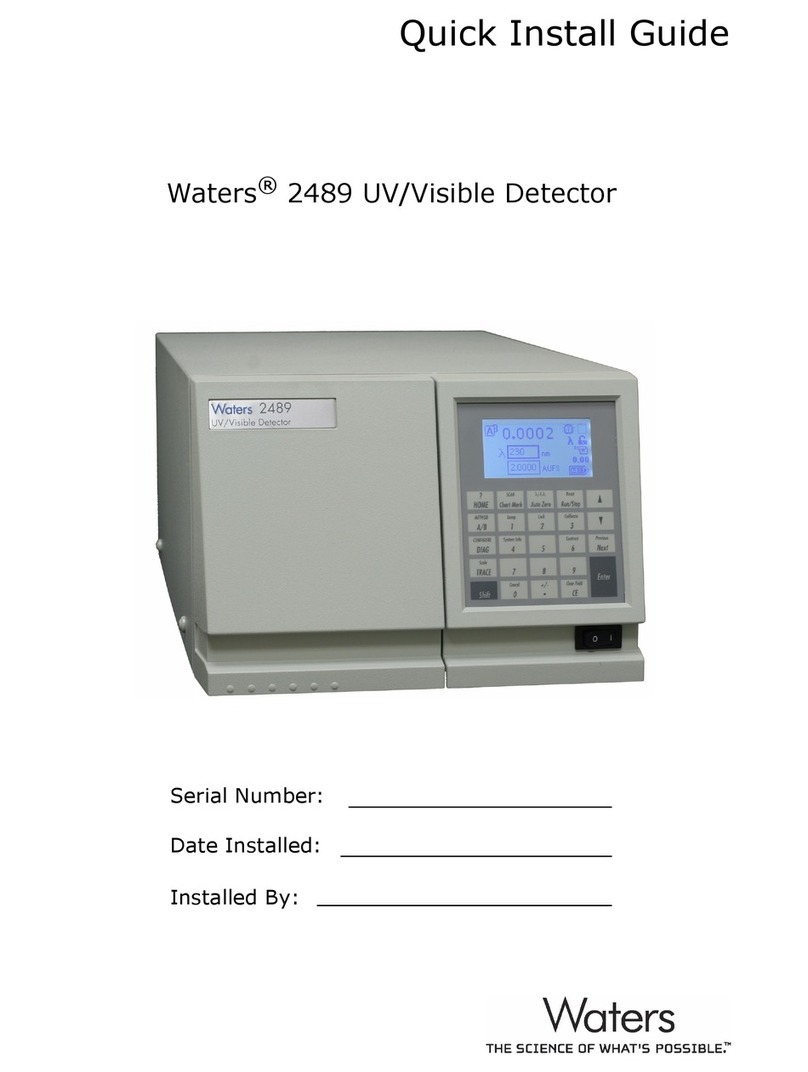

Waters 2489 Operating manual

Other manuals for 2489

3

Table of contents

Other Waters Security Sensor manuals

Waters

Waters ACQUITY Operating manual

Waters

Waters ACQUITY ELS User manual

Waters

Waters 2998 Operating manual

Waters

Waters ACQUITY RDa Operating manual

Waters

Waters 2489 Manual

Waters

Waters 3100 Manual

Waters

Waters Micromass ZQ 2000 Manual

Waters

Waters 2465 User manual

Waters

Waters 432 Manual

Waters

Waters 2487 Dual A Manual

Waters

Waters TQ Detector User manual

Waters

Waters 2489 Manual

Waters

Waters 2998 Manual

Waters

Waters ACQUITY QDa Operating manual

Waters

Waters 2487 User manual

Waters

Waters ACQUITY UPC2 Operating manual

Waters

Waters ACQUITY UPLC Operating manual

Waters

Waters 2475 Manual

Waters

Waters 2996 Manual

Waters

Waters 2414 Operating manual

Popular Security Sensor manuals by other brands

Saxby Lighting

Saxby Lighting 95283 instruction manual

ELRO

ELRO AS90MA manual

Optex

Optex FlipX Series installation instructions

Rigel

Rigel AFS101COMKISDFe instruction manual

Thermo Scientific

Thermo Scientific Dionex UltiMate 3000 Series operating instructions

walraven

walraven Pacifyre EFC Assembly instructions