165

74,50

4x

10

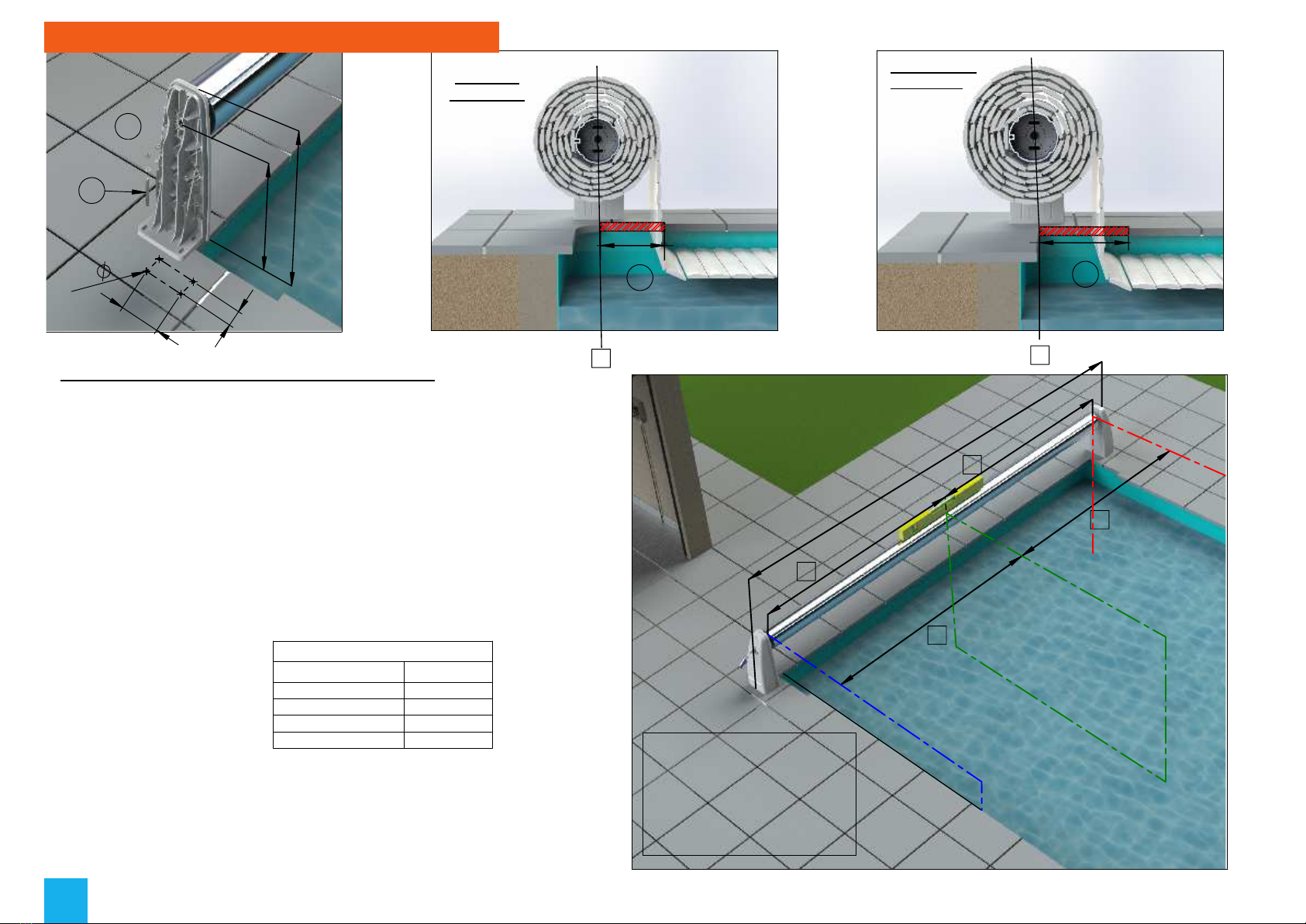

Preparation of coping stones in order to place the cover :

1) Position the stands assembled with the axle on the coping stones axis

according the below indications:

A) Respect the parallelism between the axle of unrolling slats and one of

the pool's length, as well as the axle leveling.

B) Please center the the cover on the pool's width, with stands close to the

aluminium profile. (otherwise, please plan to tighten the ring to prevent any

lateral play)

C) Axle at the base:

- of the coping stone if straight angled pool and coping

- of the en of the radius if rounded pool and coping

2

)

Fix the brackets with M10 knock-in studs through the coping

stones.

