Waters 2998 Manual

2998 Photodiode Array

Detector

Operator’s Guide

71500121902/Revision C

Copyright © Waters Corporation 2010

All rights reserved

ii

Copyright notice

© 2010 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF

AMERICA AND IN IRELAND. ALL RIGHTS RESERVED. THIS

DOCUMENT OR PARTS THEREOF MAY NOT BE REPRODUCED IN ANY

FORM WITHOUT THE WRITTEN PERMISSION OF THE PUBLISHER.

The information in this document is subject to change without notice and

should not be construed as a commitment by Waters Corporation. Waters

Corporation assumes no responsibility for any errors that may appear in this

document. This document is believed to be complete and accurate at the time

of publication. In no event shall Waters Corporation be liable for incidental or

consequential damages in connection with, or arising from, its use.

Trademarks

Waters and Alliance are registered trademarks of Waters Corporation, and

Empower, MassLynx, SAT/IN, TaperSlit, and “THE SCIENCE OF WHAT’S

POSSIBLE.” are trademarks of Waters Corporation.

Tygon is a registered trademark of Saint-Gobain Ceramics & Plastics, Inc.

Other registered trademarks or trademarks are the sole property of their

owners.

iii

Customer comments

Waters’ Technical Communications department invites you to tell us of any

errors you encounter in this document or to suggest ideas for otherwise

improving it. Please help us better understand what you expect from our

documentation so that we can continuously improve its accuracy and

usability.

We seriously consider every customer comment we receive. You can reach us

Contacting Waters

Contact Waters®with enhancement requests or technical questions regarding

the use, transportation, removal, or disposal of any Waters product. You can

reach us via the Internet, telephone, or conventional mail.

Safety considerations

Some reagents and samples used with Waters instruments and devices can

pose chemical, biological, and radiological hazards. You must know the

potentially hazardous effects of all substances you work with. Always follow

Waters contact information

Contacting medium Information

Internet The Waters Web site includes contact

information for Waters locations worldwide.

Visit www.waters.com.

Telephone and fax From the USA or Canada, phone 800

252-HPLC, or fax 508 872 1990.

For other locations worldwide, phone and fax

numbers appear in the Waters Web site.

Conventional mail Waters Corporation

34 Maple Street

Milford, MA 01757

USA

iv

Good Laboratory Practice, and consult your organization’s safety

representative for guidance.

Safety advisories

Consult Appendix A for a comprehensive list of warning and caution

advisories.

Operating this instrument

When operating this instrument, follow standard quality-control (QC)

procedures and the guidelines presented in this section.

Applicable symbols

Audience and purpose

This guide is intended for personnel who install, operate, and maintain the

Waters 2998 Photodiode Array (PDA) detector.

Symbol Definition

Manufacturer

Authorized representative of the European

Community

Confirms that a manufactured product complies

with all applicable European Community

directives

Australia C-Tick EMC Compliant

Confirms that a manufactured product complies

with all applicable United States and Canadian

safety requirements

Consult instructions for use

v

Intended use of the 2998 Photodiode Array detector

Waters designed the 2998 Photodiode Array detector to analyze and monitor

various types of compounds. The 2998 PDA detector is for research use only.

Calibrating

To calibrate LC systems, follow acceptable calibration methods using at least

five standards to generate a standard curve. The concentration range for

standards should include the entire range of QC samples, typical specimens,

and atypical specimens.

When calibrating mass spectrometers, consult the calibration section of the

operator’s guide for the instrument you are calibrating. In cases where an

overview and maintenance guide, not operator’s guide, accompanies the

instrument, consult the instrument’s online Help system for calibration

instructions.

Quality-control

Routinely run three QC samples that represent subnormal, normal, and

above-normal levels of a compound. Ensure that QC sample results fall within

an acceptable range, and evaluate precision from day to day and run to run.

Data collected when QC samples are out of range might not be valid. Do not

report these data until you are certain that the instrument performs

satisfactorily.

ISM classification

ISM Classification: ISM Group 1 Class B

This classification has been assigned in accordance with CISPR 11 Industrial

Scientific and Medical (ISM) instruments requirements. Group 1 products

apply to intentionally generated and/or used conductively coupled

radio-frequency energy that is necessary for the internal functioning of the

equipment. Class B products are suitable for use in both commercial and

residential locations and can be directly connected to a low voltage,

power-supply network.

vi

EC authorized representative

Waters Corporation (Micromass UK Ltd.)

