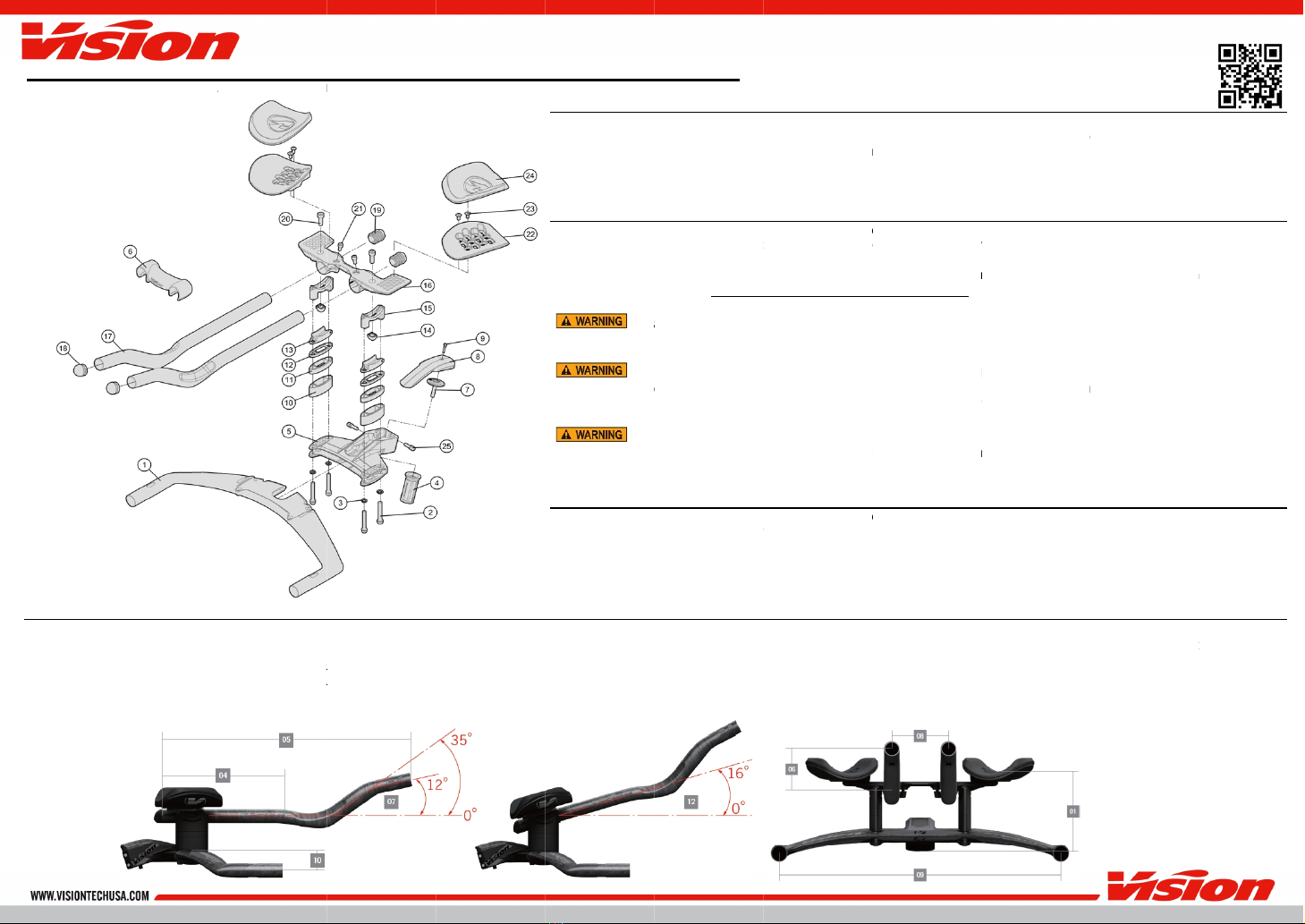

1.

Make certain that the diameterofthe steerertube matchesthe Vision Metron Snakebite StemSteererClamp size 1

2. Brake/

electronicwiringshouldberun throughthe Metron TFAAerobar BaseBar

StemBody

3.

