

PRT00198

POWER POLE, INNER, AL

1

8

9

9 (x2)8

PRT00206

???

POWER POLE, CEILING PLT, AL

Previously unmentioned screws

1

2

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

1 2 3 (x10)4 5 67 9 (x2)8

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

Power Infeed cable

(216 in.)

C3 C4 C5

C9

H4a

H7

C6

H1 H2 H3 H5

H4b

H6

C7

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

1

PRT00197

MAIN POLE

1

2

2

PRT00199

POWER POLE, BRACKET, ST

1

3

3 (x10)

90358A012

90358A012_METRIC STL ULTRA-

LOW-PROFILE SCKT HEAD SCREW

10

4

4

PRT00212

POWER POLE, CLAMP, ST

2

5

5 6

PRT00200

POWER POLE, LOWER TUBE, AL

1

6

PRT00207

POWER POLE, BRACKET, LOWER, ST

1

7

7

PRT00198

POWER POLE, INNER, AL

1

8

9

9 (x2)8

PRT00206

???

POWER POLE, CEILING PLT, AL

Previously unmentioned screws

1

2

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

1 2 3 (x10)4 5 67 9 (x2)8

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

1

PRT00197

MAIN POLE

1

2

2

PRT00199

POWER POLE, BRACKET, ST

1

3

3 (x10)

90358A012

90358A012_METRIC STL ULTRA-

LOW-PROFILE SCKT HEAD SCREW

10

4

4

PRT00212

POWER POLE, CLAMP, ST

2

5

5 6

PRT00200

POWER POLE, LOWER TUBE, AL

1

6

PRT00207

POWER POLE, BRACKET, LOWER, ST

1

7

7

PRT00198

POWER POLE, INNER, AL

1

8

9

9 (x2)8

PRT00206

???

POWER POLE, CEILING PLT, AL

Previously unmentioned screws

1

2

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

1 2 3 (x10)4 5 67 9 (x2)8

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

1

PRT00197

MAIN POLE

1

2

2

PRT00199

POWER POLE, BRACKET, ST

1

3

3 (x10)

90358A012

90358A012_METRIC STL ULTRA-

LOW-PROFILE SCKT HEAD SCREW

10

4

4

PRT00212

POWER POLE, CLAMP, ST

2

5

5 6

PRT00200

POWER POLE, LOWER TUBE, AL

1

6

PRT00207

POWER POLE, BRACKET, LOWER, ST

1

7

7

PRT00198

POWER POLE, INNER, AL

1

8

9

9 (x2)8

PRT00206

???

POWER POLE, CEILING PLT, AL

Previously unmentioned screws

1

2

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8

1 2 3 (x10)4 5 67 9 (x2)8

1

2

3 (x2)

3 (x5)

9 (x2)

3 (x3)

4 (x2)

5

6

7

8