Floats Road

Wythenshawe

Manchester M23 9LZ

United Kingdom

Telephone: +44-161-946-2400

Fax: +44-161-946-2480

Contact: Quality manager

Table of Contents vii

Copyright notice ................................................................................................... ii

Trademarks ............................................................................................................ ii

Customer comments ............................................................................................ iii

Contacting Waters ............................................................................................... iii

Safety considerations .......................................................................................... iii

Safety advisories................................................................................................. iv

Operating this instrument ................................................................................. iv

Applicable symbols ............................................................................................. iv

Audience and purpose......................................................................................... iv

Intended use of the 2998 Photodiode Array detector......................................... v

Calibrating ........................................................................................................... v

Quality-control ..................................................................................................... v

ISM classification .................................................................................................. v

ISM Classification: ISM Group 1 Class B .......................................................... v

EC authorized representative ........................................................................... vi

1 2998 PDA Detector Optics Principles ................................................ 1-1

Detector optics ................................................................................................... 1-2

Calculating absorbance ................................................................................... 1-3

Flow cell operating principles ....................................................................... 1-4

Resolving spectral data ................................................................................... 1-5

Measuring light at the photodiode array .................................................... 1-6

Optimizing the signal-to-noise ratio ............................................................... 1-7

Optimizing filter constants ............................................................................. 1-7

Selecting the appropriate sampling rate ........................................................ 1-7

Computing absorbance data points .............................................................. 1-9

Dark current .................................................................................................... 1-9

Table of Contents

viii Table of Contents

Reference spectrum ......................................................................................... 1-9

Data averaging................................................................................................. 1-9

Filtering data ................................................................................................. 1-12

Reference wavelength compensation............................................................ 1-13

2 Setting Up the Detector ........................................................................ 2-1

Before you begin ............................................................................................... 2-2

Unpacking and inspecting .............................................................................. 2-2

Laboratory site selection ................................................................................ 2-3

Detector dimensions ........................................................................................ 2-4

Connecting to the electricity source ............................................................ 2-4

Making signal connections ............................................................................. 2-5

Connecting the Ethernet cable........................................................................ 2-6

Network installation guidelines...................................................................... 2-7

Connecting to other instruments .................................................................... 2-8

Plumbing the detector ................................................................................... 2-16

Making the gas supply connection................................................................ 2-18

Starting up and shutting down the detector ............................................ 2-18

Starting up the detector ................................................................................ 2-19

Monitoring detector LEDs............................................................................. 2-20

Shutting down the detector........................................................................... 2-21

Using a cuvette ................................................................................................ 2-21

3 Maintaining the Detector ..................................................................... 3-1

Contacting Waters technical service ............................................................ 3-2

Maintenance considerations .......................................................................... 3-2

Safety and handling......................................................................................... 3-2

Spare parts....................................................................................................... 3-3

Routine Maintenance ....................................................................................... 3-3

Maintaining the flow cell ................................................................................ 3-4

Flushing the flow cell....................................................................................... 3-4

Table of Contents ix

Replacing the flow cell..................................................................................... 3-5

Replacing the lamp ........................................................................................... 3-7

Replacing the fuses ......................................................................................... 3-10

4 Diagnostic Tests and Troubleshooting ............................................. 4-1

Diagnostic tests ................................................................................................. 4-2

Verifying detector calibration ......................................................................... 4-2

Reading lamp energy ....................................................................................... 4-3

Performing the erbium calibration ................................................................. 4-3

Reading the calibration constants .................................................................. 4-4

Displaying PDA detector rear panel interface connections........................... 4-4

Changing the rear panel interface connections.............................................. 4-5

General troubleshooting ................................................................................. 4-6

Power surges .................................................................................................... 4-6

Clearing bubbles from the flow cell ................................................................ 4-7

Detector troubleshooting ................................................................................. 4-7

5 Spectral Contrast Theory ..................................................................... 5-1

Comparing absorbance spectra ..................................................................... 5-2

Representing spectra as vectors ................................................................... 5-2

Vectors derived from two wavelengths........................................................... 5-3

Vectors derived from multiple wavelengths................................................... 5-4

Spectral contrast angles .................................................................................. 5-4

Undesirable effects ........................................................................................... 5-7

Detector noise................................................................................................... 5-8

Photometric error............................................................................................. 5-8

Solvent changes ............................................................................................... 5-8

Threshold angle ............................................................................................... 5-8

A Safety Advisories .................................................................................. A-1

Warning symbols ............................................................................................... A-2

Task-specific hazard warnings........................................................................ A-2

