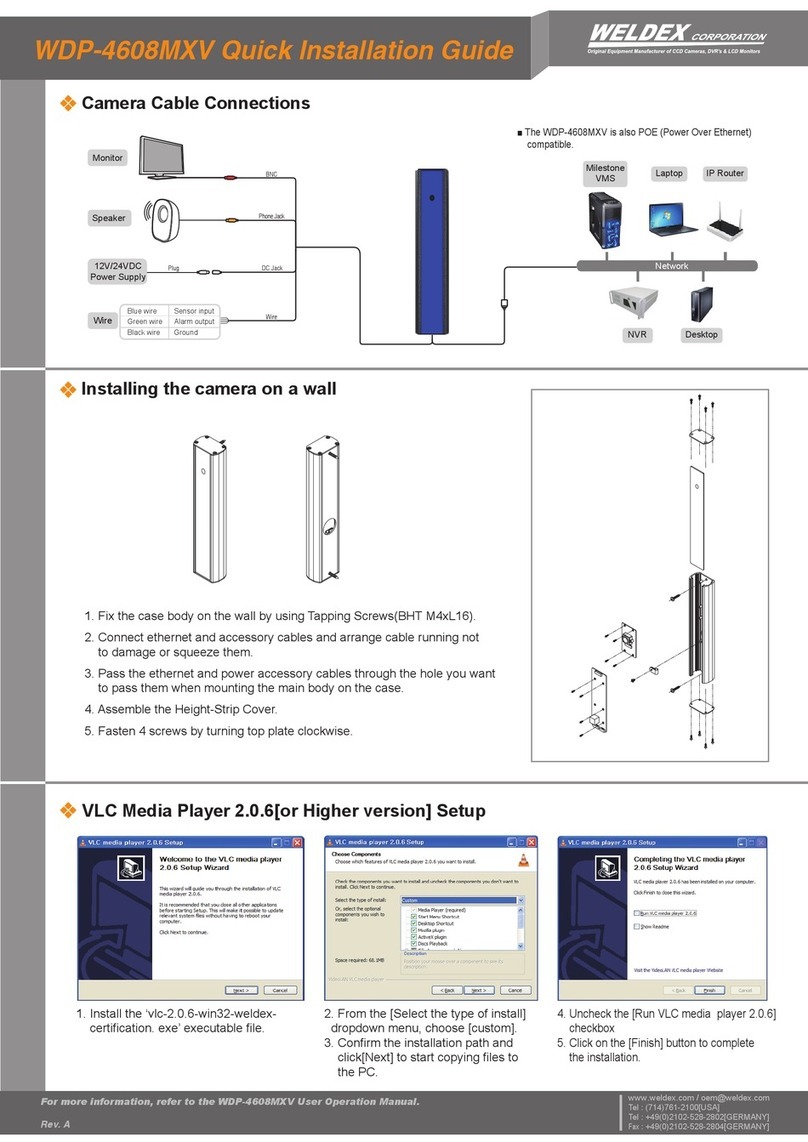

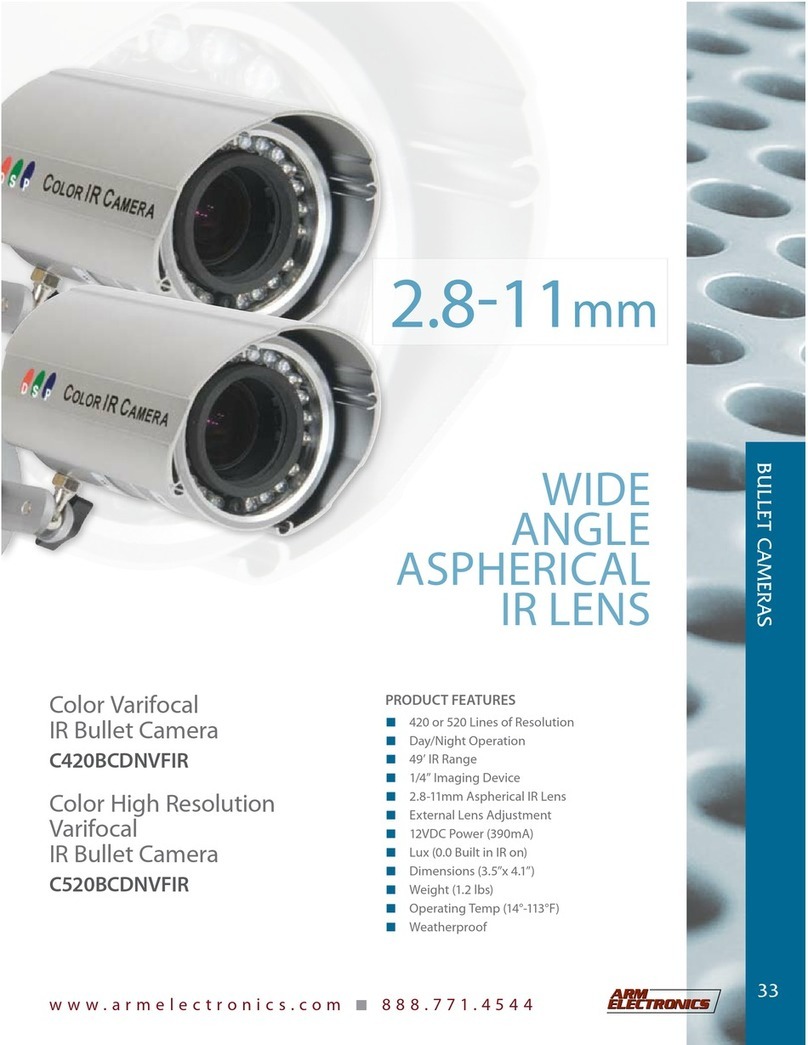

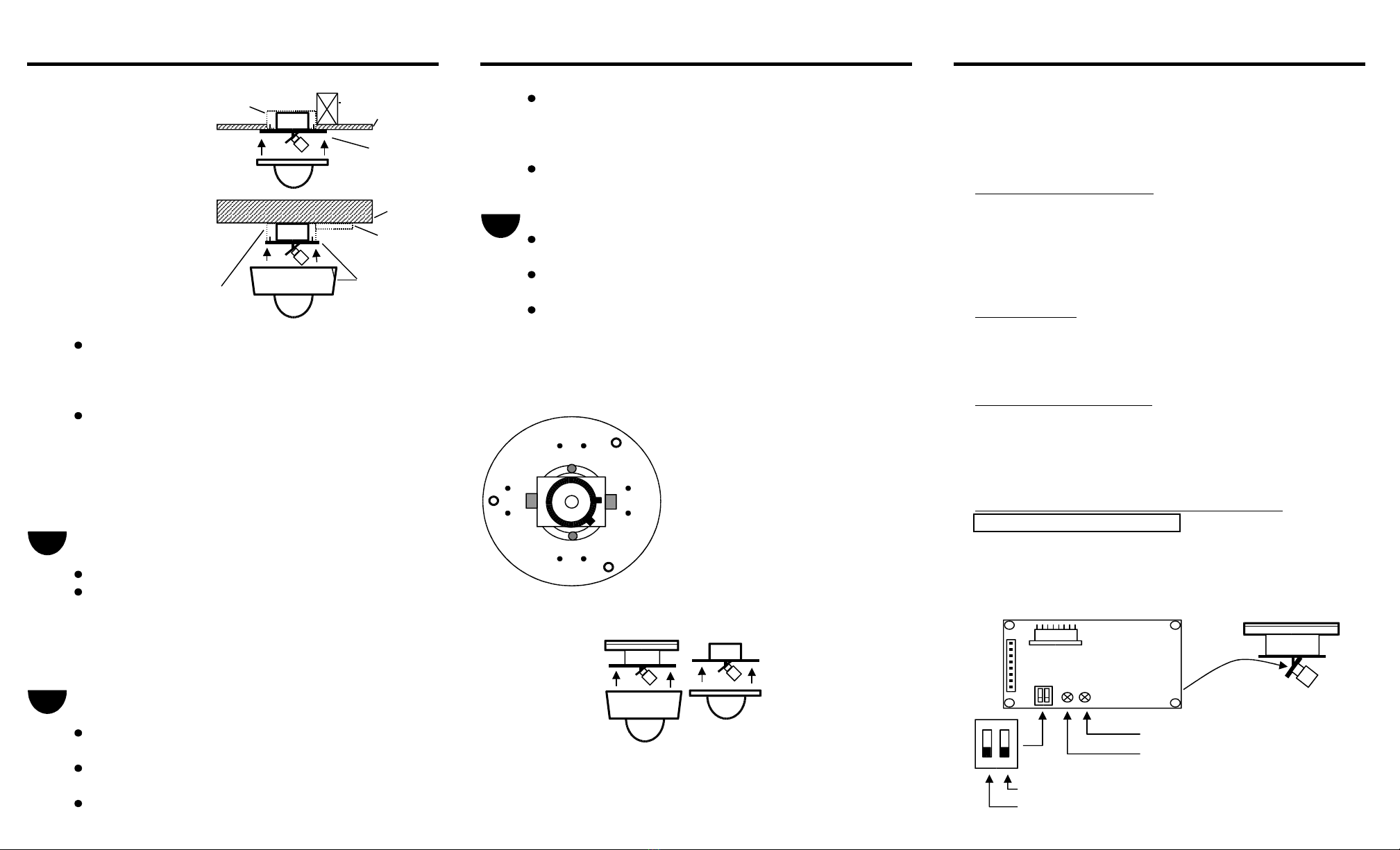

4-SQUARE FOR VARIFOCAL LENS:

ELECTRICAL BOX RAFTER Loosen the focal length an focus locking screws. A just accor ing ALL ADJUSTMENTS ARE MADE AT THE FACTORY FOR OPTIMAL

enclosure an mount CEILING to scene etail. Re-tighten the focal length an focus locking screws. PERFORMANCE. THE FOLLOWING SETTINGS SHOULD ONLY BE USED IF

in a 4-square electrical THESE ADJUSTMENTS DO NOT MEET THE REQUIREMENTS OF THE LOCATION

gang box in the ceiling FLUSH DOME FOR FIXED LENS: CONDITIONS.

