1. Introduction

105466 –TW-31-E - V1.9 - 06.04.2021 Page 3

6. Operation and fault handling....................................................................................................................30

6.1 Description of tank monitor operation.............................................................................................30

6.2 Milk removal YES or NO.................................................................................................................32

6.3 Handling multiple faults...................................................................................................................35

6.4 Display fault memory......................................................................................................................35

6.5 Listing fault memory and description..............................................................................................36

6.5.1 Critical tank monitor alarms (red).......................................................................................36

6.5.2 Informative tank monitor alarms (green)............................................................................37

6.5.3 System alarms...................................................................................................................38

6.5.4 System alarms external sensors........................................................................................39

6.5.5 Test alarm..........................................................................................................................39

7. Setting of parameters...............................................................................................................................41

7.1 GUIDELINE for the correct parameterization.................................................................................41

7.1.1 Enter customer and tank number ......................................................................................41

7.2 Change and save parameter values...............................................................................................42

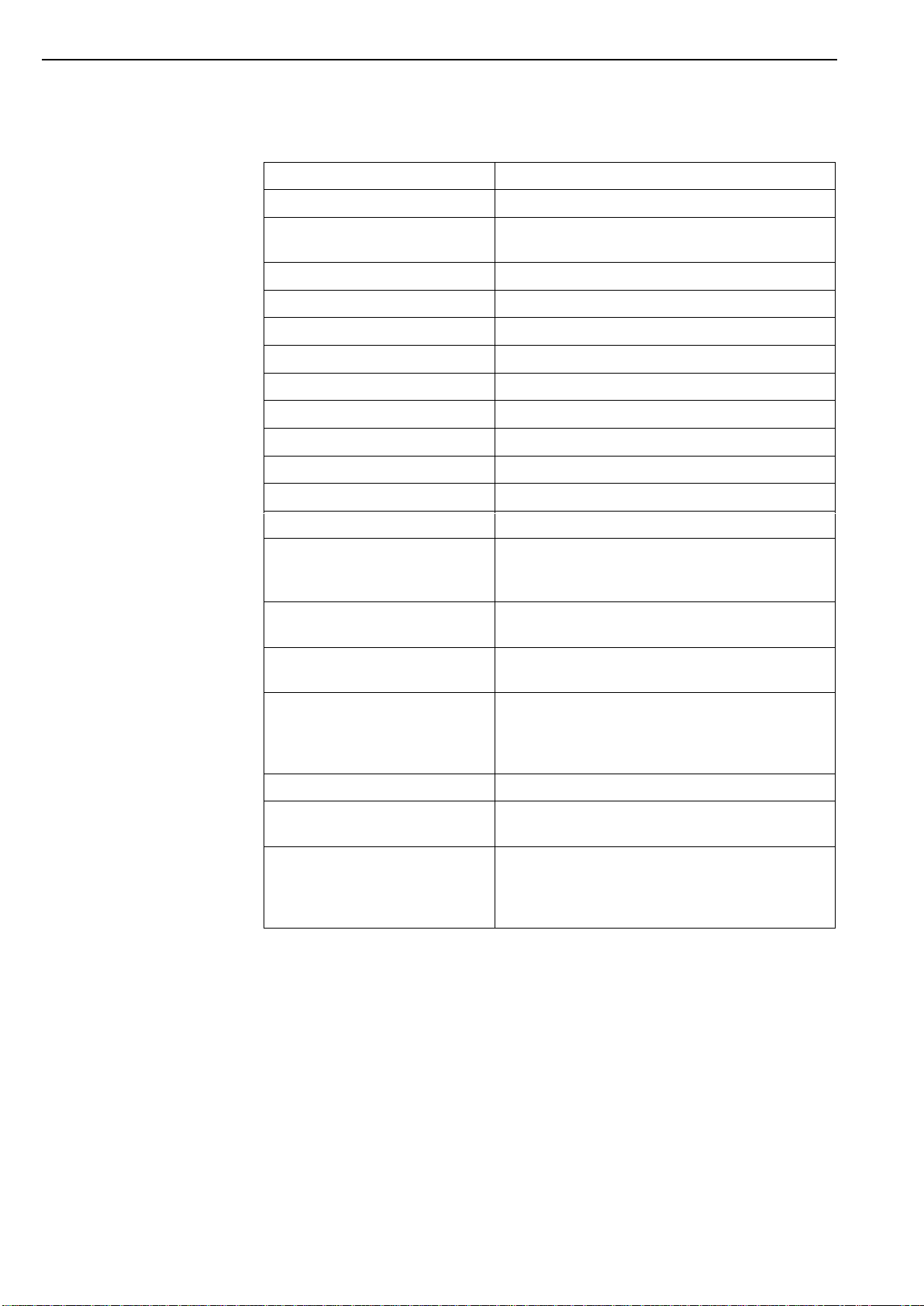

7.3 Level “General tank monitor parameters” (h parameters) ..........................................................44

7.4 Level “Extended tank monitor parameters” (H parameters) ..........................................................48

7.5 Level “Alarm - Event assignment” (F parameters) ..........................................................50

7.6 Level “Hardware configuration” (A- parameters).........................................................52

7.7 Level “Sensor adjustment“ (C- parameters).........................................................56

7.8 Level “Service parameters” (E- parameters).........................................................57

7.9 Ebene “I / O test parameters” (o- parameters).........................................................58

8. Other informations ...................................................................................................................................60

