TriMax Carbon SiInstallation Instructions

Published Jul,2021.ZS208B.v1 ©Full SpeedAhead

Congratulationson yourVision product.Please read these instructionsandfollow themforcorrect use.Failure to follow the

warningsandinstructionscouldresult in damageto productnot coveredunderwarranty,damageto bicycle;orcauseanaccident

resultingin injury ordeath.Since specifictoolsandexperience are necessary forproperinstallation,it isrecommendedthat the

product be installedby aqualifiedbicycle technician.FSA & Vision assumesno responsibility fordamagesorinjury relatedto

improperly installedcomponents.

Warranty

Full SpeedAhead (FSA) warrantsall FSA andVision productsto be free fromdefectsin materialsorworkmanshipforaperiodof

two years afteroriginalpurchaseunless otherwisestatedin thefull warranty policy.Thewarrantyisnon-transferable andvalidto

the originalpurchaserofthe productonly.Anyattempttomodify the productin any waysuchas drilling,grinding,andpaintingwill

voidthe warranty.Formore information on warranty policy andinstructionsforcompletingawarranty claim,check out the Full

Warranty Policy foundat ourwebsite:https://www.visiontechusa.com/en/technology

Alwaysuse acalibratedtorquewrench to tighten all screwsandboltswhen assemblingandadjustingthe vision

handlebar to the bicycle.Failuretouseacalibratedtorque wrenchcancausedamageto the handlebar makingit unsafeto rideand

isnot coveredunderwarranty.Check bolt andscrew torque before each ride toensure they have not loosenedduringuse.

Periodically inspectyourAerboars forany cracks, chips,scratches, andany othervisible damage.In the event ofan

accident do not ride the bicycle until the handlebarshave been inspectedby an experiencedmechanicas the aerobars may be

damagedorweakenedevenifnovisible damageisapparent.Ifthereisanyvisible damage,the aerobarsshouldnot beusedany

furtherandreplaced.