4.

Use Angle Adjustment GripNut

5. Slid

unexpectedbar failure causingaccident andinjury.

6.

7.

To adjustangle ofaerobar extensions

⑭

slidesfreely.Set to desiredangle and

8.

9.

See Table 1forStack Spacer

10

.Remove the adhesive VelcroStr

11. Install the

12. Place

(

fore /aft orup/down free play) in theheadset assembly,while the bearings rotate freely (free steeringmotion).

13.

Ensurehandlebar is alignedstraight andgradually tighten th

NOT exceedmaximumtorque specification.Alwaysuse acalibratedtorque wrench.

14. Install

1.

Brake/electronicwiringshouldbe run through the Metron TFA Aerobar BaseBar

2.

3.

It maybenecessaryto trimaeroextensionsiftherear ofthe extension protrudesbehindthe mount.

Do not cut beyondthe (MIN^INSERT) lineindicators on the extensions. Cuttingbeyondthe line indicators may make it impossi

1.

Use asharp hacksaw blade forbest resultsonalloy aerobars.Forcarbon aerobars, anabrasive blade will work best.Apply a

2.

Use acuttingguide forthe saw blade to ensure an even cutofthe aerobar. Cut the extensionto desiredlength.

3.

Remove any burrsorfrayedcarbon strandswit

4.

Install shifterpershiftermanufacturer sinstructions.

5. Use

6. Install

Armrest

Extension lengthadjustment

Make certain that the diameterofthe steerertube matchesthe Vision Metron Snakebite StemSteererClamp size 1

electronicwiringshouldberun throughthe Metron TFAAerobar BaseBar

.

r

into the slot on the StemBody

Use Angle Adjustment GripNut

⑰into

imuminsertion length indication on the AeroExtensions

unexpectedbar failure causingaccident andinjury.

To adjustangle ofaerobar extensions

slidesfreely.Set to desiredangle and

Pad Plates ○

22

fordesiredfit position using

See Table 1forStack Spacer

s

.Remove the adhesive VelcroStr

⑤

fore /aft orup/down free play) in theheadset assembly,while the bearings rotate freely (free steeringmotion).

Ensurehandlebar is alignedstraight andgradually tighten th

NOT exceedmaximumtorque specification.Alwaysuse acalibratedtorque wrench.

Plate ⑧to

Brake/electronicwiringshouldbe run through the Metron TFA Aerobar BaseBar

greatly improvedwhen usingaguide cable to gently pull the housingorelectronicwiresthrough the base bar fromeitherdir

⑩, ,

⑤

are designedONLY to allow electronicshiftingwiresto be run internally through the Stem Body

modifythecable guideholes. Do not drill,saw,orfiletheholes largerorto adifferentshape.Modificationswill voidwa

.

It maybenecessaryto trimaeroextensionsiftherear ofthe extension protrudesbehindthe mount.

Make

careful measurmentsbefore cuttingandbe sure ofthecut location.Cuttingan aero extension isaone

Do not cut beyondthe (MIN^INSERT) lineindicators on the extensions. Cuttingbeyondthe line indicators may make it impossi

Use asharp hacksaw blade forbest resultsonalloy aerobars.Forcarbon aerobars, anabrasive blade will work best.Apply a

Use acuttingguide forthe saw blade to ensure an even cutofthe aerobar. Cut the extensionto desiredlength.

Remove any burrsorfrayedcarbon strandswit

Install shifterpershiftermanufacturer sinstructions.

