Westward Heavy Duty

Transmission Jack

Operating Instructions & Parts Manual 1VW35

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself

and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions

for future reference.

®

Description

Westward heavy duty hydraulic transmission jack is designed for lifting and lowering of

transmissions and differentials from various vehicles ie. car, truck, etc.. They feature a

wide base to reduce center of gravity and promote stability. Their super strong

reinforced steel construction with flanged side frames provide extra strength. Load

restraining chains help to assure the user’s safety when lifting and lowering load. Four

casters allow easy movement, and easy positioning of transmission jack. The cradle

has both side and tilting angle adjusting functions to best fit onto the different shapes of

various transmissions and differentials. Patented oil by-pass mechanism offers stroke

limitation of ram piston. Durable rust-free enamel finish gives long-lasting quality

appearance. Metered release valve assures precise adjustment of cradle height and

smooth lowering of load.

Specifications

Min. Max. Power

Model Capacity Height Height Raise

1VW35 1-1/2Ton 7-7/8" 37-1/4" 29-3/8"

General Safety Information

Study, understand

and follow all

instructions before operating this device.

Lifting device only. Intended use is for

removing, transporting and installing

transmission or specified components

only. Do not lift or support a vehicle with

a transmission jack. Immediately after

lifting, support vehicle with appropriate

means. Do not exceed rated capacity.

Use only on hard, level surfaces capable

of sustaining rated capacity loads. Always

wear safety glasses when using this

equipment. Inspect jack before each use.

Do not use if bent, broken, leaking or

damaged components are noted. No

alteration of this product is allowed.

Do not use this device for any purpose

other than that for which it was intended .

Failure to heed any one or combination of

these warnings may result in severe

personal injury and/or property damage.

