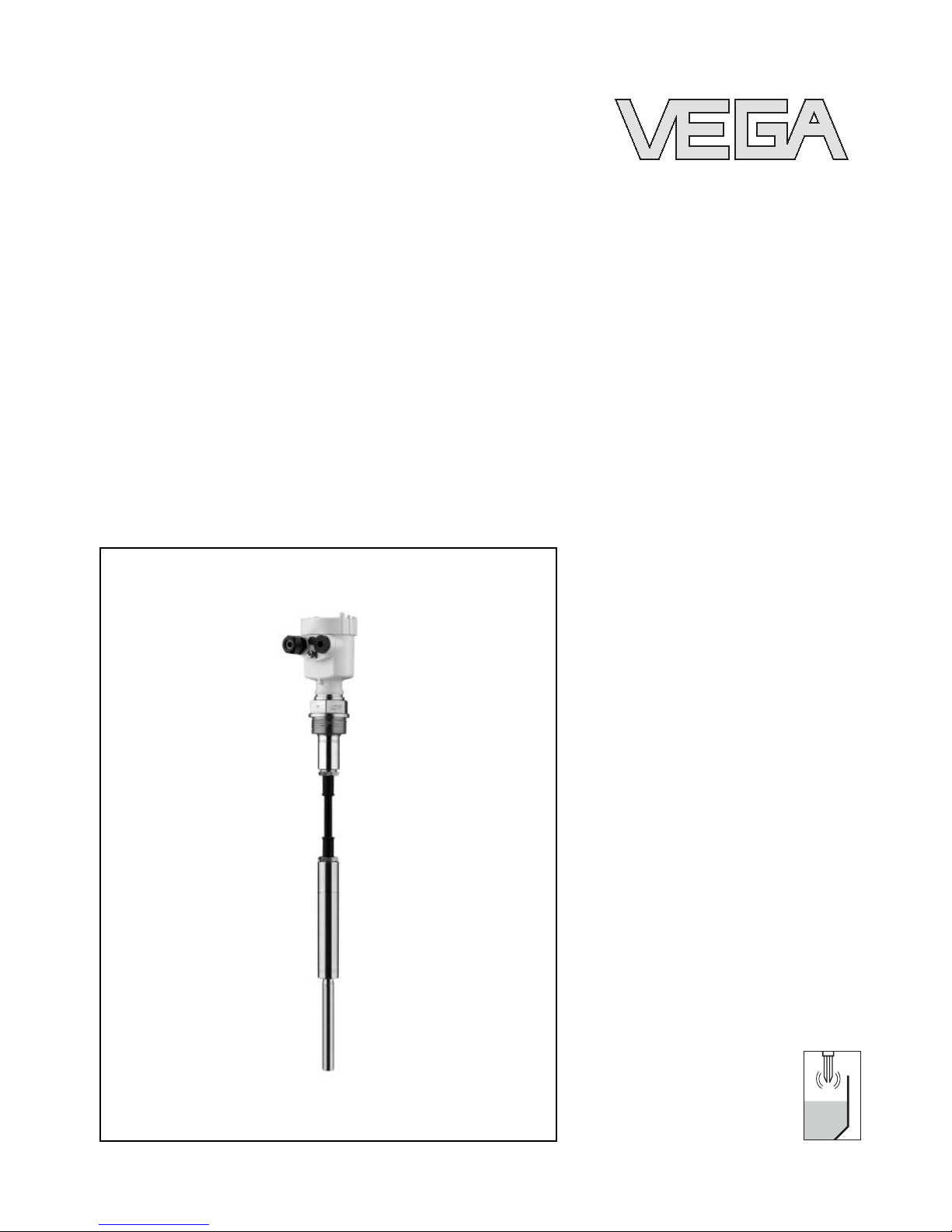

It is designed for industrial use in all areas of process

technology and is preferably used for bulk solids.

Typical applications are overfill and dry run protection.Thanks

to its simple and robust measuring system,VEGAVIB 62 is

virtually unaffected by the chemical and physical properties of

the bulk solid.

It functions even when exposed to strong external vibration or

changing products.

Solid detection in water

IfVEGAVIB 62 was ordered for solid detection in water,the

vibrating rod is to the density of water.In air or if covered by

water (density:1g/cm³/0.036 lbs/in)VEGAVIB 62 signals

uncovered.Only if the vibrating element is also covered with

solids (e.g.sand,sludge,gravel etc.) will the sensor signal

covered.

Fault monitoring

The electronics of VEGAVIB 62 continuously monitors the

following criteria:

lCorrect vibrating frequency

lLine break to the piezo drive

If one of the stated malfunctions is detected or in case of

power failure,the electronics takes on a defined switching

condition,i.e.the relay deenergises (safe condition).