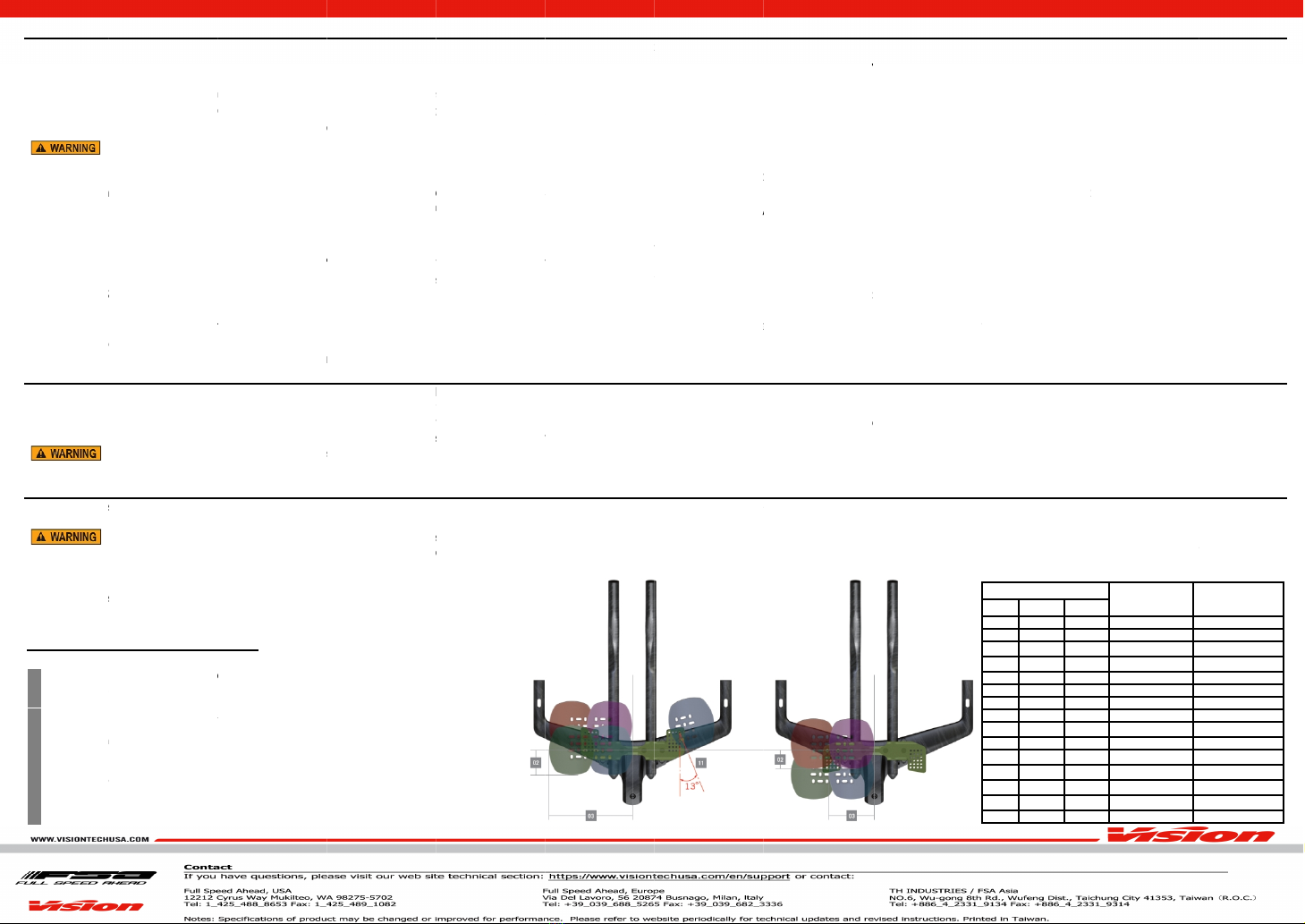

Bridge ⑥

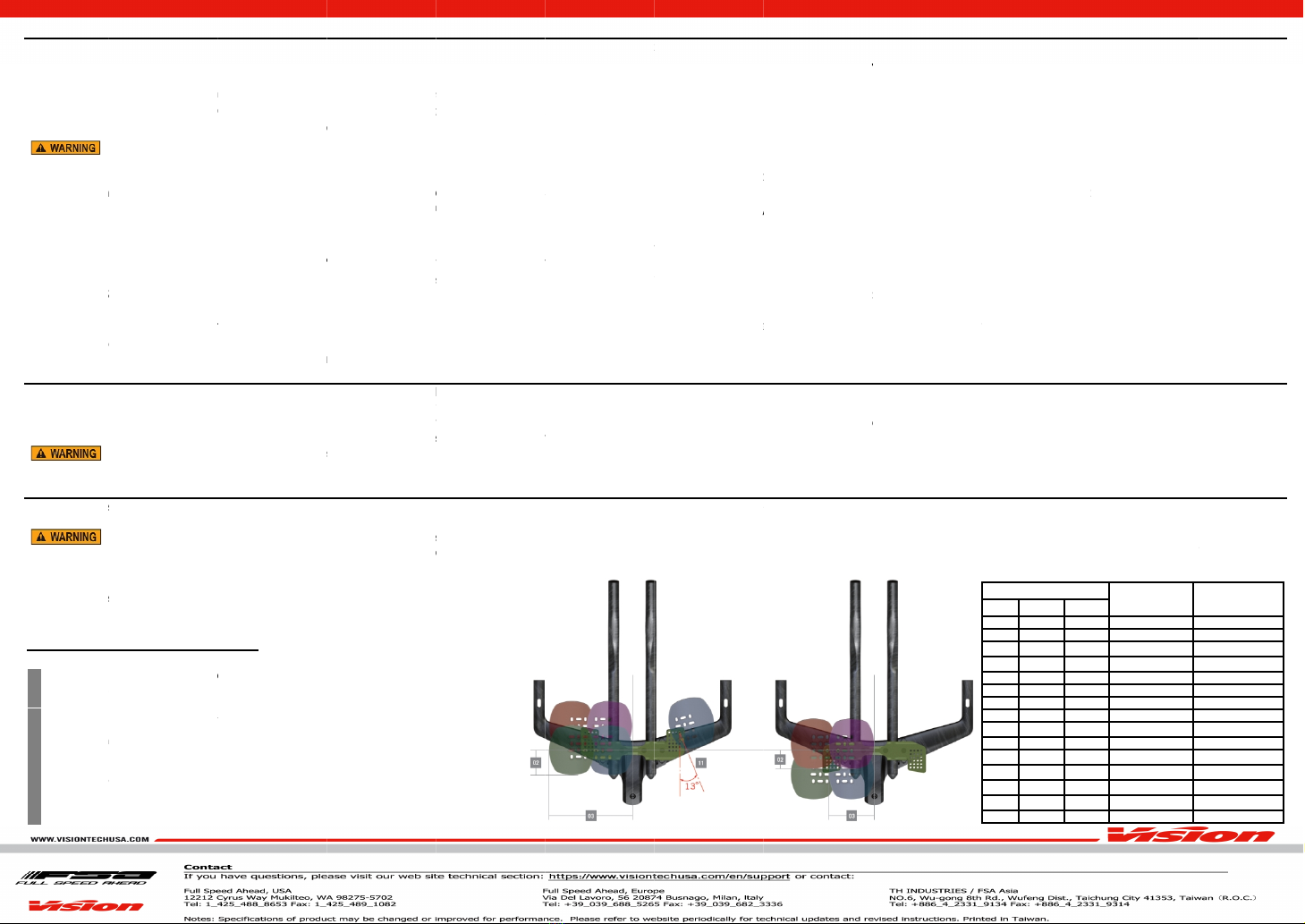

(Bottom ofstem atcenter to top of uncompressed pad

(Center of Basebar to rear edge of armrest

Extension lengthadjustment

245mm to385mm(Center of Basebar toTip)

Make certain that the diameterofthe steerertube matchesthe Vision Metron Snakebite StemSteererClamp size 1

electronicwiringshouldberun throughthe Metron TFAAerobar BaseBar

into the slot on the StemBody

⑯

.Set todesiredlength androtation angle.Tighten AngleAdjustment Bolt

imuminsertion length indication on the AeroExtensions

unexpectedbar failure causingaccident andinjury.

