x Table of Contents

Flow cell options ................................................................................................ 17

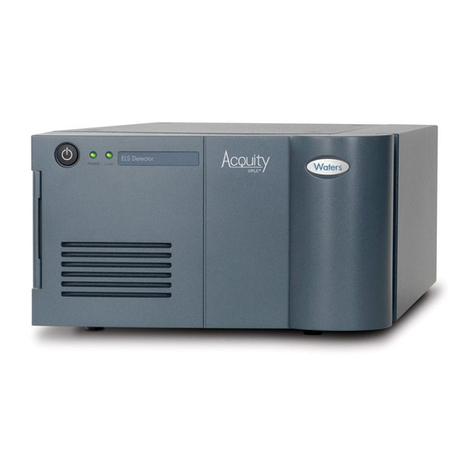

Before you begin ................................................................................................ 18

Installing the detector ...................................................................................... 19

Plumbing the detector ...................................................................................... 21

Installing the multi-detector drip tray ............................................................. 25

Making Ethernet connections ......................................................................... 27

I/O signal connector ........................................................................................... 27

Connecting to the electricity source ............................................................. 28

Starting the detector ......................................................................................... 29

Monitoring detector LEDs................................................................................. 31

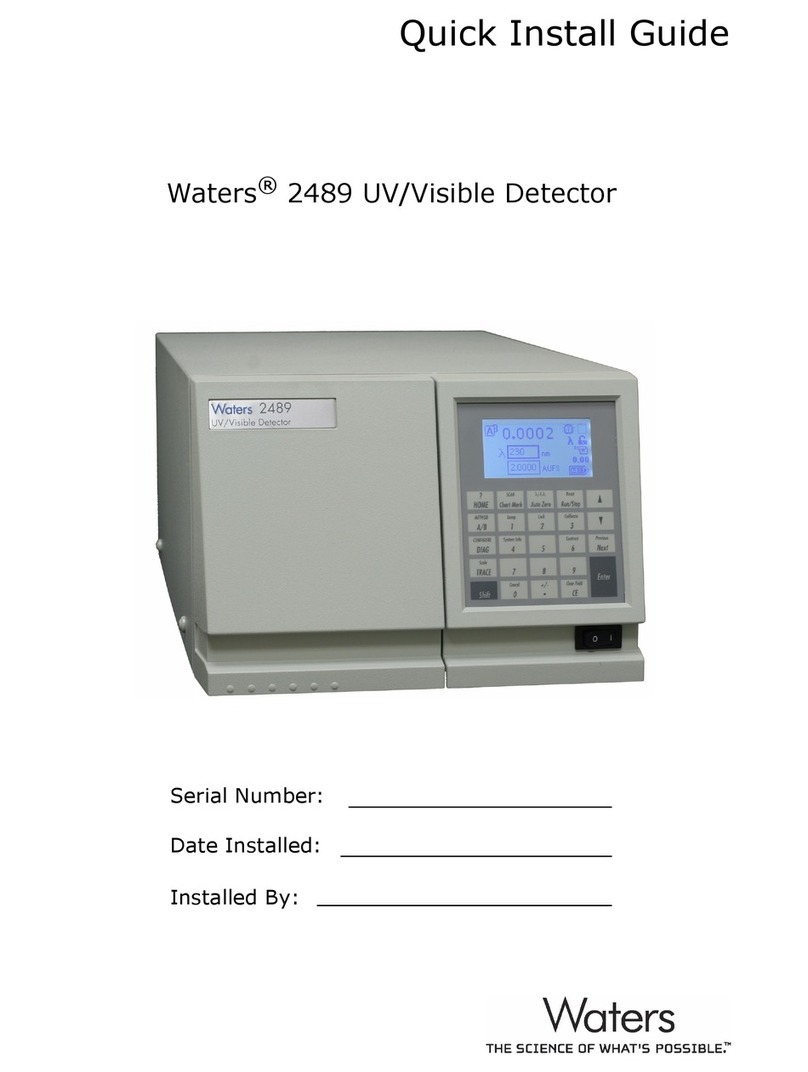

About the detector control panel....................................................................... 31

Shutting down the detector ............................................................................. 34

Shutting down for less than 24 hours............................................................... 34

Shutting down for more than 24 hours............................................................. 34

Maintaining the detector ................................................................................. 36

Contacting Waters technical service................................................................. 36

Maintenance considerations.............................................................................. 37

Proper operating procedures ............................................................................. 37

Maintaining the leak sensor ............................................................................. 39

Replacing the detector’s leak sensor................................................................. 43

Maintaining the flow cell................................................................................... 45

Replacing the lamp ............................................................................................ 56

Replacing the fuses ............................................................................................ 59

Cleaning the instrument’s exterior................................................................... 60

Spectral contrast theory .................................................................................. 61

Comparing absorbance spectra ......................................................................... 61

Representing spectra as vectors........................................................................ 62

Spectral contrast angles .................................................................................... 64

Undesirable effects ............................................................................................ 67

Error messages and troubleshooting ............................................................ 71

Startup error messages ..................................................................................... 71