3

)

Cutting of the coping stones in line with the axis over a length Dm

according to the table opposite:

4

)

After mounting the cover, make sure that there is no friction when

opening and closing it (rear curbstone, side curbstone, skimmer, etc.).

Option: Surface a flat surface for the supports. Minimum dimension:

235 x 155 mm

2

1

390mm

499mm

If coping stone right angled

If rounded coping stone

Dm

3

Dm

3

CC

Width/2 Width/2

0° 0°

A

A

B

B

Pool lefthand side

Plan middle of pool cover

Pool righthand side

Width X

Width X = pool width + 440 mm

Axle: about 5 cm longer than the pool width

Coping stones

Pool length

Dm

6 m

260 mm

8 m

290 mm

10 m

320 mm

12 m

340 mm

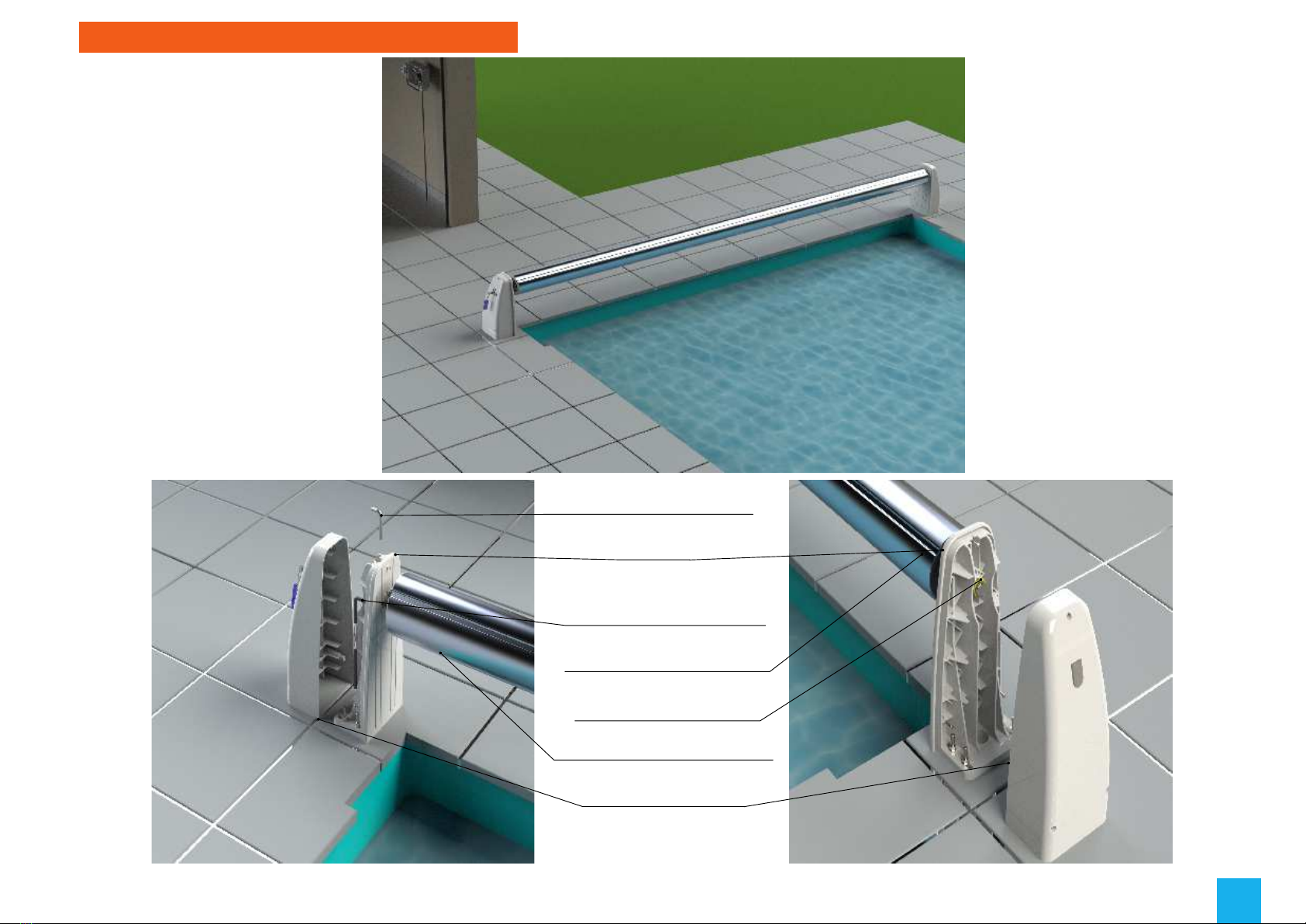

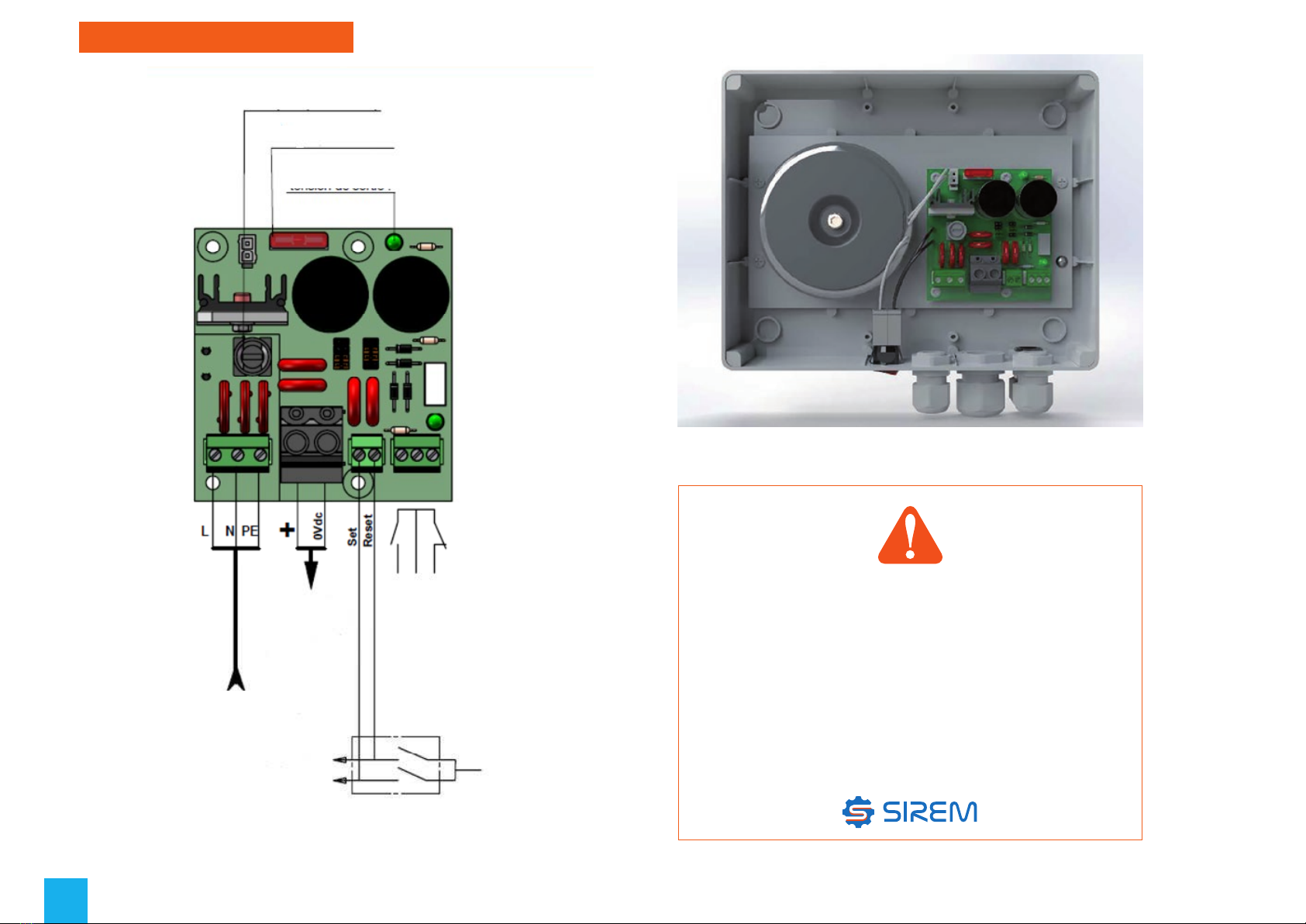

Installation of the power reel system6