⑬

underUpperAngleAdjustment Bracket

To adjustangle ofaerobar extensions

⑰,Use

slidesfreely.Set to desiredangle and

tighten

fordesiredfit position using

, , ⑫

.Remove the adhesive VelcroStr

ips fromArmrest

④

,t

ighten the Compression Cap

fore /aft orup/down free play) in theheadset assembly,while the bearings rotate freely (free steeringmotion).

Ensurehandlebar is alignedstraight andgradually tighten th

NOT exceedmaximumtorque specification.Alwaysuse acalibratedtorque wrench.

⑤use

Brake/electronicwiringshouldbe run through the Metron TFA Aerobar BaseBar

greatly improvedwhen usingaguide cable to gently pull the housingorelectronicwiresthrough the base bar fromeitherdir

⑫

arebeingusedin conjunction with wiredelectronicshiftingon

are designedONLY to allow electronicshiftingwiresto be run internally through the Stem Body

modifythecable guideholes. Do not drill,saw,orfiletheholes largerorto adifferentshape.Modificationswill voidwa

It maybenecessaryto trimaeroextensionsiftherear ofthe extension protrudesbehindthe mount.

careful measurmentsbefore cuttingandbe sure ofthecut location.Cuttingan aero extension isaone

Do not cut beyondthe (MIN^INSERT) lineindicators on the extensions. Cuttingbeyondthe line indicators may make it impossi

Use asharp hacksaw blade forbest resultsonalloy aerobars.Forcarbon aerobars, anabrasive blade will work best.Apply a

Use acuttingguide forthe saw blade to ensure an even cutofthe aerobar. Cut the extensionto desiredlength.

Remove any burrsorfrayedcarbon strandswit

Install shifterpershiftermanufacturer sinstructions.

overcable housingandpress into Aero Extensio

.

(Bottom ofstem atcenter to top of uncompressed pad

(Center of Basebar to rear edge of armrest

245mm to385mm(Center of Basebar toTip)

Make certain that the diameterofthe steerertube matchesthe Vision Metron Snakebite StemSteererClamp size 1

electronicwiringshouldberun throughthe Metron TFAAerobar BaseBar

into the slot on the StemBody

⑤.T

ighten the SteererClampBolt

⑳

to install theUpperAngle Adjustment Bracket

.Set todesiredlength androtation angle.Tighten AngleAdjustment Bolt

imuminsertion length indication on the AeroExtensions

underUpperAngleAdjustment Bracket

fordesiredfit position using

Armrest

ads ○

24

andattach to the topsurface ofleft andright

.

Tighten the ExpanderAssembly with a6mm

ighten the Compression Cap

fore /aft orup/down free play) in theheadset assembly,while the bearings rotate freely (free steeringmotion).

Ensurehandlebar is alignedstraight andgradually tighten th

e

NOT exceedmaximumtorque specification.Alwaysuse acalibratedtorque wrench.

⑨

Brake/electronicwiringshouldbe run through the Metron TFA Aerobar BaseBar

greatly improvedwhen usingaguide cable to gently pull the housingorelectronicwiresthrough the base bar fromeitherdir

arebeingusedin conjunction with wiredelectronicshiftingon

are designedONLY to allow electronicshiftingwiresto be run internally through the Stem Body

modifythecable guideholes. Do not drill,saw,orfiletheholes largerorto adifferentshape.Modificationswill voidwa

It maybenecessaryto trimaeroextensionsiftherear ofthe extension protrudesbehindthe mount.

careful measurmentsbefore cuttingandbe sure ofthecut location.Cuttingan aero extension isaone

Do not cut beyondthe (MIN^INSERT) lineindicators on the extensions. Cuttingbeyondthe line indicators may make it impossi

Use asharp hacksaw blade forbest resultsonalloy aerobars.Forcarbon aerobars, anabrasive blade will work best.Apply a

Use acuttingguide forthe saw blade to ensure an even cutofthe aerobar. Cut the extensionto desiredlength.