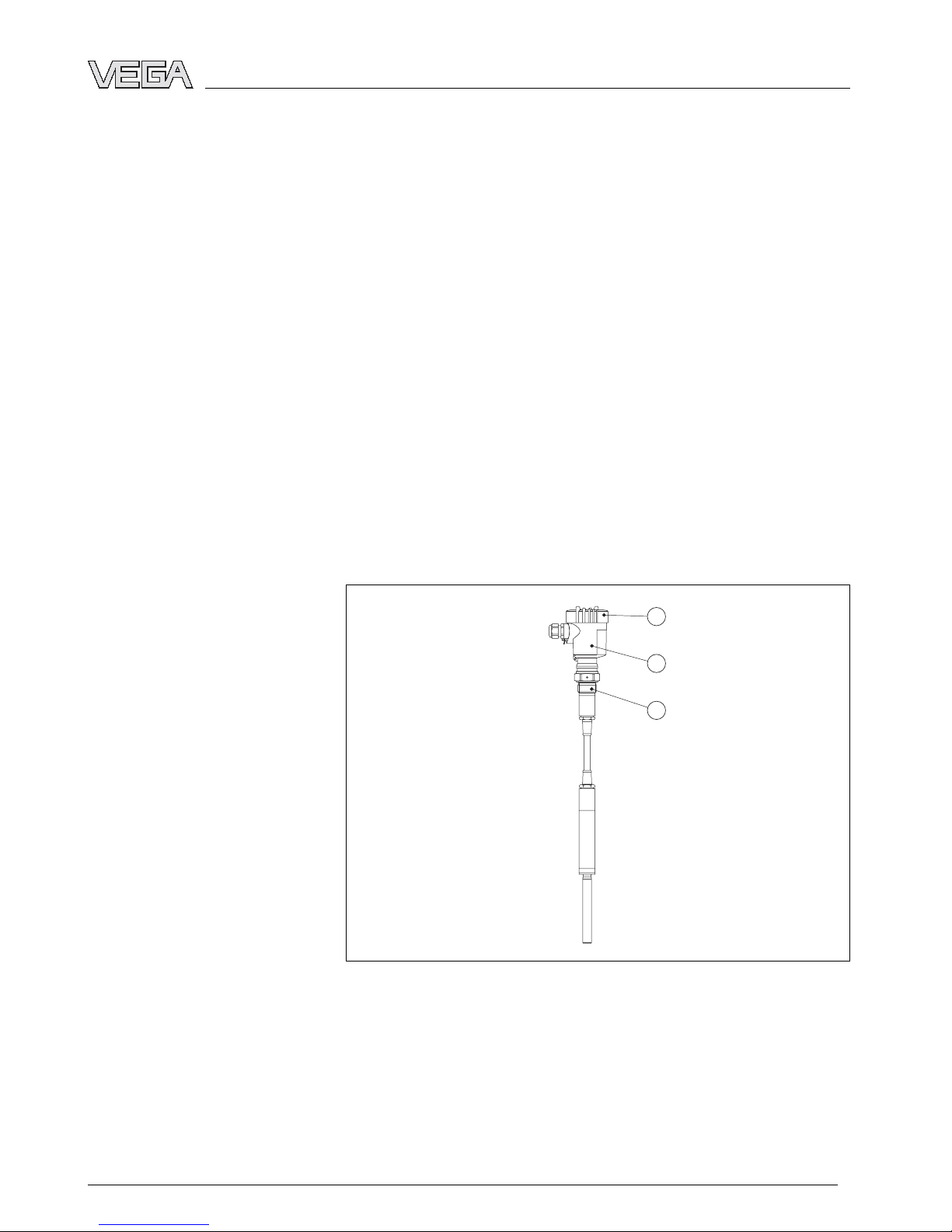

The vibrating rod is piezoelectrically energised and vibrates at

its mechanical resonance frequency of approx.360 Hz.When

the vibrating rod is submerged in the product,the vibration

amplitude changes.This change is detected by the integrated

oscillator and converted into a switching command.

VEGAVIB 62 is a compact instrument,i.e.it can be operated

without external evaluation system.The integrated electronics

evaluates the level signal and outputs a switching signal.With

this switching signal,a connected device can be operated

directly (e.g.a warning system,aPLC,a pump etc.).

The data for power supply are stated in chapter "Technical

data"in the "Supplement".

Functional principle

Supply

8VEGAVIB 62 --double relay (DPDT)

Product description

29271-EN-070116