© Vaisala 2021.All rights reserved. Any logos and/or product names are trademarks of

Vaisala or its individual partners. Any reproduction, transfer, distribution or storage of

information contained in this document is strictly prohibited. All specifications —

technical included are subject to change without notice.

QUICK GUIDE

WA252 Heated Anemometer

INSTALLATION

Initial check

Before installation, check that WAA252 is not damaged during

transportation. Make sure that the shaft rotates smoothly without

any detectable noise. Vaisala recommends mounting the sensor

body when the cup assembly is removed. Be careful not to cause

damage to the shaft of the sensor body or to the connector pins.

Mounting instructions

Vaisala recommends installing the heated anemometer WAA252

onto WAC151 sensor cross arm. On bottom of WAA252 there is

a special button-shaped temperature sensor (diameter 22 mm),

elastically attached to the bottom plate. This is for sensing the

ambient temperature. Set it in good thermal contact with the

mounting support.

NOTE The three mounting screws must be properly

tightened to force the temperature sensor button

firmly enough against the support.

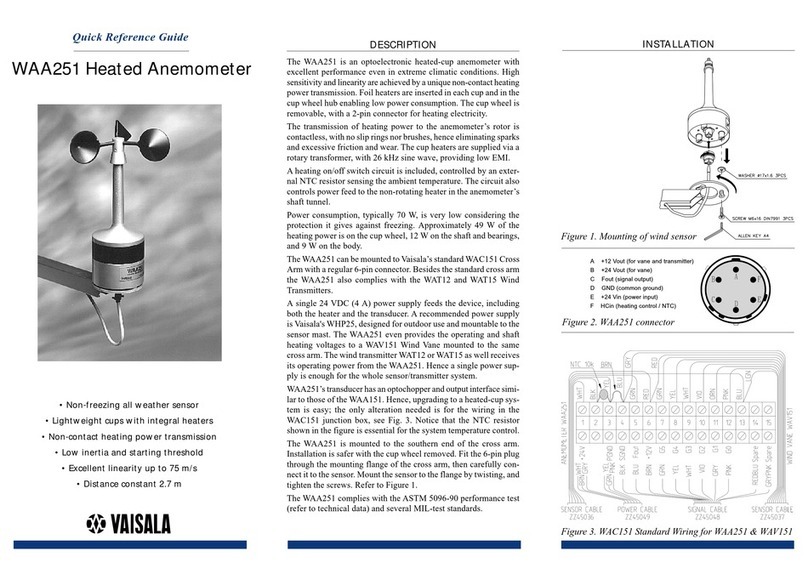

Figure 1. Mounting of the wind sensor and the hub

If you use the WAC151 cross arm, mount WAA252 at the

southern end, and WAV252 Heated Wind Vane at the northern

end.

Pre-assemble the 3 mounting screws with plastic washers

to the anemometer's mounting legs.

Fit the 6-pin cable plug through the mounting flange and

connect it to the sensor.

Mount the anemometer to the flange by twisting, and

tighten the screws.

Mount the cup assembly. Align the planes in the shaft and

inside the hub. The bottom edges of the hub and the

shoulder must reach approximately the same level (see

Figure 1). Tighten the set screw.

WAC151 wiring

The wiring diagram for the WA252 system to the WAC151 sensor

cross arm is shown in Figure 2. The power input wire connections

are highlighted, since they differ from those for regular wind

sensors.

Figure 2. WAC151 standard wiring for WAA252 and WAV252

When using standard power and signal cables ZZ45049 and

ZZ45048, the connections are following:

For power supply, connect the YEL, GRN, and PNK

wires to the screw terminal #2 and the WHT, BRN, and

GRY wires to the terminal #3.

For signal output and grounding, connect BLU to the

terminal #1 and BLK to the terminal #5.

For the optional transducer power input connect RED to

the terminal #4.

For the optional power output for external transmitter

move the REDBLU spare wire to the terminal #13.

Use Vaisala WHP25 Mains Power Supply as a power source. It

has a mast-mountable, all-weather enclosure. For a typical

installation, see cover figure. WHP25 is sold as a spare part.