Install shifterpershiftermanufacturer sinstructions.

overcable housingandpress into Aero Extensio

(Bottom ofstem atcenter to top of uncompressed pad

(Center of Basebar to rear edge of armrest

245mm to385mm(Center of Basebar toTip)

Make certain that the diameterofthe steerertube matchesthe Vision Metron Snakebite StemSteererClamp size 1

electronicwiringshouldberun throughthe Metron TFAAerobar BaseBar

beforei

ighten the SteererClampBolt

to install theUpperAngle Adjustment Bracket

.Set todesiredlength androtation angle.Tighten AngleAdjustment Bolt

imuminsertion length indication on the AeroExtensions

⑰

underUpperAngleAdjustment Bracket

⑮

makingsure to align the wiringgrov

orthree

full turnsall 4Extension WidthSpacerBolts

with Angle Ad

FixingBolts ○

23 .

Armrest Pad

andattach to the topsurface ofleft andright

Tighten the ExpanderAssembly with a6mm

ighten the Compression Cap

&Bolt ⑦

with a4mm hex wrenchto until properbearingpreload is achieved. Note: Properbearingpreload isapparent when thereisno

fore /aft orup/down free play) in theheadset assembly,while the bearings rotate freely (free steeringmotion).

t ○

25

byalternatingturningeachscrews1/4to 1/2turnatatimesoboth screwstighten sim

NOT exceedmaximumtorque specification.Alwaysuse acalibratedtorque wrench.

Torque to 10

Brake/electronicwiringshouldbe run through the Metron TFA Aerobar BaseBar

before installingStemBody

greatly improvedwhen usingaguide cable to gently pull the housingorelectronicwiresthrough the base bar fromeitherdir

arebeingusedin conjunction with wiredelectronicshiftingon

are designedONLY to allow electronicshiftingwiresto be run internally through the Stem Body

modifythecable guideholes. Do not drill,saw,orfiletheholes largerorto adifferentshape.Modificationswill voidwa

It maybenecessaryto trimaeroextensionsiftherear ofthe extension protrudesbehindthe mount.

careful measurmentsbefore cuttingandbe sure ofthecut location.Cuttingan aero extension isaone

Do not cut beyondthe (MIN^INSERT) lineindicators on the extensions. Cuttingbeyondthe line indicators may make it impossi

Use asharp hacksaw blade forbest resultsonalloy aerobars.Forcarbon aerobars, anabrasive blade will work best.Apply a

Use acuttingguide forthe saw blade to ensure an even cutofthe aerobar. Cut the extensionto desiredlength.

overcable housingandpress into Aero Extensio

n ⑰.

Make certain that the diameterofthe steerertube matchesthe Vision Metron Snakebite StemSteererClamp size 1

ing

to stem.The Metron TFA Aerobar BaseBar

ighten the SteererClampBolt

○

25

to install theUpperAngle Adjustment Bracket

.Set todesiredlength androtation angle.Tighten AngleAdjustment Bolt

makingsure to align the wiringgrov

full turnsall 4Extension WidthSpacerBolts

⑭

to 41

○

22

andattach to the topsurface ofleft andright

Tighten the ExpanderAssembly with a6mm

with a4mm hex wrenchto until properbearingpreload is achieved. Note: Properbearingpreload isapparent when thereisno

fore /aft orup/down free play) in theheadset assembly,while the bearings rotate freely (free steeringmotion).

byalternatingturningeachscrews1/4to 1/2turnatatimesoboth screwstighten sim

1Nm/9in.lbs.

before installingStemBody

greatly improvedwhen usingaguide cable to gently pull the housingorelectronicwiresthrough the base bar fromeitherdir

arebeingusedin conjunction with wiredelectronicshiftingon

are designedONLY to allow electronicshiftingwiresto be run internally through the Stem Body

modifythecable guideholes. Do not drill,saw,orfiletheholes largerorto adifferentshape.Modificationswill voidwa

It maybenecessaryto trimaeroextensionsiftherear ofthe extension protrudesbehindthe mount.

