B

The mechanical endstops should never be blocked

during the initial homing function or during a print.

Share ideas & collaborate:

Forum.LulzBot.com

Adjustment of the Z Axis

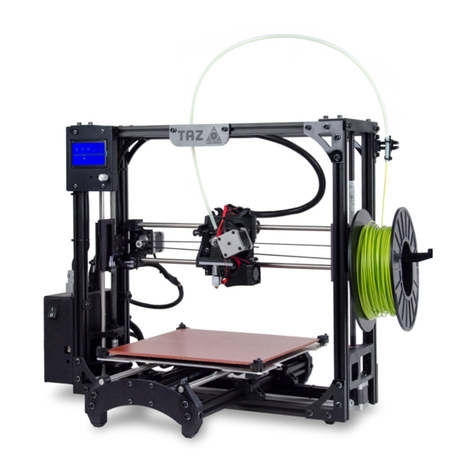

A

Take the time to go through the leveling

procedure to help ensure that your prints are

consistent and trouble free. Install Cura- our

recommneded print host software and connect

to the printer as described in the Cura software section

in the complete TAZ 3D printer manual. Use the homing

buttons to home the X and Y axis. When Cura is first

launched a model should be visible on the work plane. If

not, load a model (stl file) to control your 3D printer.

17

Do not use the

Home Z

button until after the Z a is

end stop has been adjusted. Also make sure you have

removed the red shipping clamps on the Z a is smooth

rods.

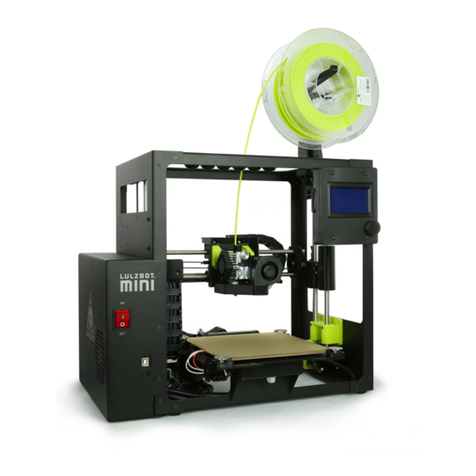

Raising the Z Axis

A

Use the

+Z 10

button to move the Z axis up

in 1 0mm increments. Raise the Z axis until the

hot end nozzle is approximately 40-50mm

away from the print bed.

18

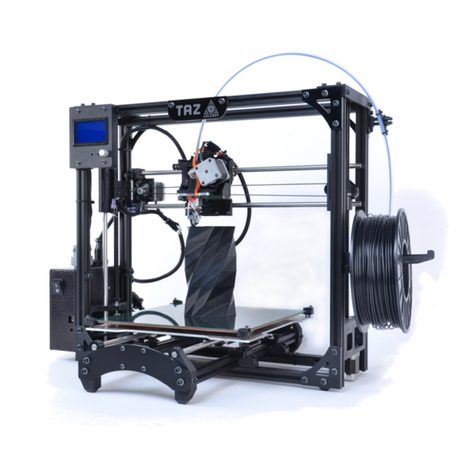

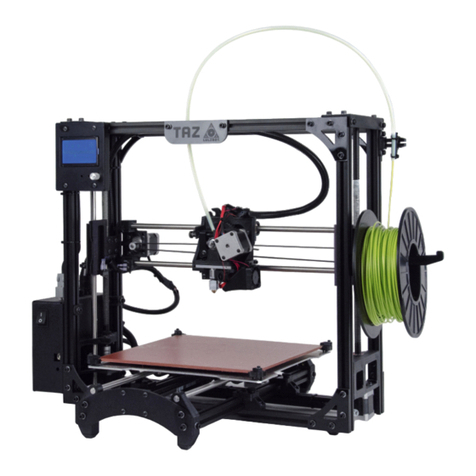

B con .

