Shenzhen Weistek Technology Co., Ltd. www.weistek.net

4

Using Instructions and Important Safety Considerations

During printing process, do not touch power cable or USB cable, do not pull out SD card, or printing

will be stopped.

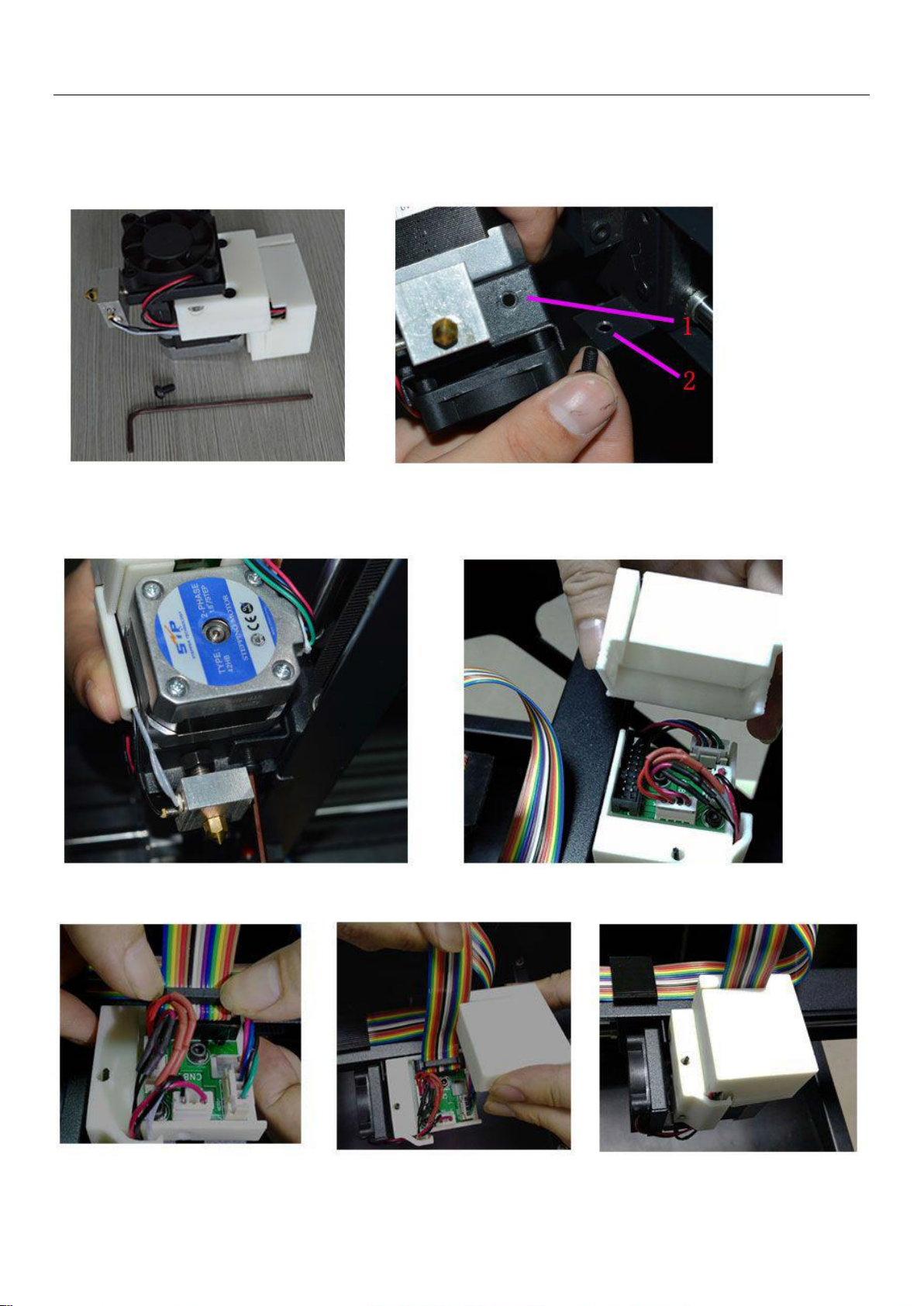

If extruder does not extrude, please do not heat it for long time, or nozzle may be blocked.

While testing printer, print filament will be extruded out from nozzle, please keep nozzle at least

50mm away from printing build bed, or nozzle may be blocked.

