10/18

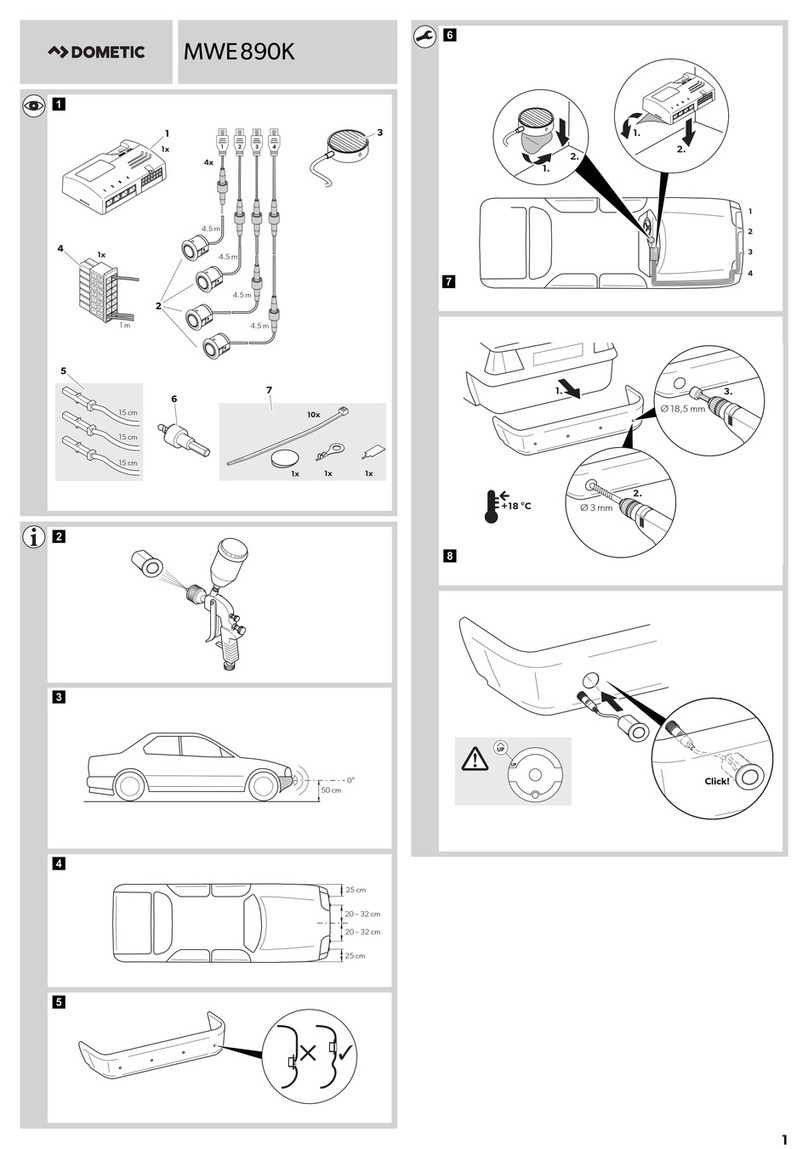

ASSEMBLY INSTRUCTIONS

Warning point adjuster 2910002025200 TU00-0761-5507150 1–3 1

Technical details subject to change

TU00-0761-5507150

EN

Safety instructions

•The product has been developed, manufactured and tested in

consideration of the basic safety requirements of EC directives

and the generally recognised engineering standard.

•The device is intended for use in non-floating vehicles and machines

as well as for pleasure crafts, including non-classified professional

navigation.

•Only use our products for the intended purpose. Personal injuries

as well as material damage or environmental damage can result if

the product is used for purposes other than those intended. Before

installation, please inform yourself on the vehicle type and any

special features on the basis of the vehicle papers.

•Use the construction plans to inform yourself of the position of fuel/

hydraulic/compressed air lines and electric cables.

•Note any changes to the vehicle that have to be taken into account

during installation.

•Basic knowledge of vehicle/ship electrical and mechanical systems

is necessary to avoid personal injuries, property damage or environ-

mental damage.

•Make sure the engine cannot be started accidentally during

installation.

•Changes or manipulation of the VDO product can have a negative

influence on safety. For this reason, it must not be changed or

manipulated.

•During the removal/installation of seats, covers etc., make sure

that you do not damage or loosen any lines, cables or plug-type

connections.

