List of Figures 20

4-11 Display Calibration Graphs Dialog Box..........................................67

4-12 Calibrate Window Showing ZQ-4000 Calibration Graphs..............69

5-1 Rotary Pump Assembly Fitted with Oil Mist Filter..........................76

5-2 Rotary Pump Oil Filler Plug, Drain Plug, and Sight Glass.............77

5-3 Isolation Valve................................................................................79

5-4 Oil Mist Filter Assembly.................................................................80

5-5 Pumping Block Assembly ..............................................................82

5-6 Ion Block Assembly .......................................................................83

5-7 Probe Assembly in Position on the Source....................................84

5-8 ZQ Detector Front View.................................................................85

5-9 Source Showing the Corona Discharge Needle ............................86

5-10 Ion Block........................................................................................86

5-11 Sample Cone and Cone Gas Nozzle.............................................87

5-12 Ion Block Rear View ......................................................................88

5-13 Hexapole Assembly.......................................................................89

5-14 Ion Block Cartridge Heater............................................................92

5-15 Replacing the Heater Cartridge.....................................................93

5-16 ESI Probe Tip with Capillary Protruding 0.5 mm...........................95

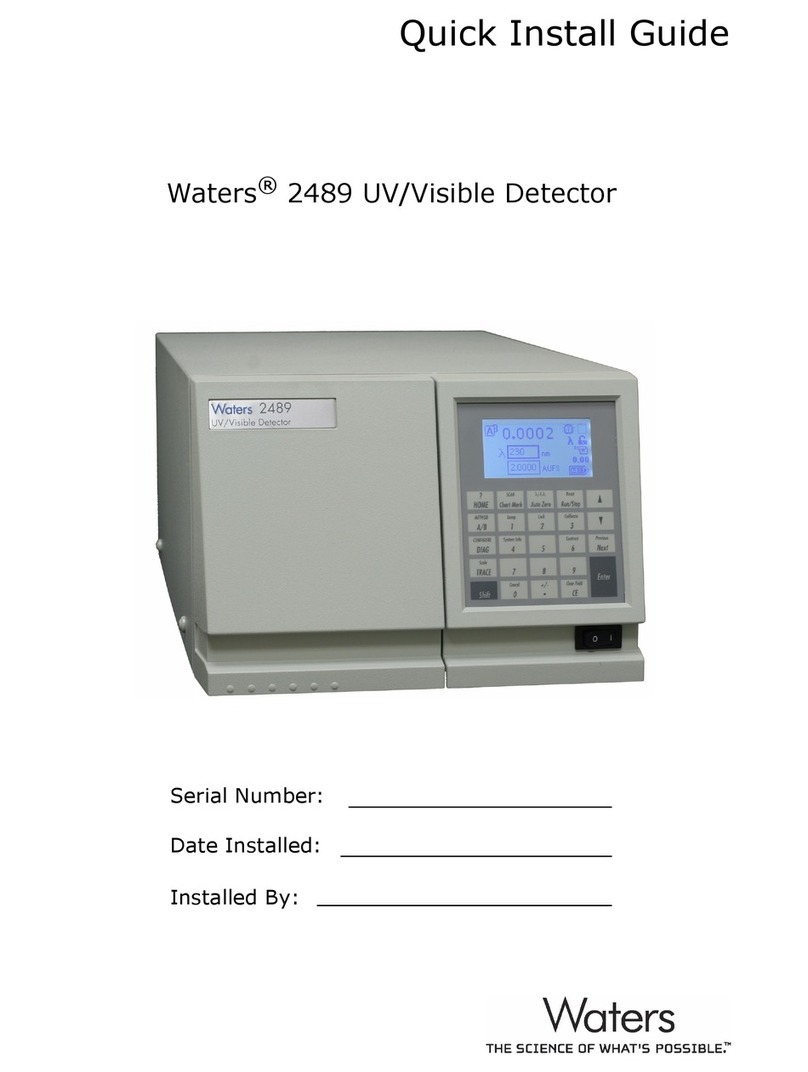

A-1 ZQ Mass Detector, Front View ...................................................109

A-2 Installing the Corona Needle ...................................................... 110

A-3 Tune Window .............................................................................. 110

A-4 Tune Window Showing Options List with ESCi Mode Selected . 111

A-5 Tune Window, Diagnostics Page ................................................ 112

A-6 Selecting the ESCi+ or ESCi- Ionization Mode ........................... 112

A-7 Selecting the Ion Mode in the MassLynx Peak Editor ................ 113

A-8 Tune Window as it Appears During ESCi Operation .................. 114

A-9 Function List Editor Window (Blank) ...........................................115

A-10 Function:nMS Scan Dialog Box ................................................. 115

A-11 Function List Editor Window Showing Specified Functions ........ 116

A-12 ESCi Mode Disabled ................................................................... 117

A-13 Daidzein (m/z = 255.2 [M + H] and 253.2 [M – H]) .....................117