Assembly

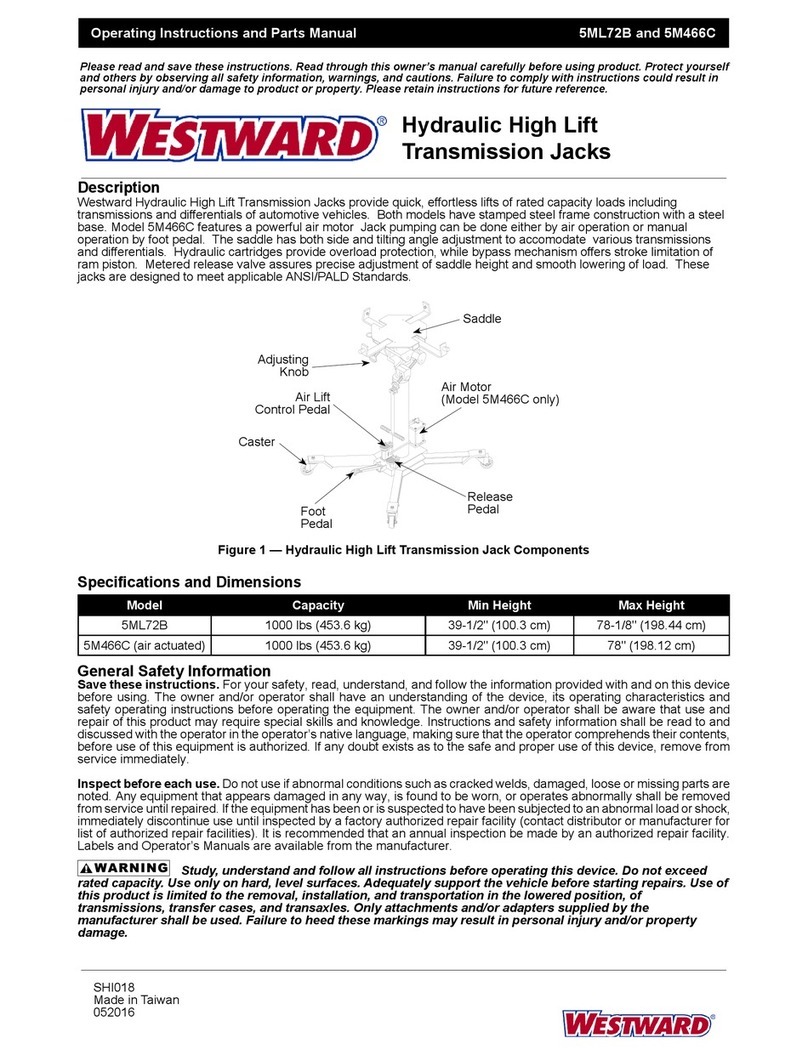

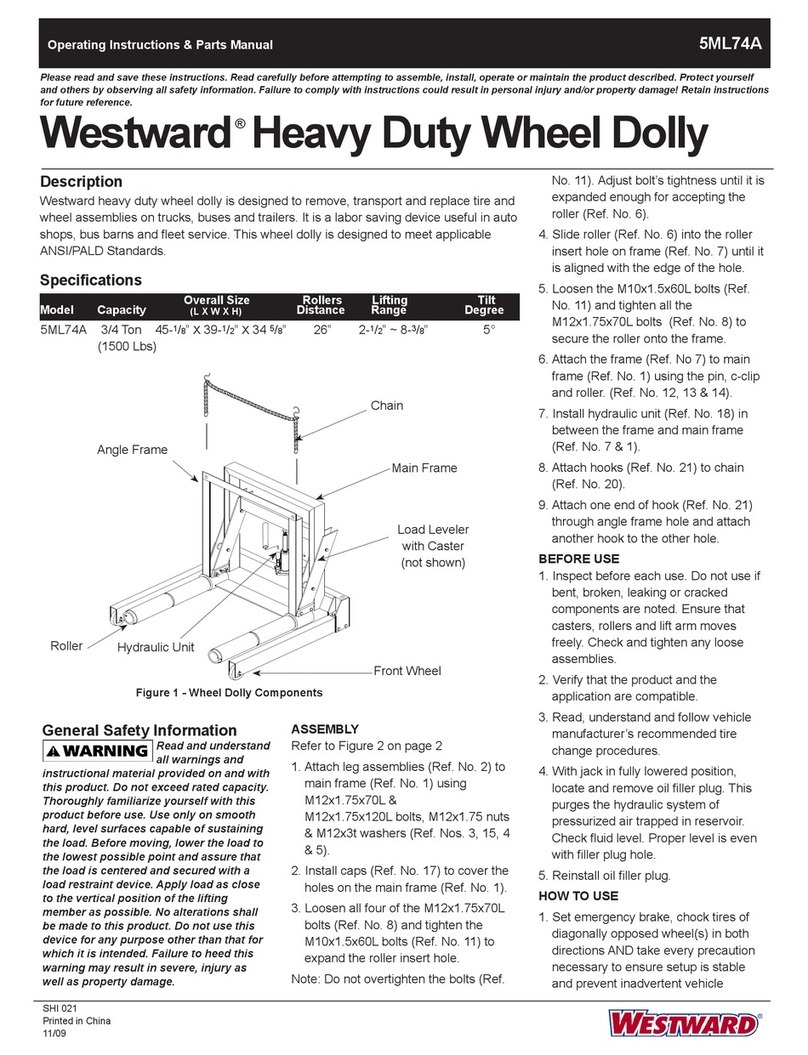

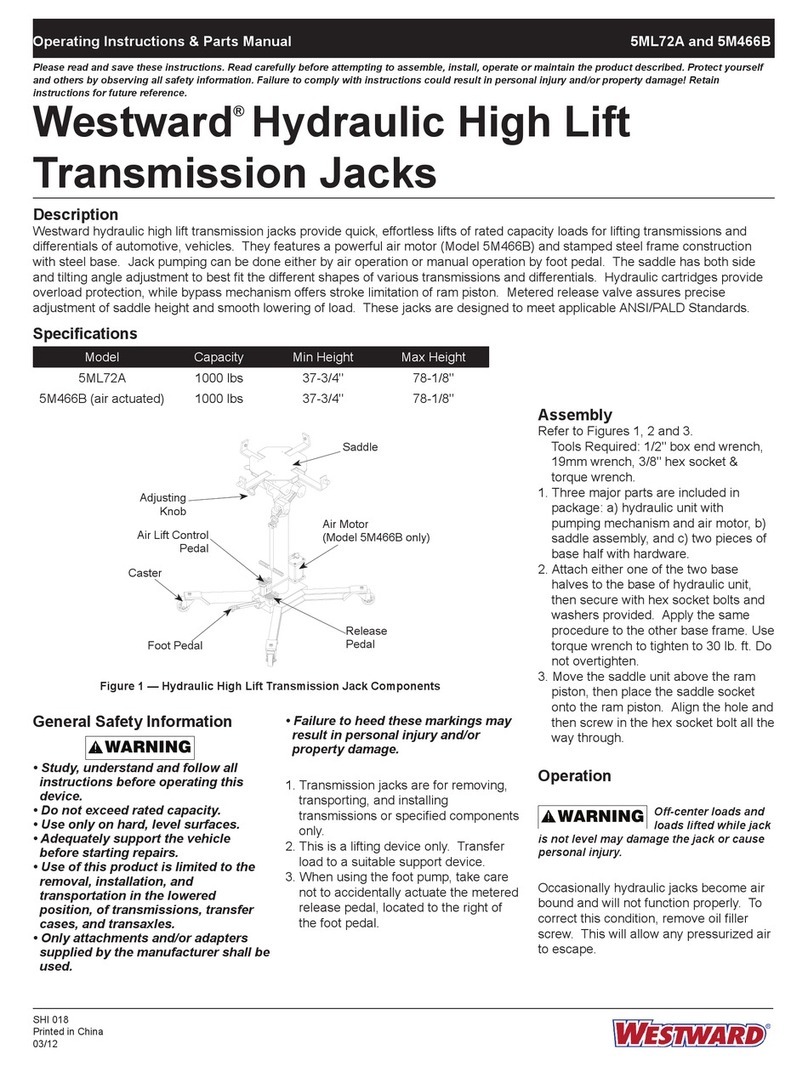

Refer to Figure 1.

1. Four pieces of auxiliary fixed

assemblies and a one-piece handle

should be included in package.

2. Attach either one of the four auxiliary

fixed assemblies to the cradle, and

secure by hex bolts and washers

provided. Then apply the same

procedure for the other assembly.

3. Occasionally hydraulic jacks become

air bound and will not function properly.

To correct this condition, remove oil

filler screw. This will allow any

pressurized air to escape.

4. Check for proper oil level (See adding

oil, Page 2), adjust as needed. DO

NOT OVERFILL. Reinstall oil filler

screw.

Operation

Off-center loads and

loads lifted while jack

is not level may damage the jack or cause

personal injury.

REMOVING TRANSMISSION/

DIFFERENTIAL FROM VEHICLE

1. Close the release valve by turning the

release knob clockwise.

2. Raise the jack by pumping the jack

handle until desired height is acheived.

3. Adjust the cradle side position and

tilting angle to best fit to the shape of

transmission/differential.

4. Secure the transmission/differential by

chain and tighten properly.

5. After removing all of the appropriate

bolts and fasteners which secure the

load to vehicle, carefully lower the load

to the lowest practical height. Move

load to desired workplace.

LIFTING TRANSMISSION /

DIFFERENTIAL INTO VEHICLE

1. Place transmission/differential on jack

cradle and properly secure by chain.

2. Move jack/transmission into location.

3. Cautiously pump jack handle to lift up

the transmission/differential to desired

height.

SHI 025

Printed in Taiwan

03/10

Caster

Saddle

Chain

Handle

Release Knob

Adjusting Knob

Figure 1 — Hydraulic Transmission Jack Components

Oil Filler Screw