•Note all the data from other installed devices with volatile electronic

memories.

During installation, pay attention to the following:

•During installation make sure that product components do not influ-

ence or hinder the vehicle functions and do not become damaged.

•Only install non-damaged parts in the vehicle.

•During installation make sure that the field of vision is not impaired

by the product and that the product is not positioned in a location

where the driver or passenger could bang their head against it.

•You should have a specialist install the product. If you install it

yourself, wear suitable working clothes. Do not wear loose-fitting

clothing. It can become caught in moving parts. Wear a hair net

over long hair.

•Do not wear any metallic or conductive jewellery such as chains,

bracelets, rings etc. during work on the on-board electric system.

•If work is necessary on the engine while it is running, special care

must be taken. Only wear appropriate working clothes, since there

is a risk of injury through crushing and burns.

•Before starting work, disconnect the negative battery pole, since

there is a risk of short circuit otherwise. If the battery has additional

batteries, the negative poles of these batteries may also have to be

disconnected. Short circuits can cause cable fires, battery explosions

and damage to other electronic systems. Please note that all values

entered in volatile electronic memories will be lost when the batteries

are disconnected and will have to be reprogrammed.

•Before starting work in the engine room of boats powered by a petrol

engine, let the engine fan run.

•Pay attention to how cable strands are routed so as not to damage

these during drilling and sawing work.

•Do not choose the installation location in the mechanical and electric

airbag area.

•Do not drill holes or make installation openings in load-bearing or

stabilising bars or beams.

•During work under the vehicle, secure it according to the vehicle

manufacturer’s specifications.

•Make sure there is enough space behind the drilled holes or

installation opening when choosing the installation location.

Necessary installation depth is 65 mm.

•Pre-drill installation openings as small holes, then use a tapered

milling cutter, hole saw, jig saw or file to enlarge them and finish

them off. Deburr the edges. Always observe the safety instructions

provided by the tool manufacturer.

•If work is necessary without disconnecting the voltage, insulated

tools must always be used.

•Only use designated multimeters or diode test lamps for measuring

voltages and current in the vehicle/machine or ship. The use of

conventional test lamps can result in damage to the control units or

other electronic systems.

•The electric outputs of the display unit and the cables connected

must be protected from direct contact and damage. For this, the

cables used must be sufficiently insulated or have sufficient electric

strength and the contact points must be touch-proof.

•The electrically conducting parts of the consumers connected must

also be protected from direct contact by corresponding measures.

The laying of metallic bare cables and contacts is not permitted.

After installation, please pay attention to the following:

•Connect the ground cable tightly to the battery’s negative pole.

•Re-enter/reprogram the values of the volatile electronic memory.

•Check all functions.

•Only use clear water to clean the components.

Pay attention to IP protection types (IEC 60529).

Electrical connection:

•Pay attention to the cable cross-section.

•Reducing the cable cross-section leads to a higher current density.

This can lead to the respective cable section overheating.

•Use existing cable ducts and strands to lay the electric cables, but

do not lay the cables parallel to ignition cables or parallel to cables

which lead to large current consumers.

•Fix the cables using cable ties or adhesive tape. Do not route the

cables over moving parts. Do not attach the cables to the steering

column.

•Make sure that the cables are not subject to tensile, compressive

or shearing forces.

•Where the cables are routed through bore holes, protect the cables

using rubber grommets or similar.

•Only use stripping pliers for stripping the cables. Use the pliers in

such a way that no stranded wires are damaged or cut through.

•Always only use the soft-soldering method to solder any new cable

connections to be created, or use standard crimp connectors.

•Always use a cable crimping tool to make the crimped connections.

Note the safety instructions provided by the tool manufacturer.

•Insulate the exposed stranded wires in such a way that no short-

circuits can be caused.

•Caution: risk of short-circuit due to faulty connection points or

damaged cables.

•Short circuits in the vehicle electric system can cause cable fires,

battery explosions and damage to other electronic systems. For

this reason, all power supply connections must have weldable

connectors and be sufficiently insulated.

•Pay particular attention to perfect ground connections.

•Faulty connections can lead to short circuits. Only connect the

cables in accordance with the electric terminal diagram.

•When operating the device on power packs, note that the power

pack must be stabilised and comply with the following standards:

DIN EN 61000- Part 6-1 to 6-4.

No smoking permitted!

Do not use open fire or light sources!