ENGLISH

SUMMARY - English

1. Safety Instructions .......................................................................................................................................03

2. What is the SSW-05 Plus Soft-Starter .........................................................................................................03

3. How to identify the SSW-05 Plus .................................................................................................................03

4.TechnicalData .............................................................................................................................................04

5. SSW-05 Plus Description ............................................................................................................................05

6.Table ofPowers/Currents/PowerWiring (copper wireat70°C(158oF)) ......................................................05

7.TableofConnectorTighteningTorque ...........................................................................................................05

8. Capacity of the Power Supply Line...............................................................................................................06

9. Table of Fuses and Contactors .....................................................................................................................06

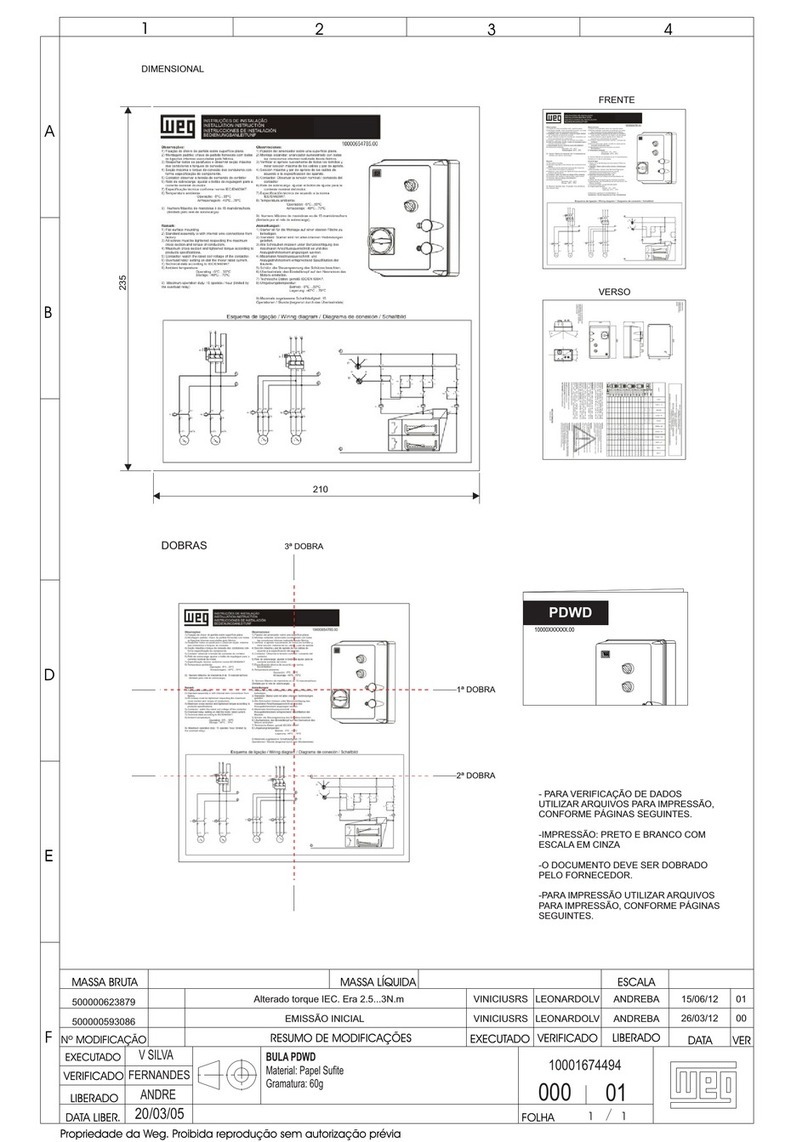

10.Dimensions ................................................................................................................................................06

11. SSW-05 Plus Installation and Connection ..................................................................................................07

12. SSW-05 Plus Setting .................................................................................................................................08

13.Operation of the DigitalRelayOutputs........................................................................................................10

14. Protections and Displays ...........................................................................................................................11

15.OverloadProtection ....................................................................................................................................12

16.Reset .........................................................................................................................................................13

17. Faults and Possibles Causes.....................................................................................................................13

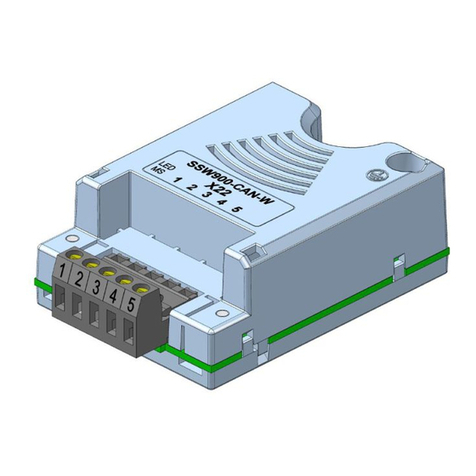

18.Solvingthemostfrequent problems ............................................................................................................15

19. SSW- Options andAccessories .................................................................................................................15

20.Table of Parameters (for serial communication/HMI-SSW05-RS) ................................................................20

21.Errorcode and description (for serialcommunication/HMI-SSW05-RS) ....................................................21

22.DetailedParameterDescription(forserialcommunication/HMI-SSW05-RS)...............................................21

23.AppendixforCE Conformance ....................................................................................................................28

24.EUDeclarationofConformity......................................................................................................................29

Warranty SSW-05 Plus....................................................................................................................................30