Specific warnings ............................................................................................. A-3

x Table of Contents

Caution symbol .................................................................................................. A-5

Warnings that apply to all Waters instruments ......................................... A-6

Electrical and handling symbols ................................................................. A-12

Electrical symbols .......................................................................................... A-12

Handling symbols .......................................................................................... A-13

B Specifications ........................................................................................ B-1

C Solvent Considerations ....................................................................... C-1

Introduction ...................................................................................................... C-2

Clean solvents .................................................................................................. C-2

Solvent quality ................................................................................................. C-2

Preparation checklist....................................................................................... C-2

Water ................................................................................................................ C-2

Using buffers.................................................................................................... C-2

Tetrahydrofuran .............................................................................................. C-3

Solvent miscibility ........................................................................................... C-3

How to use miscibility numbers...................................................................... C-5

Buffered solvents ............................................................................................. C-6

Head height ....................................................................................................... C-6

Minimum tubing bend radius recommendations ..................................... C-6

Solvent viscosity ............................................................................................... C-7

Mobile phase solvent degassing ................................................................... C-7

Gas solubility ................................................................................................... C-7

Solvent degassing methods ............................................................................ C-8

Sparging ........................................................................................................... C-9

Vacuum degassing ........................................................................................... C-9

Solvent degassing considerations ................................................................... C-9

Wavelength selection .................................................................................... C-10

UV cutoffs for common solvents.................................................................... C-10

Mixed mobile phases...................................................................................... C-12

Table of Contents xi

Wavelength selection for chromophore detection......................................... C-13

Mobile phase absorbance............................................................................... C-14

Index ..................................................................................................... Index-1

xii Table of Contents

1-1

12998 PDA Detector Optics

Principles

To use the 2998 PDA detector effectively, you should understand the

principles that underlie operation of the detector’s optics and electronics.

Contents:

Topic Page

Detector optics 1-2

Flow cell operating principles 1-4

Resolving spectral data 1-5

Measuring light at the photodiode array 1-6

Computing absorbance data points 1-9

1-2 2998 PDA Detector Optics Principles

Detector optics

The detector is an ultraviolet/visible light (UV/Vis) spectrophotometer. With a

photodiode array of 512 photodiodes and an optical resolution of 1.2 nm, the

detector operates within a range of 190 to 800 nm.

The figure below illustrates the light path through the optics assembly of the

detector.

Optics assembly light path

The following table describes the optics assembly components.

Optics assembly components

Component Function

Lamp Deuterium source lamp.

M1 mirror Focuses light from the deuterium source lamp.

TP02819

Grating

Photodiode

array

Spectrograph

mirror and

mask

Flow cell

Window

Filter

flag/shutter

Lamp

Order filter

M1 mirror Slit

Detector optics 1-3

Calculating absorbance

The detector computes absorbance by subtracting the dark current (see “Dark

current” on page 1-9) from the reference spectrum (reference energy) and the

acquired spectrum (sample energy). Absorbance is based on the principles of

Beer’s law.

Beer’s law

The Beer-Lambert law (commonly called Beer’s law) describes the

relationship between the quantity of light of a particular wavelength arriving

Window Used to help minimize air infiltration into the lamp

housing.

Filter flag/shutter Flag positions for measuring open (sample) and

blocked (dark) beam energies and a third for

wavelength verification.

Flow cell Houses the segment of the flow path (containing eluent

and sample) through which the polychromatic light

beam passes.

Spectrograph

mirror and mask

The mirror focuses light transmitted through the flow

cell onto the slit at the entrance to the spectrographic

portion of the optics. The mirror mask defines the size

of the beam at the grating.

Slit Determines wavelength resolution and intensity of

light striking the photodiodes. The width of the slit is

50 µm.

Grating Disperses light into bands of wavelengths and focuses

them onto the plane of the photodiode array.

Order filter Reduces the contribution of second-order diffraction of

UV light (less than 370 nm) to the light intensity

observed at visible wavelengths (greater than 370).

Photodiode array A linear array of 512 photodiodes. The diode width

(50 µm), together with a 50-µm slit, yields single

wavelength resolution of 1.2 nm.