MOUNT If the lens is out of focus, loosen lens set screw an turn clockwise

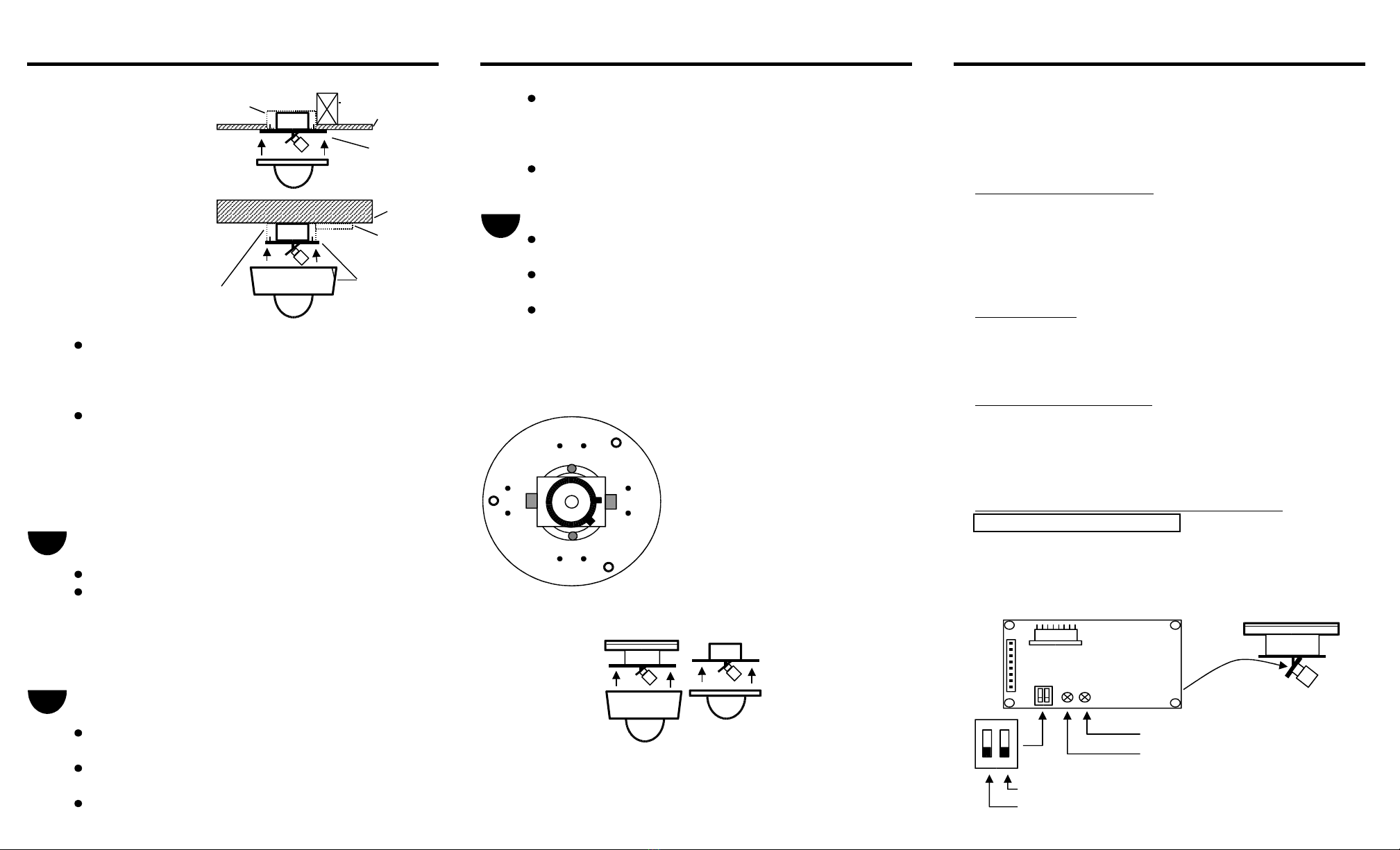

VERTICAL PHASE (LINE LOCK)

SOLID SURFACE To synchronize multiple cameras an prevent vertical

mount chassis an INSTALLING DOME & TRIM RING roll, a just the vertical phase (line-lock).

surface ome cover CONDUIT Be sure that all sealing washers are in place before mounting the trim See following iagrams for location of potentiometer. Turn

in a 4-square electrical gang an ome cover. the potentiometer clockwise or counter-clockwise using a

box on a soli surface FLUSH MOUNT Place ome over mounting plate. The screw holes will self-align. small screw river.

4-SQUARE CHASSIS AND The trim ring will "set" into place when holes are aligne .

ELECTRICAL SURFACE DOME Tighten the tamper-proof screws using the supplie L-Wrench. AUTO IRIS LEVEL

BOX COVER (This L-Wrench is not stan ar esign, keep it for further use) Turn DC IRIS LEVEL control clockwise or counter-clockwise to a just the

Pull the power an vi eo wires into the 4-square electrical box or light level. (FOR CAMERAS WITH AN AUTO-IRIS LENS) The location of the

in through the base of the surface mount enclosure. If necessary, potentiometer is note in the iagrams following.

attach con uit to the base of the enclosure an pull the wire in.

TOP VIEW BACK LIGHT COMPENSATION

Mount the enclosure on a surface using the appropriate 1. SELF ALIGNING SCREW HOLES (3) Back light compensation (on) will allow the camera to filter out high gain backgroun

har ware. Puncture the sealing washers with the mounting screws. 2. MOUNTING HOLES FOR DOUBLE

(Do not remove the sealing washers from the mounting holes) GANG BOX OR SURFACE MOUNT (8) on the CCD boar will provi e a justments for BLC (back light compensation).

If you are mounting irectly to a wall or ceiling, it is recommen e 3. CAMERA MOUNT BASE AND See following iagrams for the location of this switch.

that you use 1/4x20-inch hex-hea bolts with wall anchors in high PAN SCREWS

van alism applications. If you are mounting to a 4-square electrical 4. CAMERA MOUNT TILT SCREWS CAMERA DIP SWITCH / POTENTIOMETER SETTINGS

