VISIONARY DESIGNS SEGUE VK-1308 User manual

Other VISIONARY DESIGNS Indoor Furnishing manuals

VISIONARY DESIGNS

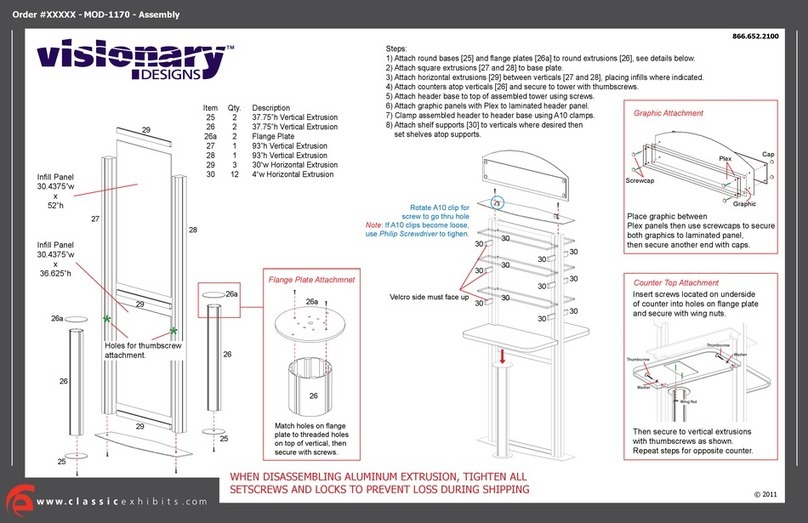

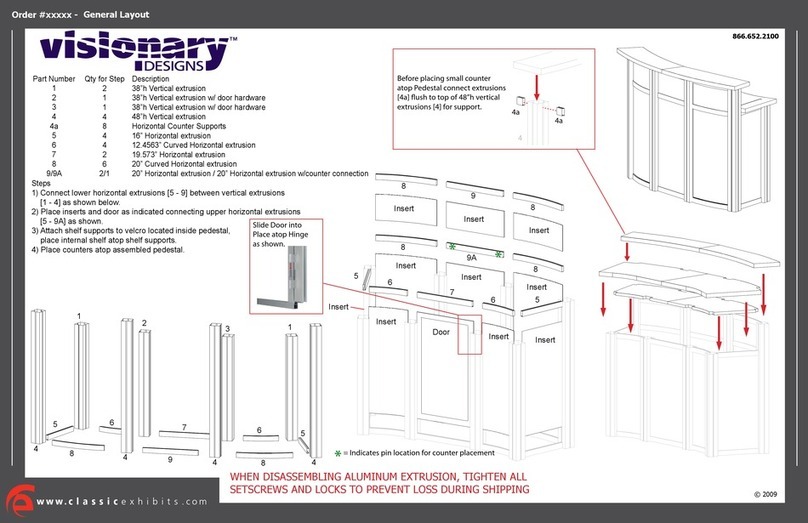

VISIONARY DESIGNS MOD-1170 User manual

VISIONARY DESIGNS

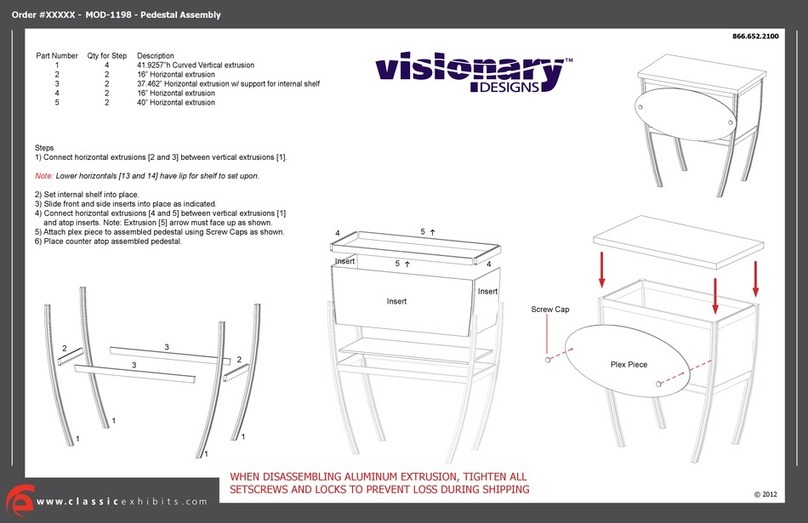

VISIONARY DESIGNS MOD-1198 Manual

VISIONARY DESIGNS

VISIONARY DESIGNS VK-5095 User manual

VISIONARY DESIGNS

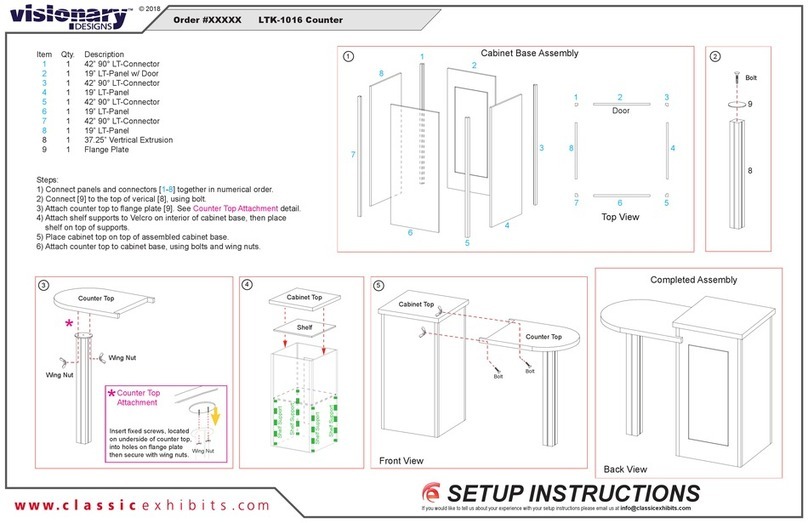

VISIONARY DESIGNS LTK-1016 Manual

VISIONARY DESIGNS