The

distance measurement

should be the same on

left and right. If not, in

Cura, turn off the stepper

motors by pressing the

mo ors Off

button.

Turn the threaded rod by

hand on one side of the

printer to raise or lower

that side to match the

measurement on the

other side.

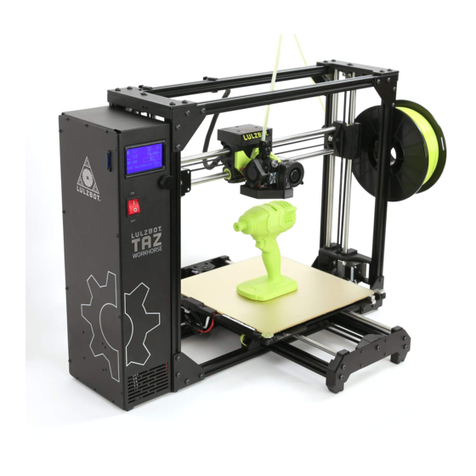

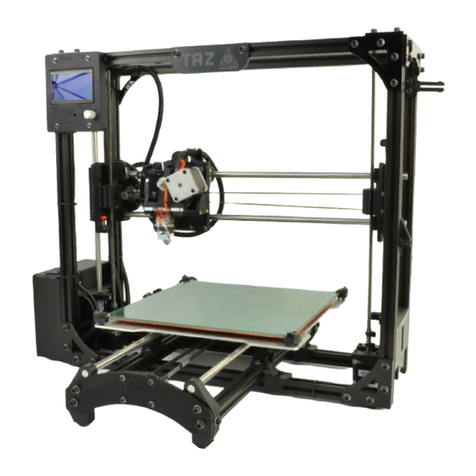

Fine Adjustment of the Z Axis End Stop

Rotate the endstop trigger clockwise to lower

the surface of the thumb-screw by roughly the

same amount as the distance between the

nozzle tip and the print surface. Press the

Home Z

button to home the Z axis. The tip of the

nozzle should now be very close to the surface of the

bed.

19

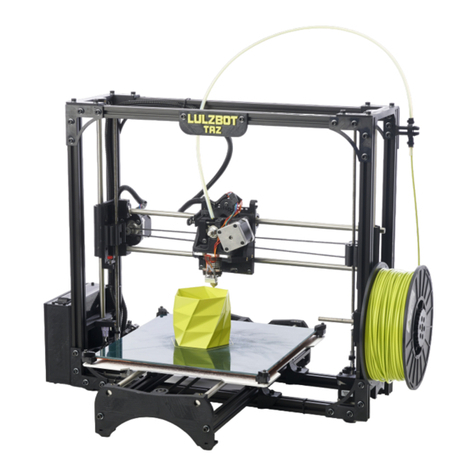

A

Slide a once-folded piece of paper

underneath the nozzle, adjust the Z axis end

stop trigger and home the Z axis through

Cura by pressing the

Home Z

button until

the tip of the nozzle applies pressure on the paper. You

should be able to slowly pull out the sheet of paper

with only slight resistance.

