Screw: Brass UNS-C36000

Painted black for appearance only.

Pip Cap: Copper UNS-C11000 and

Stainless Steel UNS-S30400,Tef-

lon®Coated

ACCESSORIES

Sprinkler Wrenches:

•Standard Wrench: Part No.

05000CW/B

•Wrenchforcoatedandrecessed

Microfast®Sidewall Sprinklers:

Part No. 07398W*

* A ½" ratchet is required (not available from Vi-

king).

Refer to the “SPRINKLER ACCES-

SORIES” section of the Viking Engi-

neering and Design Databook for tech-

nical data on approved escutcheons

and other accessories.

5. AVAILABILITY AND SERVICE

Vikingsprinklersare available through a

network of domestic, Canadian, and in-

ternational distributors. See the Yellow

Pages of the telephone directory (listed

under “Sprinklers-Automatic-Fire”) for a

local distributor, or contact Viking.

Viking Technical Data may be found on

The Viking Corporation’s Web site at

http://www.vikingcorp.com.

The Web site may include a more recent

edition of this Technical Data page.

6. GUARANTEES

For details of warranty, refer to Viking’s

currentlistpricescheduleorcontactThe

Viking Corporation directly.

7. INSTALLATION

WARNING:Viking sprinklers are manu-

factured and tested to meet the rigid re-

quirements of approving agencies. The

sprinklersare designed tobeinstalledin

accordance with recognized installation

standards.Deviationfromthestandards

or any alteration to the sprinkler after it

leaves the factory including, but not lim-

ited to: painting, plating, coating, or

modification, may render the sprinkler

inoperative and will automatically nullify

the approval and any guarantee made

by The Viking Corporation.

A.Sprinklers aretobeinstalledinaccor-

dance with the latest published stan-

dards of the National Fire Protection

Association, Factory Mutual, Loss

Prevention Council, Assemblee

Pleniere, Verband der

Sachversicherer or other similar or-

ganizations, and also with the provi-

sions of governmental codes, ordi-

nances,andstandardswheneverap-

plicable. The use of quick response

sidewall sprinklers may be limited

due to occupancy and hazard. Refer

to the Authority Having Jurisdiction

prior to installation.

B.Sprinklersmustbehandled withcare.

They must be stored in a cool, dry

place in their original shipping con-

tainer. Never install sprinklers that

have been dropped, damaged in any

way, or exposed to temperatures in

excess of the maximum ambient

temperature allowed. Never install

any glass-bulb sprinkler if the bulb is

cracked or if there is a loss of liquid

fromthebulb.Ifaglassbulblacksthe

appropriate amount of fluid, it should

be set aside and returned to Viking

(or an authorized Viking distributor)

for analysis as soon as possible. If

thesprinkleris not returned toViking,

it should be destroyed immediately.

C. Corrosion-resistant sprinklers must

be installed when subject to corro-

sive atmospheres. When installing

corrosion-resistant sprinklers, take

care not to damage the corro-

sion-resistant coating. Use only the

special wrench designed for install-

ing coated Viking sprinklers (any

otherwrenchmaydamagetheunit).

D. Use care when locating sprinklers

near fixtures that can generate heat.

Do not install sprinklers where they

will be exposed to temperatures that

exceed the maximum recommended

ambient temperature for the temper-

ature rating used.

E. Before installation, be sure to have

the appropriate sprinkler model and

style, with the proper orifice size,

temperature rating, and response

characteristics.

For allowable deflector distance be-

low ceiling of Microfast®Model M /

M-5 Quick Response Horizontal

Sidewall Sprinklers, refer to approval

chart on page 52 c. Align top of hori-

zontal sidewall deflectors parallel to

the ceiling or roof.

Locate deflectors of Microfast®

ModelM/M-5QuickResponseVerti-

cal Sidewall Upright Sprinklers 4" to

6" (102 mm to 152 mm) below the

ceiling (see approval chart).

Locate deflectors of Microfast®

ModelM/M-5QuickResponseVerti-

calSidewallPendentSprinklersupto

6" (152 mm) below the ceiling (see

approval chart).

Installsidewallsprinklers withdeflec-

tors located 4" to 6" (102 mm to 152

mm)fromwalls.Exception:Sidewall

sprinklers may be installed less than

4" (102 mm) from the wall on which

they are mounted.

The sprinklers must be installed after

the piping is in place to prevent me-

chanical damage.

1. Installescutcheon(if used),which

is designed to thread onto the ex-

ternalthreadsofthesprinkler.Re-

fer to the “Sprinkler Accessories”

section of the Viking Engineering

and Design Databook for ap-

proved escutcheons and other

accessories.

2. Apply a small amount of pipe-joint

compound or tape to the external

threads of the sprinkler only, tak-

ing care not to allow a build-up of

compound in the sprinkler inlet.

3. Install the sprinkler on the piping

usingthespecial sprinklerwrench

only, taking care not to

over-tighten or damage the sprin-

kler operating parts. DO NOT use

the deflector to start or thread the

sprinkler into a fitting.

F. After installation, the entire sprinkler

systemmustbetestedinaccordance

with the recognized installation stan-

dards. The test is applied after sprin-

kler installation to ensure that no

damagehasoccurredtothesprinkler

during shipping and installation, and

to make sure the sprinkler has been

properly tightened. If a thread leak

occurs, normally the sprinkler must

be removed, new pipe-joint com-

pound or tape applied, and then rein-

stalled. This is due to the fact that

when the joint seal is damaged, the

sealing compound or tape is washed

out of the joint. Air testing the sprin-

kler piping prior to testing with water

may be considered in areas where

leakage during testing must be pre-

vented.RefertotheInstallationStan-

dardsand theAuthorityHaving Juris-

diction.

G. Sprinklers must be protected from

mechanical damage. Wet-pipe sys-

tems must be provided with ade-

quate heat. When installing quick re-

sponsesprinklersondrysystems,re-

fer to the Installation Standards and

the Authority Having Jurisdiction.

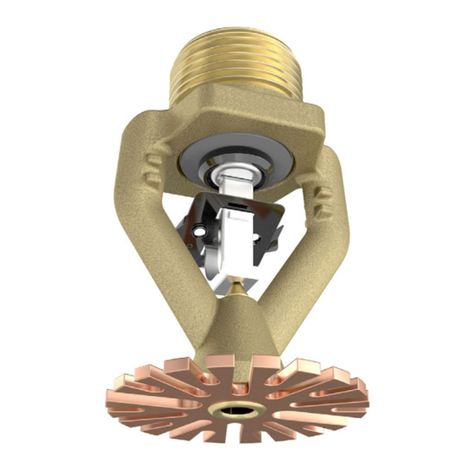

TECHNICAL DATAMicrofast ®MODEL M / M-5

QUICK RESPONSE

SIDEWALL SPRINKLER

Sprinkler 52 bJune 16, 1999