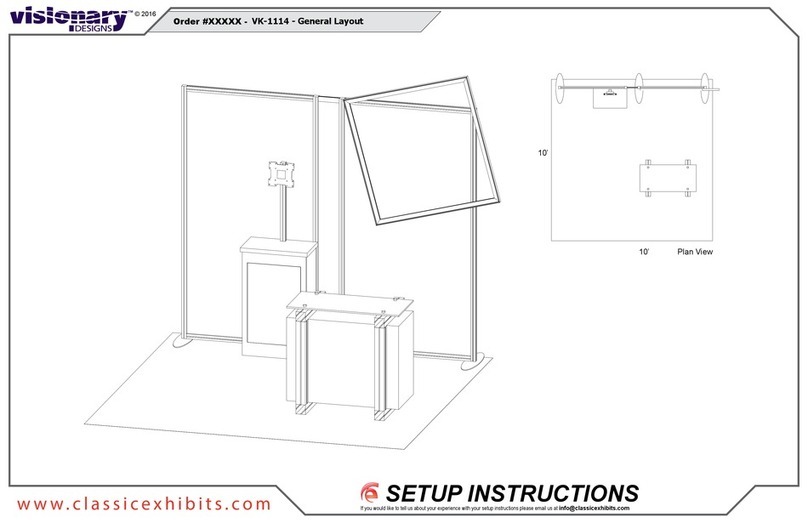

VISIONARY DESIGNS VK-1114 Manual

VISIONARY DESIGNS

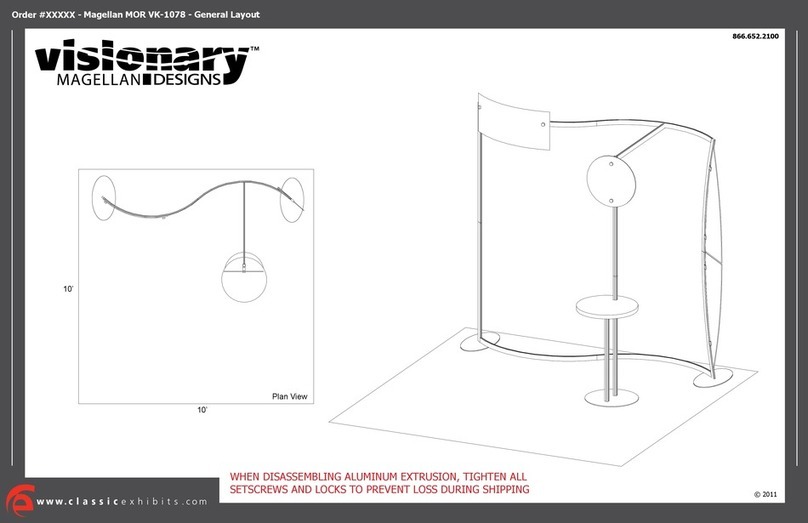

VISIONARY DESIGNS Magellan MOR VK-1078 Manual

VISIONARY DESIGNS

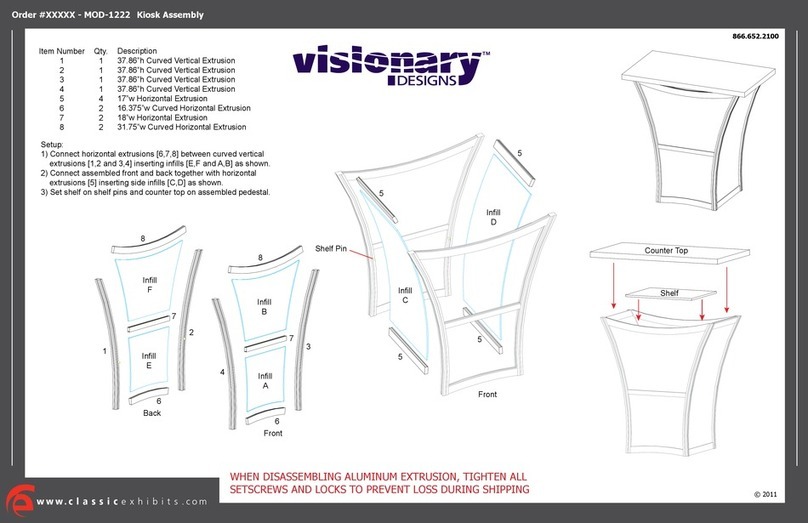

VISIONARY DESIGNS MOD-1222 User manual

VISIONARY DESIGNS

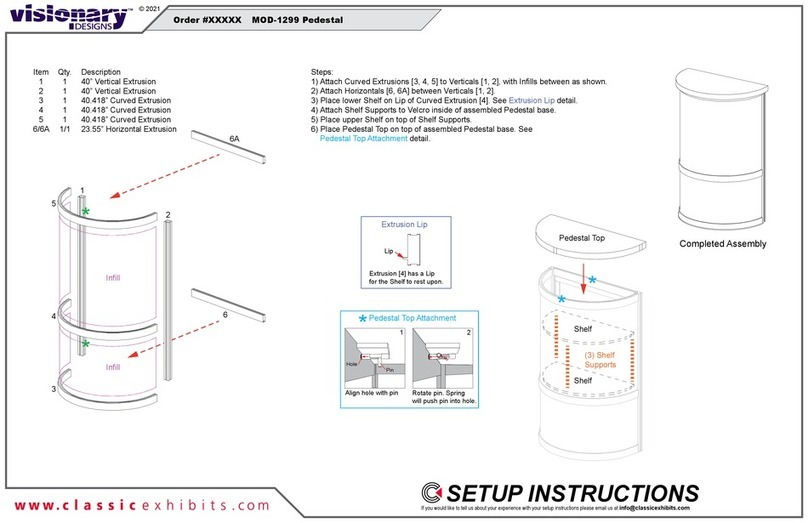

VISIONARY DESIGNS MOD-1299 Manual

VISIONARY DESIGNS

VISIONARY DESIGNS LTK-1001 User manual

VISIONARY DESIGNS

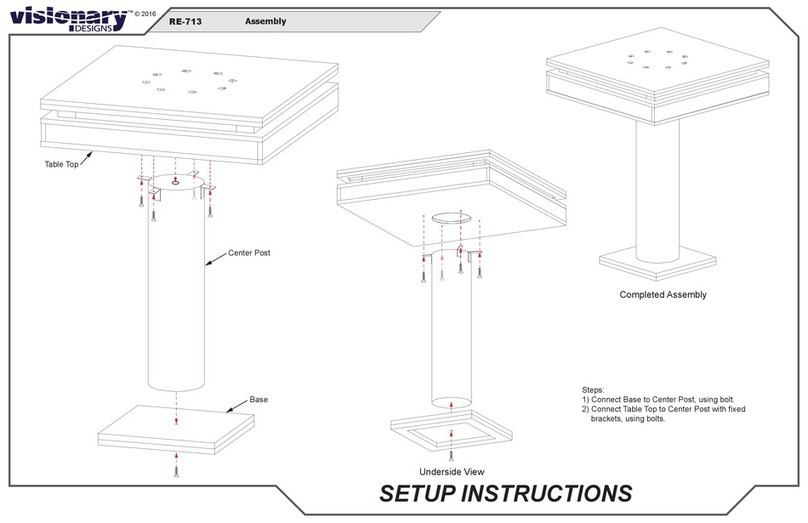

VISIONARY DESIGNS RE-713 Manual