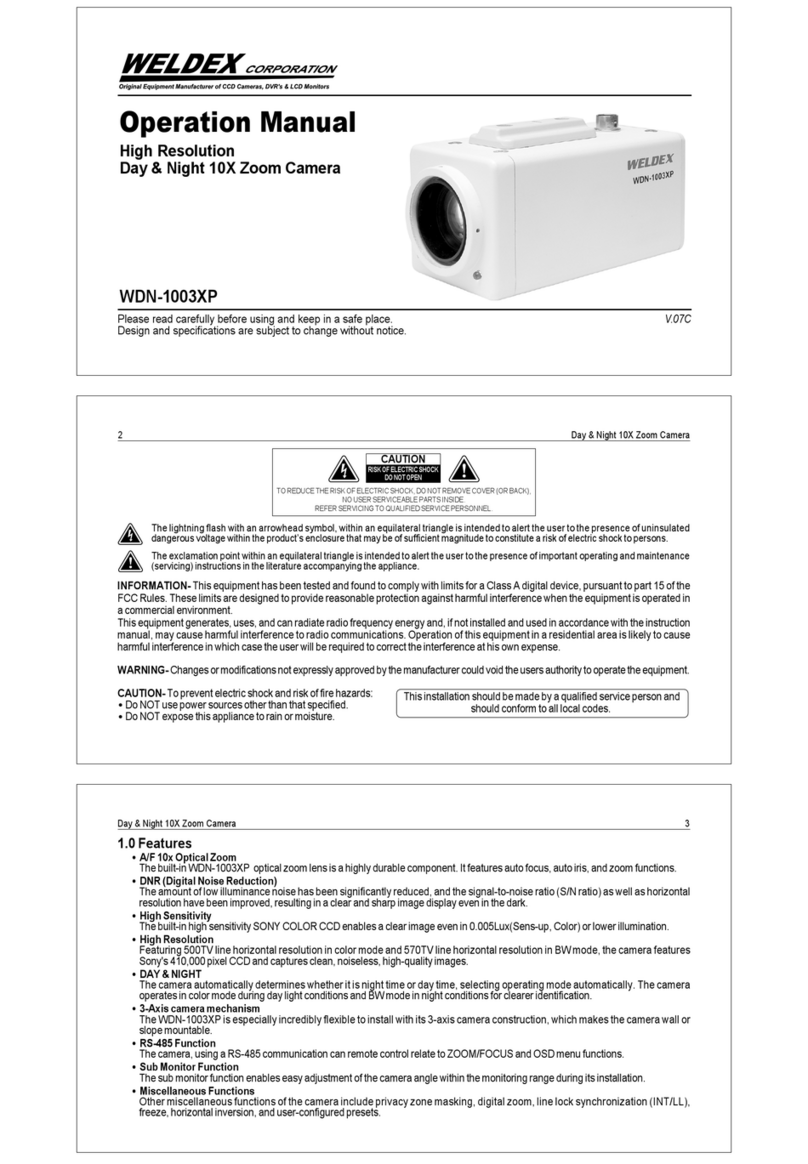

gang box, use 4 each 8-32 screws. 5. VARIFOCAL LENS LOCKING SCREWS DSP COLOR

6. SURFACE MOUNT TRIM RING AND SURFACE MOUNT WDDS - 2400S

CONNECT THE VIDEO AND POWER DOME WDDS - 2405S

Connect the vi eo cable to the BNC connector. 7. FLUSH MOUNT TRIM RING AND FLUSH MOUNT WDDF - 2400F

Depen ing on the power requirement of the camera (AC24V or DC12V), DOME WDDF - 2405F

connect the power wires to the appropriate input wires.

SIDE VIEW

CAUTION

BE SURE TO CONNECT THE CORRECT POLARITY TO

THE CORRECT WIRE INPUT ON CAMERAS REQUIRIN DC12V. 6 7 LOCATED

ON BACK OF BOARD

ADJUSTING THE CAMERA AND LENS

Loosen the camera mount tilt screws. Loosen the camera mount DC IRIS LENS LEVEL

pan an base screws. LINE - LOCK (PHASE)

A just the camera to the proper pan position an tighten

own the camera mount pan an base screws. SEE SPECIFICATION SHEET FOR FURTHER DETAILS ON PARTICULAR MODELS. BLC MODE (ON / OFF)

A just the camera to the proper tilt position an tighten ELECTRONIC IRIS (ON - AE / OFF - ME)

B. Use the flush

or conterclockwise to focus.

C. Use the flush

light to obtain forgroun etails. Switches on the ip switch mo ule locate

2 1

3

4

2

3

4

ON

1 2