8.1 Detection of mode “cooling” - parameter [h1].................................................................................60

8.2 Safety function: “First milk in the tank” [h2] ....................................................................................60

8.3 Detection of mode “Cleaning” - parameter [h4]..............................................................................61

8.4 Definition of term “milk temperature too high for too long” .............................................................62

8.5 Definition of term “cooling time” + target temperature first milking”................................................62

8.6 Activation delay tank monitor [H90]................................................................................................63

8.7 Sensor correction procedure ..........................................................................................................63

8.8 Function second temperature sensor.............................................................................................64

8.9 Setting of the level control ..............................................................................................................64

8.10 Monitoring of detergent dispenser..................................................................................................64

8.11 Function power pack + regular exchange ......................................................................................65

8.12 Monitoring of detergent dispenser..................................................................................................66

8.12.1 Cancellation of the recorded temperatures in the diagram................................................67

8.13 Test functions .................................................................................................................................67

8.13.1 Test alarm F99...................................................................................................................67

8.13.2 Function test "Do-Not-Load LED" and "external alarm light".............................................67

8.14 General measures when using electronic control systems............................................................68

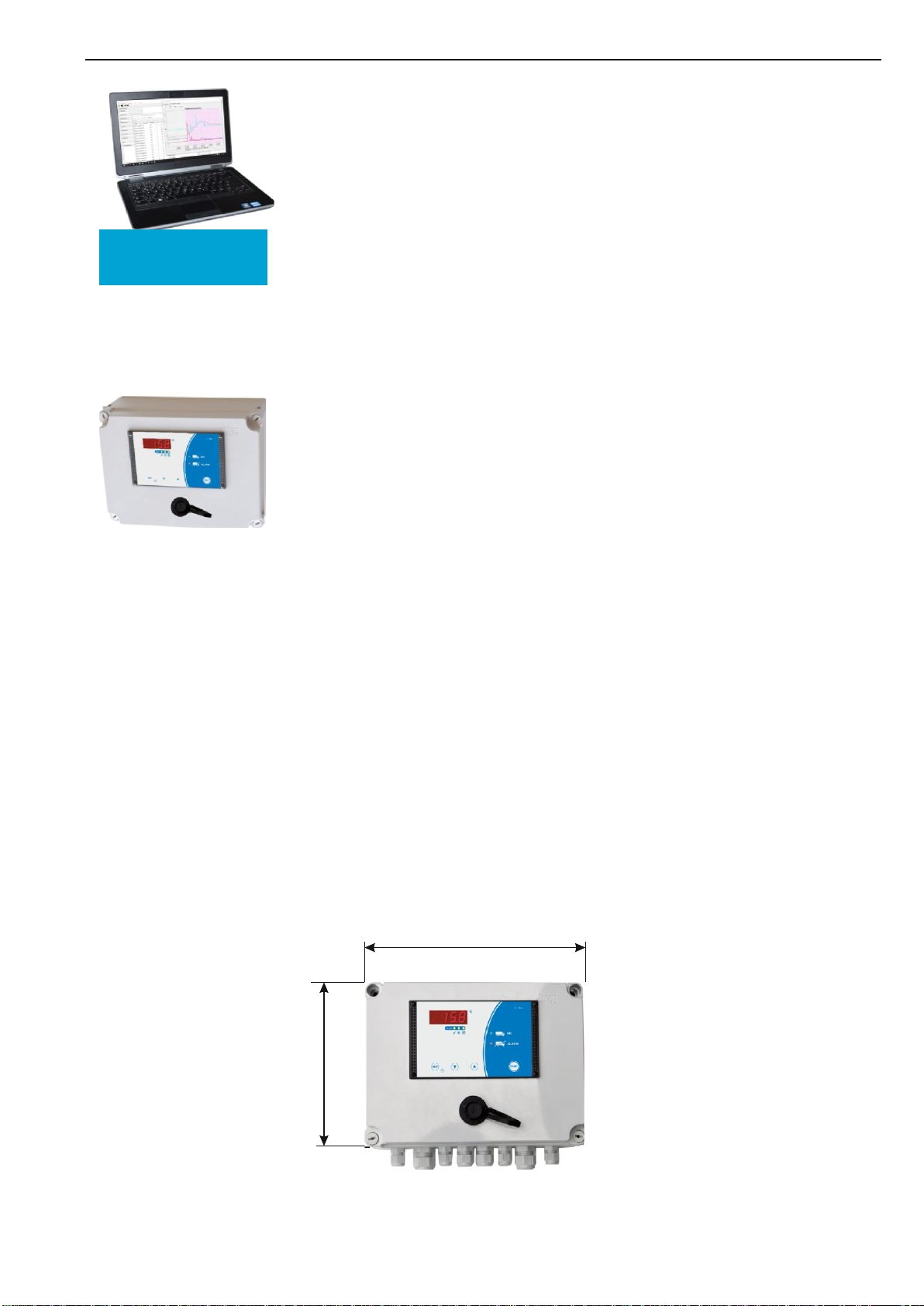

Publisher:

Welba GmbH

Electronic Control Engineering

Gewerbepark Siebenmorgen 6

D-53547 Breitscheid

+49 (0)2638 / 9320-0

+49 (0)2638 / 9320-20

info@welba.de

www.welba.de