Optics assembly components (Continued)

Component Function

1-4 2998 PDA Detector Optics Principles

at the photodiode and the concentration of the sample passing through the

flow cell. Beer’s law is expressed as A= εlc where

A= dimensionless quantity measured in absorbance units

ε = constant of proportionality known as the molar absorptivity

l= path length in centimeters (1.0 cm in the detector’s normal flow cell)

c= concentration in moles per liter

Beer’s law applies only to well-equilibrated dilute solutions. It assumes that

the refractive index of the sample remains constant, that the light is

monochromatic, and that no stray light reaches the detector element. As

concentration increases, the chemical and instrumental requirements of

Beer’s law are sometimes violated, resulting in a deviation from (absorbance

versus concentration) linearity. The absorbance of mobile phase can reduce

the linear range.

Absorbance as a function of concentration

Flow cell operating principles

The Waters TaperSlit™ flow cell used in the 2998 detector renders the

detector baseline essentially insensitive to changes in mobile phase refractive

index (RI). RI changes occur during gradient separations or result from

temperature or pump-induced pressure fluctuations.

To achieve RI immunity, a combination of a spherical mirror, a lens at the

entrance of the flow cell, and a taper to the internal bore of the flow cell

Concentration

Absorbance

Ideal

Actual

Linear range

for analyte

Resolving spectral data 1-5

prevents light rays from striking the internal walls of the flow cell. The

Waters TaperSlit flow cell, so-called because of the shape of the flow cell exit

face, matches the shape of the spectrograph slit. Compared to a conventional

flow cell with a cylindrical shape, the 2998 detector achieves higher light

throughput for a given spectral resolution with the TaperSlit cell design.

Comparison of flow cell characteristics

Resolving spectral data

Together with photodiode spacing, the detector’s 50-µm slit determines the

intensity and bandwidth of the light that strikes the photodiode array.

Reducing the bandwidth increases the resolving power of the detector. As a

result, similar spectra are more effectively distinguished.

The grating images the slit onto the photodiode array. The angle of diffraction

from the grating determines the wavelength that strikes a particular

photodiode in the array.

The following figure shows an absorbance spectrum of benzene. Note that the

wavelength resolution is sufficient to resolve five principal absorption peaks.

Window

Window

UV light

Conventional flow cell:

TaperSlit analytical flow cell:

Window

Lens

UV light

1-6 2998 PDA Detector Optics Principles

Benzene spectrum at different resolutions

Measuring light at the photodiode array

The detector measures the amount of light striking the photodiode array to

determine the absorbance of the sample in the flow cell.

The array consists of a row of 512 photodiodes. Each photodiode acts as a

capacitor initially holding a fixed amount of charge.

Light striking a photodiode discharges the diode. The magnitude of the

discharge depends on the amount of light striking the photodiode.

Absorbance

nm

230.00 250.00 270.00

1.2 nm

3.6 nm

Measuring light at the photodiode array 1-7

Photodiodes discharged by light

The detector measures the amount of charge required to recharge each

photodiode. The charge is proportional to the amount of light transmitted

through the flow cell over the interval specified by the diode exposure time.

Optimizing the signal-to-noise ratio

To optimize signal-to-noise ratios, choose an acquisition wavelength range

that includes only the wavelengths of interest. Ensure that the range is one in

which the mobile phase absorbs only minimally (see Appendix C). You can

further improve the signal-to-noise ratio by increasing the bandwidth

parameter. For example, you can choose to operate at 3.6 nm instead of at

1.2 nm resolution. See page 1-10 for more information.

Optimizing filter constants

The filtering constant you select affects the peak intensity. To increase

sensitivity, decrease the filter time constant.

Selecting the appropriate sampling rate

A sufficient number of points must fall across a peak to define its shape. Thus,

the definition between peaks is lost at very low sampling rates. Empower uses

Mirror

Grating

Flow cell

Deuterium lamp

Light from grating

dispersed onto

diodes.

Sample in flow cell

absorbs at specific

wavelengths.

Slit

1-8 2998 PDA Detector Optics Principles

the end time minus the start time, to calculate the Points Across Peak value

for each integrated peak in the chromatogram.

Tip: The Points Across Peak value appears in the Peaks table, at the bottom of

the Review Main window. If the Points Across Peak field is not visible,

right-click anywhere in the table, and then click Table Properties. Click the

Columns tab, and then scroll down to find the Points Across Peak field. Clear

the check box, and then click OK.

If the Points Across Peak value for the narrowest peak of interest is less than

25, you should specify a higher sampling rate in the instrument method. If the

value is greater than 50, you should specify a lower sampling rate in the

instrument method.