Please do not use the third party software to update firmwares of this printer, or printing can not

be conducted with the software provide by our company.

Please do not change parameter settings of printer, or printer may not work properly.

Please do not reach your hand onto build bed while heating or using extruder, or you may be hit

or burned by moving components.

Please do not put or use printer in dusty, highly humid or strong sunlight environment.

Please do not put printer on an inclining platform, or printing effect may be affected, printer may

fall, get damaged or break other things.

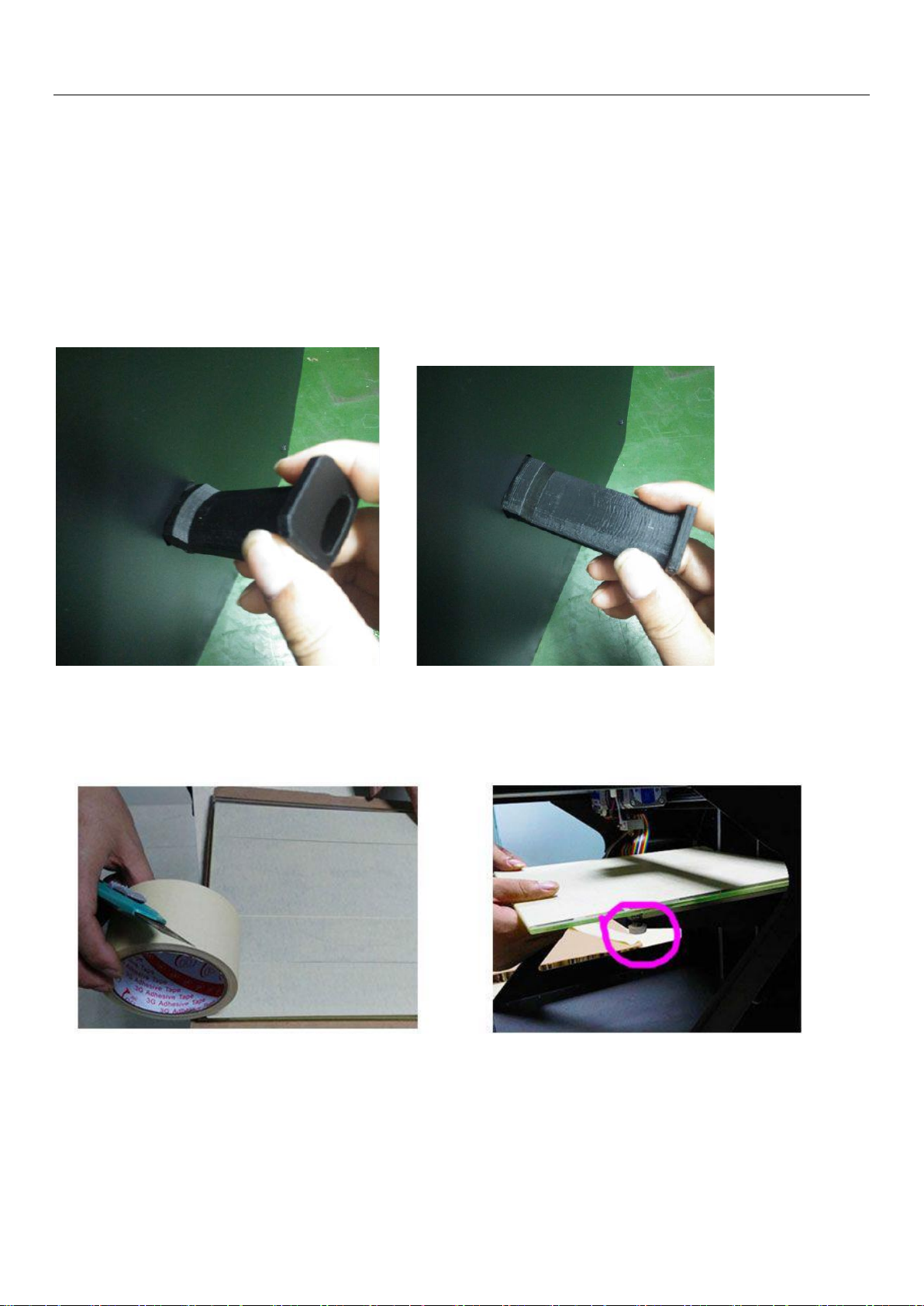

Please do not uninstall model from build bed without wearing protective gloves, or you may get

burned or scratched.