STORAGE

If the inverter is not put into use immediately, the storage of inverter should meet the

following requirements:

• Do not remove the outer packing.

• The inverter needs to be stored in a clean and dry place, and prevent the erosion of

dust and water vapor.

• The storage temperature should be kept at -40°C~+70°C, and the relative humidity

should be kept at 5%RH~95%RH.

• The stacking of inverters is recommended to be placed according to the number of

stacking layers in the original shipment. Place the inverter carefully during stacking to

avoid personal injury or equipment damage caused by the falling of equipment.

• Keep away from chemically corrosive substances that may corrode the inverter.

• Periodic inspections are required. If damages are found by worms and rats, or packag-

ing are found to be damaged, the packaging materials must be replaced in time.

After long-term storage, inverters need to be inspected and tested by qualified personnel

before put into use.

INSTALLATION

This chapter describes how to install the inverter and connect it to the grid-tied solar

system (including the connection between solar modules, public grid and inverter).

Read this chapter carefully and ensure all installation requirements are met before

installation. Only qualified electricians are allowed to install the inverter.

UNPACKING INSPECTION

The inverter has been thoroughly tested and rigorously checked before delivery, but

damage may still occur during transportation. Before unpacking, check carefully whether

the product information in the order is consistent with that on the nameplate of the

package box and whether the product package is intact. If any damage is detected,

please contact the shipping company or the supplier directly. Please also provide photos

of the damage to get our fastest and best service.

Store the idled inverter in its original package and take anti-moisture and anti-dust

measures.

After taking the inverter out of the box, check the following items:

(1) Confirm the main body of the inverter is intact and free from any damage;

(2) Confirm there is operation manual, interface accessories and installation accessories

inside the package box;

(3) Confirm the deliverables inside the package box are intact and complete;

(4) Check whether the product information in the order is consistent with that on the

inverter nameplate;

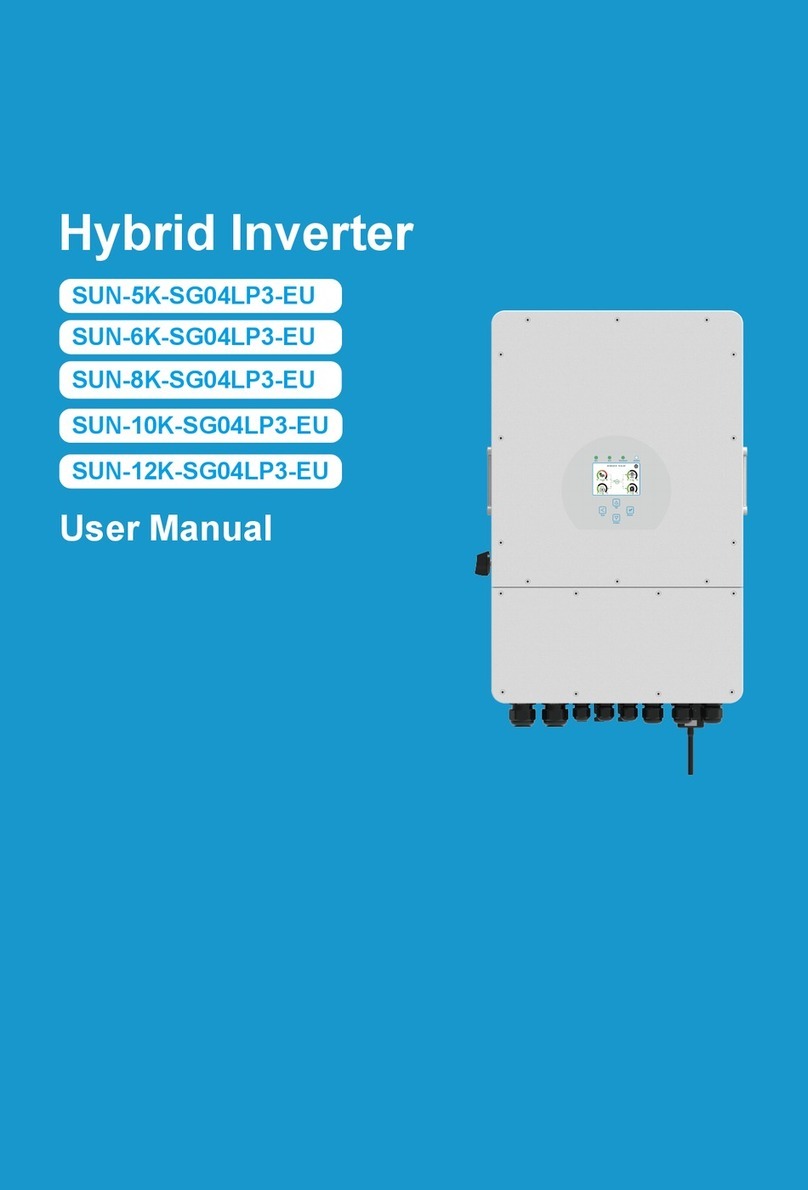

(5) The standard delivery list is shown below

Standard deliverables of inverter:

Figure 7 Delivery content