Aerobarscanonly becut fromthe rear. DoNOT cut the aerobarsextensionsfromthe front.Cuttingaerobarsfromthe front wi

careful measurmentsbefore cuttingandbe sure ofthecut location.Cuttingan aero extension isaone

Do not cut beyondthe (MIN^INSERT) lineindicators on the extensions. Cuttingbeyondthe line indicators may make it impossi

Use asharp hacksaw blade forbest resultsonalloy aerobars.Forcarbon aerobars, anabrasive blade will work best.Apply a

Use acuttingguide forthe saw blade to ensure an even cutofthe aerobar. Cut the extensionto desiredlength.

Make certain that the diameterofthe steerertube matchesthe Vision Metron Snakebite StemSteererClamp size 1

-1/8”

to stem.The Metron TFA Aerobar BaseBar

to install theUpperAngle Adjustment Bracket

⑮to theBridge ⑯

to torque of71

kgf.cm /7Nm/62 in.lbs., then tighten Extension Fixingbolts

the Bridge ⑯

ends. Ridingthe bar without the “MIN^INSERT”line inside the mountcan cause damage and

makingsure to align the wiringgrov

es.

full turnsall 4Extension WidthSpacerBolts

②

71 kgf.cm /7

/4 Nm/35 in.lbs.

.

○

22 .

61-92

with a4mm hex wrenchto until properbearingpreload is achieved. Note: Properbearingpreload isapparent when thereisno

fore /aft orup/down free play) in theheadset assembly,while the bearings rotate freely (free steeringmotion).

byalternatingturningeachscrews1/4to 1/2turnatatimesoboth screwstighten sim

before installingStemBody

⑤orBridge ⑯.

greatly improvedwhen usingaguide cable to gently pull the housingorelectronicwiresthrough the base bar fromeitherdir

Bracket

are designedONLY to allow electronicshiftingwiresto be run internally through the Stem Body

⑤ifdesired.

modifythecable guideholes. Do not drill,saw,orfiletheholes largerorto adifferentshape.Modificationswill voidwa

Aerobarscanonly becut fromthe rear. DoNOT cut the aerobarsextensionsfromthe front.Cuttingaerobarsfromthe front wi

careful measurmentsbefore cuttingandbe sure ofthecut location.Cuttingan aero extension isaone

-

time andfinal adjustment.

Do not cut beyondthe (MIN^INSERT) lineindicators on the extensions. Cuttingbeyondthe line indicators may make it impossi

Use asharp hacksaw blade forbest resultsonalloy aerobars.Forcarbon aerobars, anabrasive blade will work best.Apply a

layeroftape aroundareato be cut to reduce possibility ofcarbon frayingwhile

Use acuttingguide forthe saw blade to ensure an even cutofthe aerobar. Cut the extensionto desiredlength.

Fig.2

.

to stem.The Metron TFA Aerobar BaseBar

to fingertight.

kgf.cm /7Nm/62 in.lbs., then tighten Extension Fixingbolts

ends. Ridingthe bar without the “MIN^INSERT”line inside the mountcan cause damage and

③to

Extension Width SpacerBolts

5

mm hex key to loosen the AngleAdjustment Bolt

62 in.lbs.

Torque Extension Width SpacerBolts

6-9Nm/53-

with a4mm hex wrenchto until properbearingpreload is achieved. Note: Properbearingpreload isapparent when thereisno

41 kgf.cm

byalternatingturningeachscrews1/4to 1/2turnatatimesoboth screwstighten sim

greatly improvedwhen usingaguide cable to gently pull the housingorelectronicwiresthrough the base bar fromeitherdir

ection.

,

useelectricaltapeto holdwiringin the guideslotson the spac

modifythecable guideholes. Do not drill,saw,orfiletheholes largerorto adifferentshape.Modificationswill voidwa

rranty andmayresult infailureofthehandlebarwhile ridingcausingaccident,

Aerobarscanonly becut fromthe rear. DoNOT cut the aerobarsextensionsfromthe front.Cuttingaerobarsfromthe front wi

time andfinal adjustment.