Example of how baseline noise increases with higher sampling rates

5 Hz

10 Hz

20 Hz

40 Hz

Other manuals for 2998

1

Table of contents

Other Waters Security Sensor manuals

Waters

Waters 2414 Operating manual

Waters

Waters 2465 User manual

Waters

Waters ACQUITY RDa Operating manual

Waters

Waters 3100 Manual

Waters

Waters ACQUITY UPLC Operating manual

Waters

Waters 2998 Operating manual

Waters

Waters TQ Detector User manual

Waters

Waters ACQUITY Operating manual

Waters

Waters ACQUITY QDa Operating manual

Waters

Waters 2996 Manual

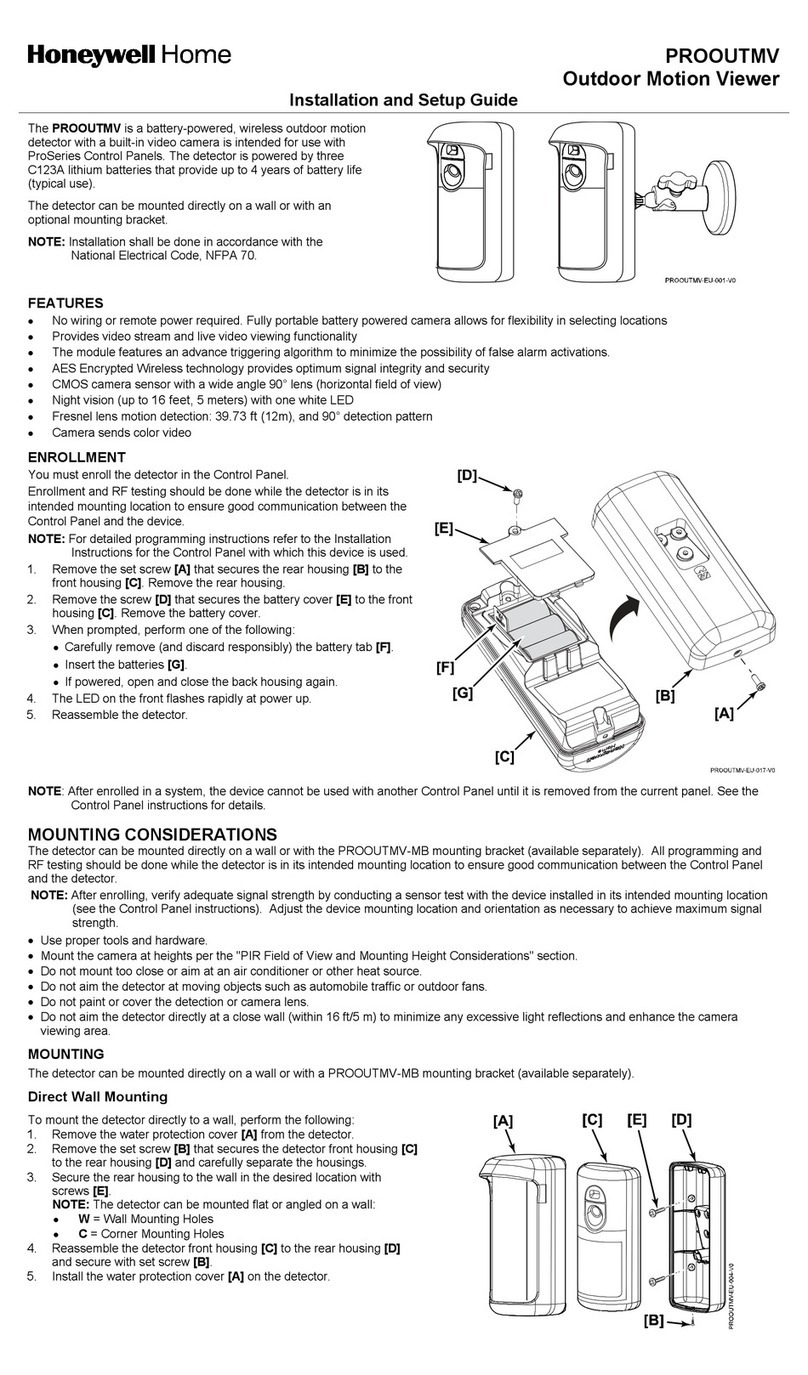

Popular Security Sensor manuals by other brands

resideo

resideo Honeywell Home PROOUTMV Installation and setup guide

ABB

ABB Orion3 Extended Excerpts from the original instructions

Permalert

Permalert PAL-AT Series operating instructions

Dräger

Dräger X-zone 5000 manual

Draminski

Draminski PREGNANCY DETECTOR manual

ESYLUX

ESYLUX PD 360/8 Basic Detailed operating instructions