20

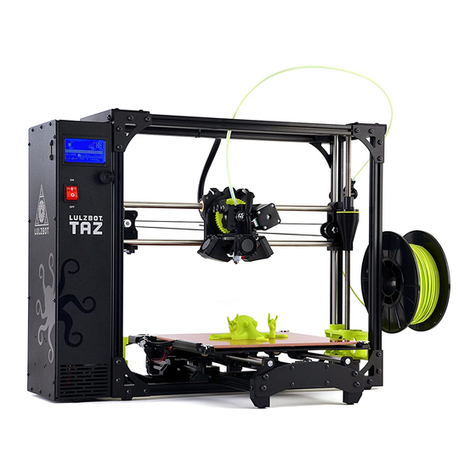

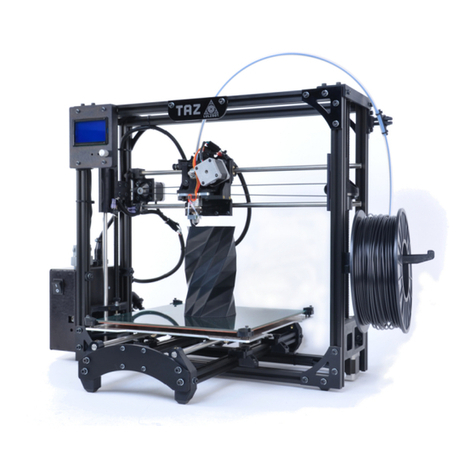

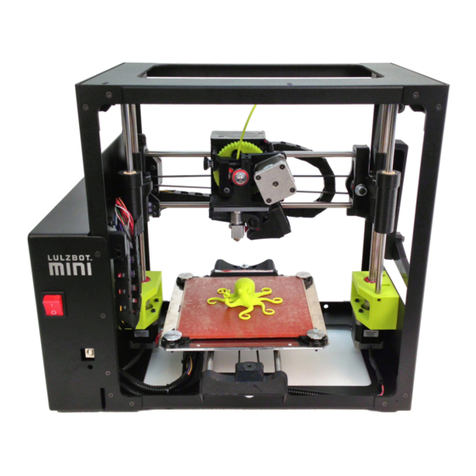

Leveling the Print Bed

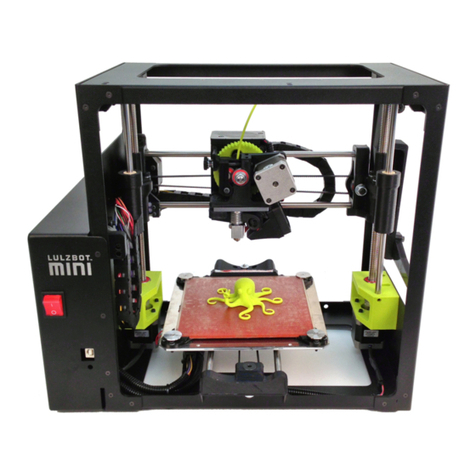

B

Move the hot end nozzle tip over to the far right

side of the X axis by using the

+X 100

button in Cura.

As the X axis carriage approaches the end of the Y axis,

use the

+X 10

button and the

+X 1

button until the tip

of the nozzle is near the front right corner of the bed.

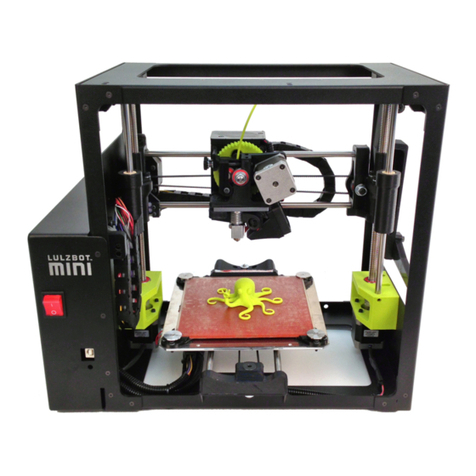

C

Slide the same piece of paper under the nozzle

and home the Z axis. Adjust that bed corner's bed

leveling scre s so that the tension felt hen

moving the paper under the nozzle matches the

tension felt previously. To raise or lo er the front

right corner of the bed, adjust only the scre ith

the spring. Turn the scre clock ise to lo er the

bed, decreasing the tension felt hen moving the

paper. Turn the scre counter-clock ise (raising

the corner) to increase the tension felt hen

moving the piece of paper under the nozzle. Once

adjusted, press the

+Z 10

button to raise the Z axis.

