2

Contents

VEGAFLEX 81 • Two-wire 4 … 20 mA/HART SIL

47591-EN-230605

Contents

1 For your safety ......................................................................................................................... 3

1.1 Authorised personnel ....................................................................................................... 3

1.2 Appropriate use................................................................................................................ 3

1.3 Warning about incorrect use............................................................................................. 3

1.4 General safety instructions............................................................................................... 3

1.5 Conformity........................................................................................................................ 3

1.6 SILqualicationaccordingtoIEC61508.......................................................................... 4

1.7 NAMUR recommendations .............................................................................................. 4

1.8 Environmental instructions ............................................................................................... 4

2 Product description ................................................................................................................. 5

2.1 Conguration.................................................................................................................... 5

3 Mounting................................................................................................................................... 7

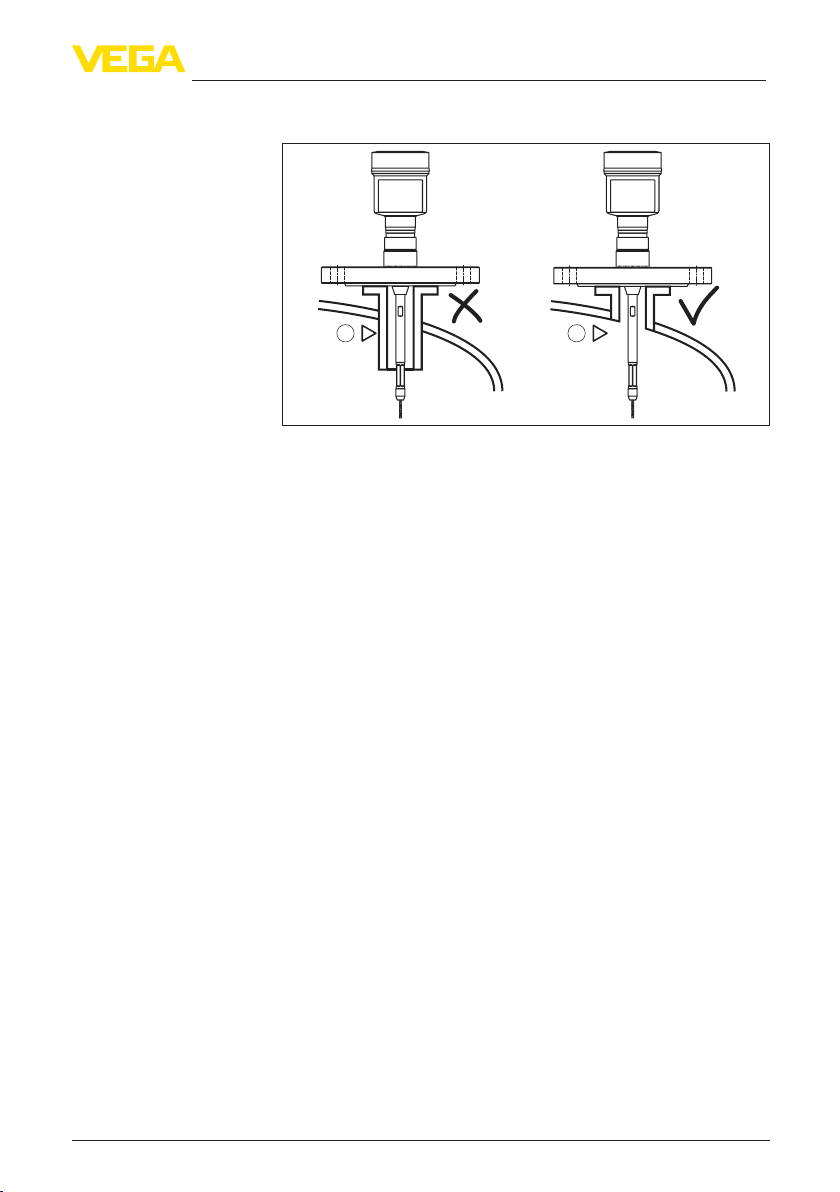

3.1 General instructions for use of the instrument .................................................................. 7

3.2 Mounting instructions ....................................................................................................... 7

4 Connecting to power supply................................................................................................. 10

4.1 Connecting..................................................................................................................... 10

4.2 Wiring plan, single chamber housing.............................................................................. 11

4.3 Wiring plan, double chamber housing ............................................................................ 11

5 Set up with the display and adjustment module ................................................................ 12

5.1 Insert display and adjustment module............................................................................ 12

5.2 Parameter adjustment .................................................................................................... 13

6 Set up with the display and adjustment module ................................................................ 15

6.1 Insert display and adjustment module............................................................................ 15

6.2 Parameter adjustment .................................................................................................... 16

7 Setup with smartphone/tablet (Bluetooth).......................................................................... 18

7.1 Preparations................................................................................................................... 18

7.2 Connecting..................................................................................................................... 19

7.3 Sensor parameter adjustment........................................................................................ 19

8 Supplement ............................................................................................................................ 20

8.1 Technical data ................................................................................................................ 20

Information:

This quick setup guide enables quick setup and commissioning of

your instrument.

Youcanndsupplementaryinformationinthecorresponding,more

detailed Operating Instructions Manual as well as the Safety Manual

thatcomeswithinstrumentswithSILqualication.Thesemanualsare

available on our homepage.

Operating instructions VEGAFLEX 81 - Two-wire 4 … 20 mA/

HART - Rod and cable probe - With SIL qualikation: Document-

ID 44219

Editing status of the quick setup guide: 2023-05-23