2

Contents

VEGABAR 86 • 4 … 20 mA

45506-EN-230914

Contents

1 About this document ............................................................................................................... 4

1.1 Function ........................................................................................................................... 4

1.2 Target group ..................................................................................................................... 4

1.3 Symbols used................................................................................................................... 4

2 For your safety ......................................................................................................................... 5

2.1 Authorised personnel ....................................................................................................... 5

2.2 Appropriate use................................................................................................................ 5

2.3 Warning about incorrect use............................................................................................. 5

2.4 General safety instructions............................................................................................... 5

2.5 Conformity........................................................................................................................ 5

2.6 NAMUR recommendations .............................................................................................. 6

2.7 Installation and operation in the USA and Canada ........................................................... 6

2.8 Environmental instructions ............................................................................................... 6

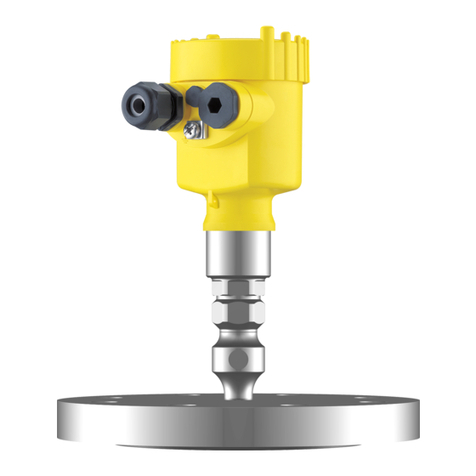

3 Product description ................................................................................................................. 7

3.1 Conguration.................................................................................................................... 7

3.2 Principle of operation........................................................................................................ 7

3.3 Packaging, transport and storage................................................................................... 10

3.4 Accessories.................................................................................................................... 11

4 Mounting................................................................................................................................. 12

4.1 General instructions ....................................................................................................... 12

4.2 Ventilation and pressure compensation.......................................................................... 14

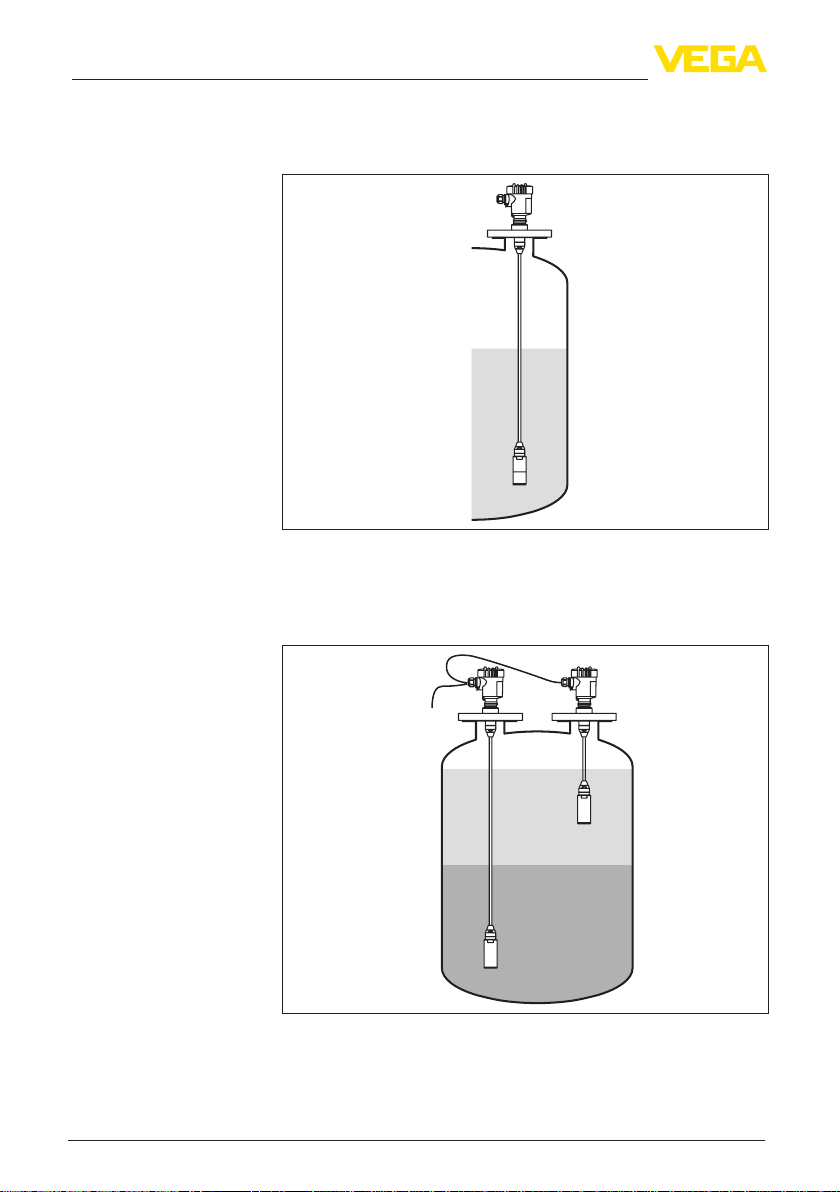

4.3 Level measurement........................................................................................................ 17

4.4 External housing ............................................................................................................ 17

5 Connecting to power supply................................................................................................. 18

5.1 Preparing the connection ............................................................................................... 18

5.2 Connecting..................................................................................................................... 19

5.3 Single chamber housing................................................................................................. 20

5.4 Housing IP66/IP68 (1 bar) .............................................................................................. 21

5.5 External housing ............................................................................................................ 22

5.6 Switch-on phase............................................................................................................. 23

6 Set up with the display and adjustment module ................................................................ 24

6.1 Insert display and adjustment module............................................................................ 24

6.2 Adjustment system......................................................................................................... 25

6.3 Measured value indication.............................................................................................. 26

6.4 Parameter adjustment - Quick setup .............................................................................. 27

6.5 Parameter adjustment - Extended adjustment................................................................ 27

6.6 Menu overview ............................................................................................................... 39

6.7 Save parameter adjustment data.................................................................................... 40

7 Setup with PACTware............................................................................................................. 41

7.1 Connect the PC.............................................................................................................. 41

7.2 Parameterization ............................................................................................................ 41

7.3 Save parameter adjustment data.................................................................................... 42

8 Set up with other systems .................................................................................................... 43

8.1 DD adjustment programs ............................................................................................... 43

8.2 Field Communicator 375, 475 ........................................................................................ 43

9 Diagnostics and servicing .................................................................................................... 44