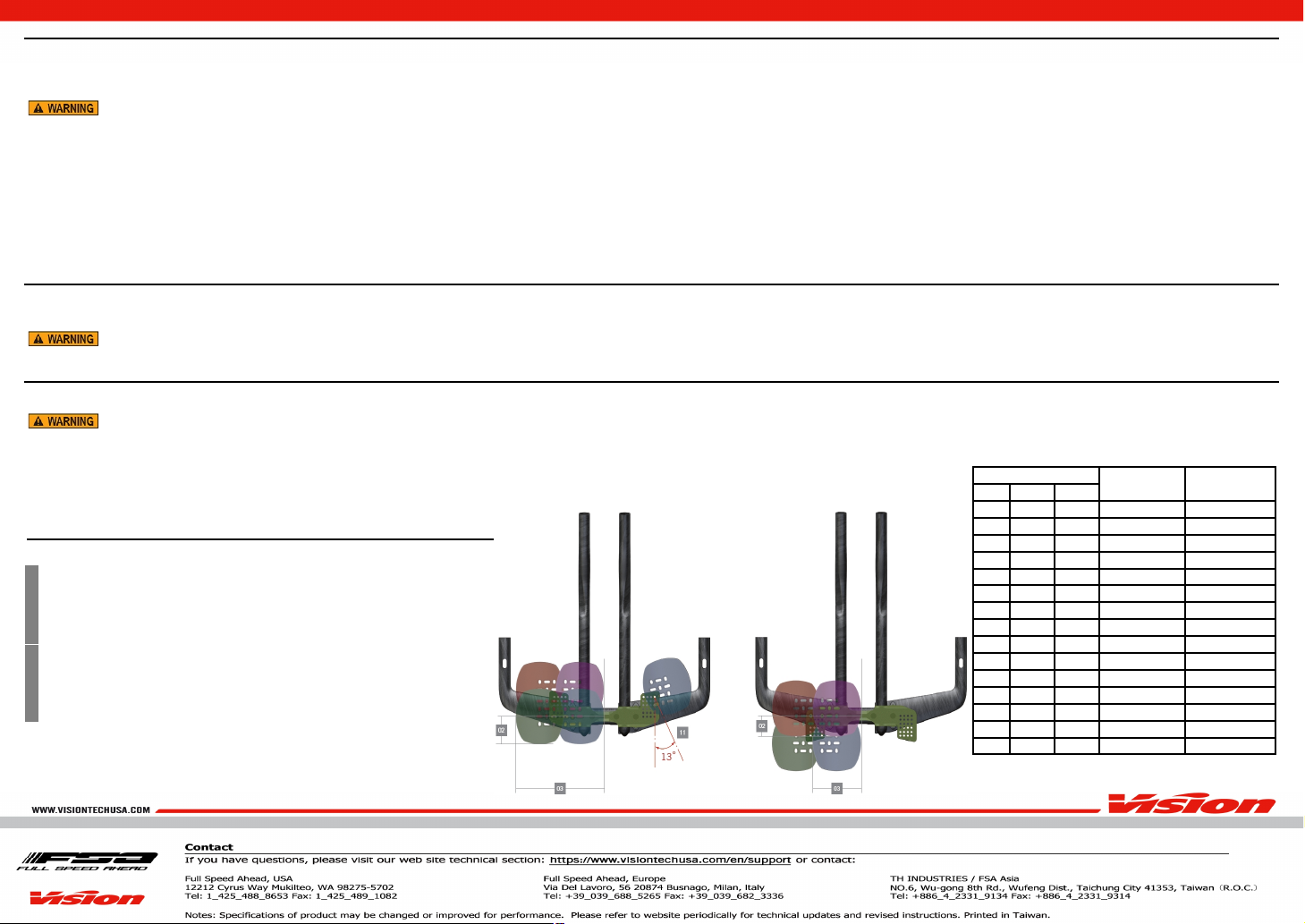

When changingthe ArmrestStackspacers , ⑤, ⑥,usethe correctlength bolt ②as perthe chartshow in Table 1.

Useonly FSA suppliedbolts.Failureto usethe correctlength bolt canresult in thread strippageofthe basebar,failureofbasebar,

andarmrest pad andcan cause seriousaccidentorinjury.

Specification

These instructionsare forthe installation andadjustment ofthe followingVision Brandcomponentsonly:

Model NameTriMaxCarbon Si

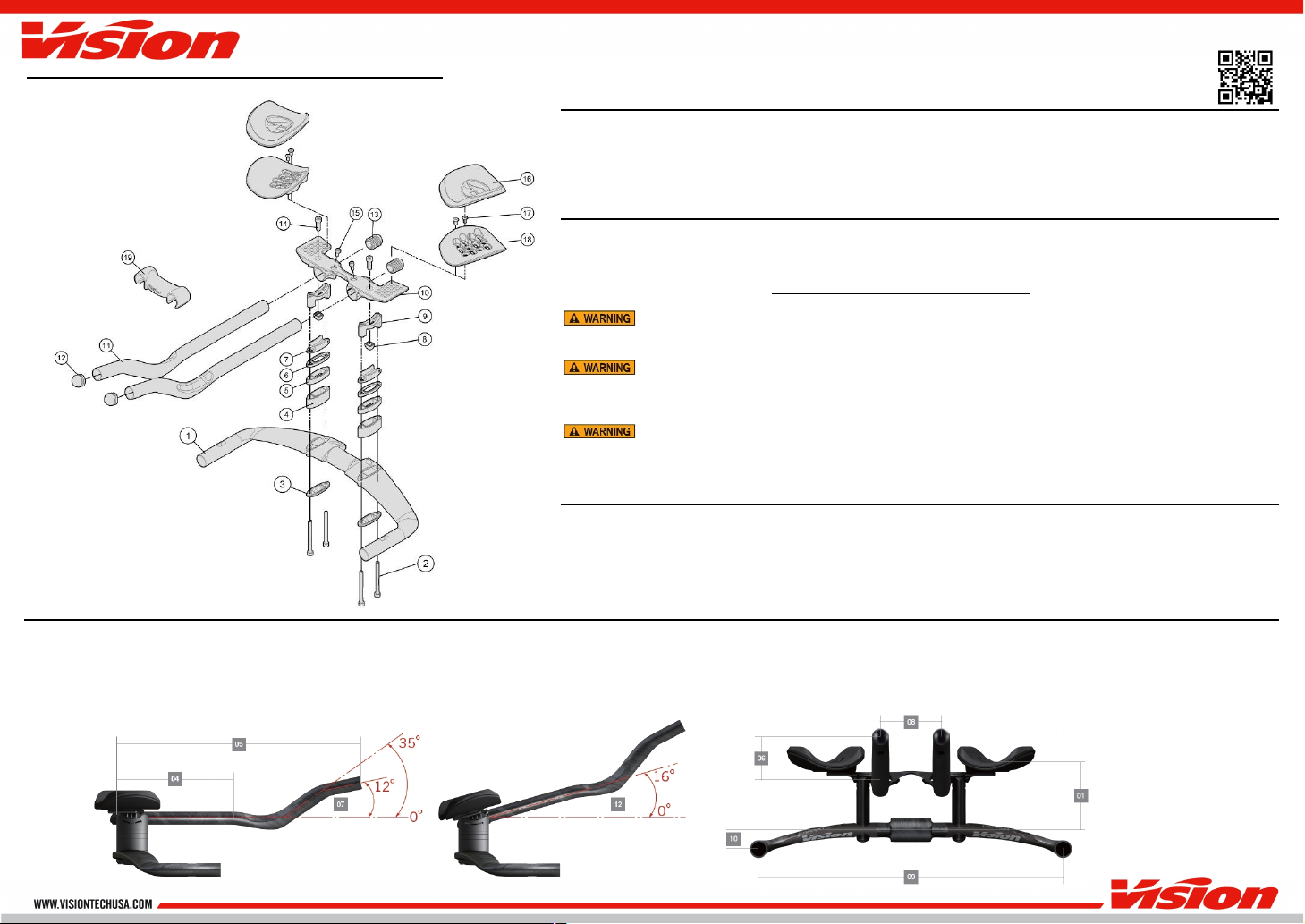

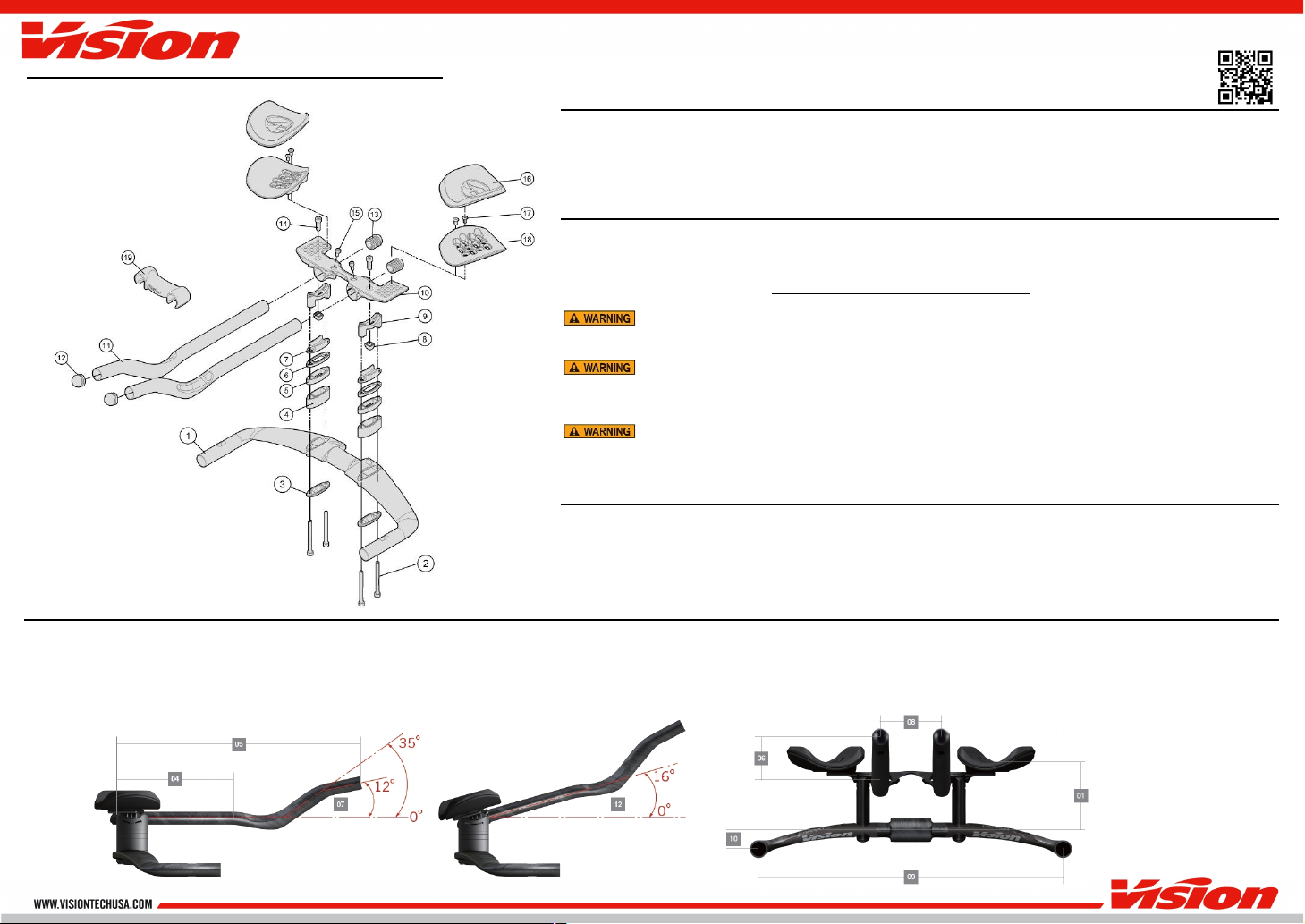

Follow the assembly orderin the illustration:

①

Extension Width SpacerBoltsx4②

③BottomCover x2

Armrest Stack Spacers (20mm) x6(AM)

Armrest Stack Spacers (10mm) x2(AM)⑤

Armrest Stack Spacers (5mm) x2(AM)⑥

LowerAngle Adjustment Bracket x2

⑦

⑧Angle Adjustment GripNut x2

⑨UpperAngle Adjustment Bracket x2

⑩Bridge x1

Aero Extension (Left & Right) x2

⑫

⑬Aero Extension Rear Plugx2

Angle Adjustment Bolt (M7x19mm) x2⑭

⑮Extension FixingBolts(M5x15mm) x2

⑯

Armrest Plate FixingBolts(M5x10mm) x4⑰

Armrest Pad Plate (Left & Right)⑱x2

⑲Extension Bridge x1

Fig.1