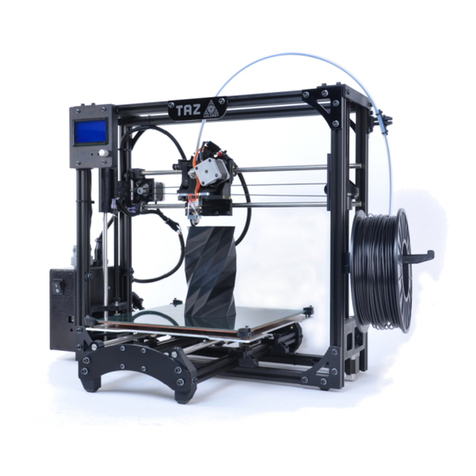

D

Repeat the same process, first raising the Z axis,

then using the

+y

button to move the heated bed to

place the nozzle on the rear right corner of the bed.

Adjust the height of the bed using the same procedure

as outlined above. Finally, raise the Z axis and move the

X axis carriage over to the rear left corner of the bed

and perform the same leveling procedure to adjust the

last corner. Close the Control window,

righ click

on the work plane and select

Dele e All

Objec s

.

B

With the Z axis above the bed, use the included

1 50mm ruler to measure the distance from the bottom

of the X axis smooth rod and the top surface of the Y

axis aluminum bed plate on the left side.

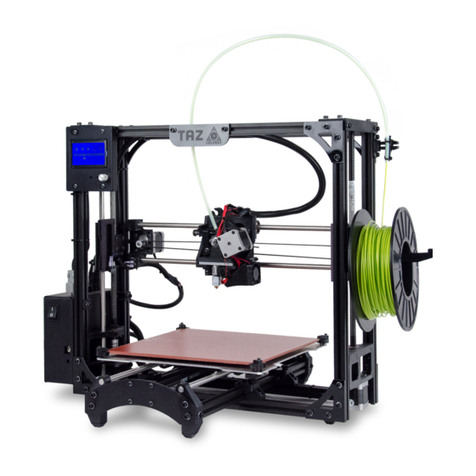

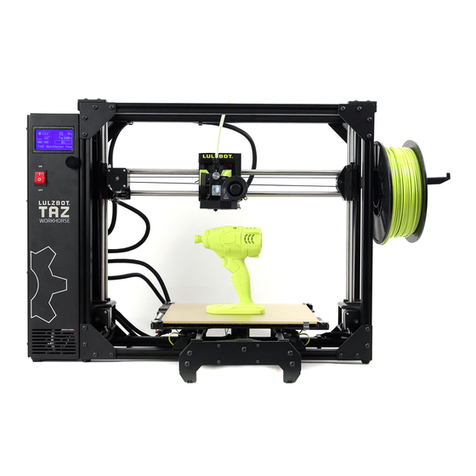

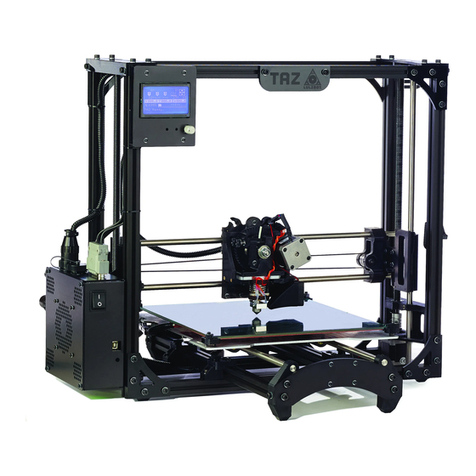

B

Once connected to the printer in Cura, rotate the Z

axis end stop trigger (mounted on the X-axis motor

mount) counter-clockwise to raise the thumb-screw

approximately 1 cm higher toward the Z axis end stop.

C

In Cura press the

Home Z

button to home the Z

axis. The hot end will lower to about a centimeter above

the heated bed. If there's a grinding sound, stop, turn the

printer off and check that the Z axis is level in relation to

the body of the printer (see 16b). Manually rotate one of

the Z axis linear threaded rods by hand if needed.

nex up:

Create your first 3D print