Do not cut beyondthe (MIN^INSERT) lineindicators on the extensions. Cuttingbeyondthe line indicators may make it impossi

ble to install shifters into the extensions.

layeroftape aroundareato be cut to reduce possibility ofcarbon frayingwhile

-

25mm droporrisedependingon whichdirection

kgf.cm /7Nm/62 in.lbs., then tighten Extension Fixingbolts

ends. Ridingthe bar without the “MIN^INSERT”line inside the mountcan cause damage and

Extension Width SpacerBolts

mm hex key to loosen the AngleAdjustment Bolt

Torque Extension Width SpacerBolts

41 kgf.cm

.oftorque.

with a4mm hex wrenchto until properbearingpreload is achieved. Note: Properbearingpreload isapparent when thereisno

.

byalternatingturningeachscrews1/4to 1/2turnatatimesoboth screwstighten sim

useelectricaltapeto holdwiringin the guideslotson the spac

rranty andmayresult infailureofthehandlebarwhile ridingcausingaccident,

Aerobarscanonly becut fromthe rear. DoNOT cut the aerobarsextensionsfromthe front.Cuttingaerobarsfromthe front wi

time andfinal adjustment.

ble to install shifters into the extensions.

layeroftape aroundareato be cut to reduce possibility ofcarbon frayingwhile

Table 1: Armrest StackSpacer & Bolt Compatibility

25mm droporrisedependingon whichdirection

kgf.cm /7Nm/62 in.lbs., then tighten Extension Fixingbolts

ends. Ridingthe bar without the “MIN^INSERT”line inside the mountcan cause damage and

Extension Width SpacerBolts

②

mm hex key to loosen the AngleAdjustment Bolt

Torque Extension Width SpacerBolts

②to 81

.

with a4mm hex wrenchto until properbearingpreload is achieved. Note: Properbearingpreload isapparent when thereisno

byalternatingturningeachscrews1/4to 1/2turnatatimesoboth screwstighten sim

useelectricaltapeto holdwiringin the guideslotson the spac

rranty andmayresult infailureofthehandlebarwhile ridingcausingaccident,

Aerobarscanonly becut fromthe rear. DoNOT cut the aerobarsextensionsfromthe front.Cuttingaerobarsfromthe front wi

ble to install shifters into the extensions.

layeroftape aroundareato be cut to reduce possibility ofcarbon frayingwhile

Table 1: Armrest StackSpacer & Bolt Compatibility

25mm droporrisedependingon whichdirection

it

kgf.cm /7Nm/62 in.lbs., then tighten Extension Fixingbolts

○

21 to 41

ends. Ridingthe bar without the “MIN^INSERT”line inside the mountcan cause damage and

to 81 kgf.cm /8

mm hex key to loosen the AngleAdjustment Bolt

⑳

untilAngle Adjustment GripNut

8Nm/71

with a4mm hex wrenchto until properbearingpreload is achieved. Note: Properbearingpreload isapparent when thereisno

61

useelectricaltapeto holdwiringin the guideslotson the spac

ers.Small portson eitherside

rranty andmayresult infailureofthehandlebarwhile ridingcausingaccident,

Aerobarscanonly becut fromthe rear. DoNOT cut the aerobarsextensionsfromthe front.Cuttingaerobarsfromthe front wi

layeroftape aroundareato be cut to reduce possibility ofcarbon frayingwhile

Stackheight

10mm

15mm

40mm

50mm

55mm

60mm

65mm

Table 1: Armrest StackSpacer & Bolt Compatibility

isplacedinthe

.

ends. Ridingthe bar without the “MIN^INSERT”line inside the mountcan cause damage and

71 in.lbs.

untilAngle Adjustment GripNut

with a4mm hex wrenchto until properbearingpreload is achieved. Note: Properbearingpreload isapparent when thereisno

“knock”

.DO

ers.Small portson eitherside

rranty andmayresult infailureofthehandlebarwhile ridingcausingaccident,

Aerobarscanonly becut fromthe rear. DoNOT cut the aerobarsextensionsfromthe front.Cuttingaerobarsfromthe front wi

ll

Bolt length

45mm

50mm

75mm

85mm

90mm

95mm

100mm

Table 1: Armrest StackSpacer & Bolt Compatibility