VISIONARY DESIGNS

VISIONARY DESIGNS VK-1334 Manual

VISIONARY DESIGNS

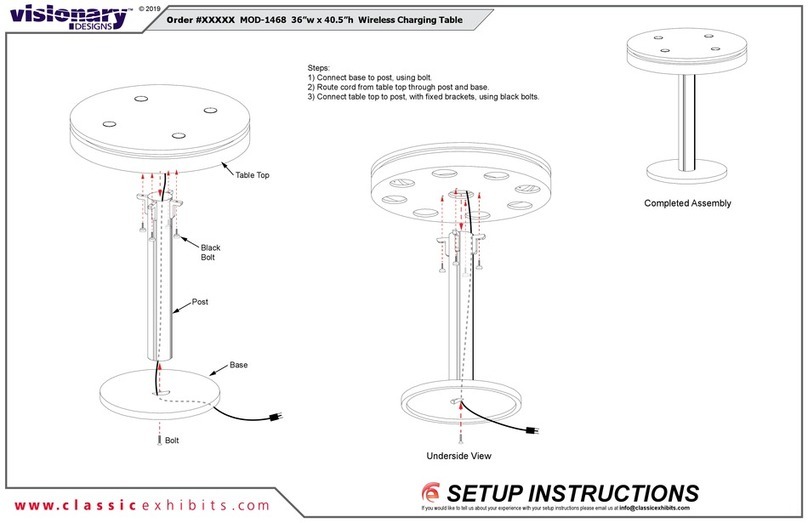

VISIONARY DESIGNS MOD-1468 User manual

VISIONARY DESIGNS

VISIONARY DESIGNS MOD-1143 User manual

VISIONARY DESIGNS

VISIONARY DESIGNS MOD-1441 User manual

VISIONARY DESIGNS

VISIONARY DESIGNS MOD-1185 Manual

VISIONARY DESIGNS

VISIONARY DESIGNS MOD-1514 Manual

VISIONARY DESIGNS

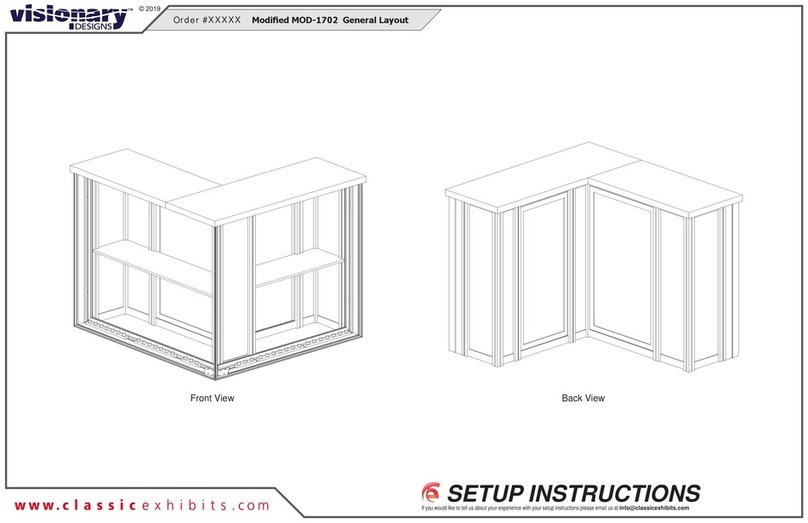

VISIONARY DESIGNS MOD-1702 Manual

VISIONARY DESIGNS

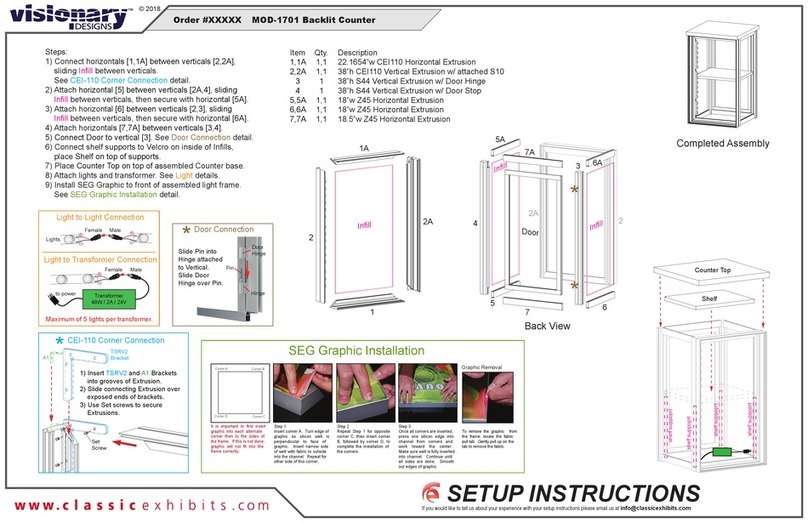

VISIONARY DESIGNS MOD-1701 User manual

VISIONARY DESIGNS

VISIONARY DESIGNS VK-1048 Manual

VISIONARY DESIGNS

VISIONARY DESIGNS MOD-1363 Manual

Popular Indoor Furnishing manuals by other brands

Regency

Regency LWMS3015 Assembly instructions

Furniture of America

Furniture of America CM7751C Assembly instructions

Safavieh Furniture

Safavieh Furniture Estella CNS5731 manual

PLACES OF STYLE

PLACES OF STYLE Ovalfuss Assembly instruction

Trasman

Trasman 1138 Bo1 Assembly manual

Costway

Costway JV10856 manual