Operation

Operation

Off-centered loads

and loads lifted while jack is not level

may damage the jack or cause personal

injury.

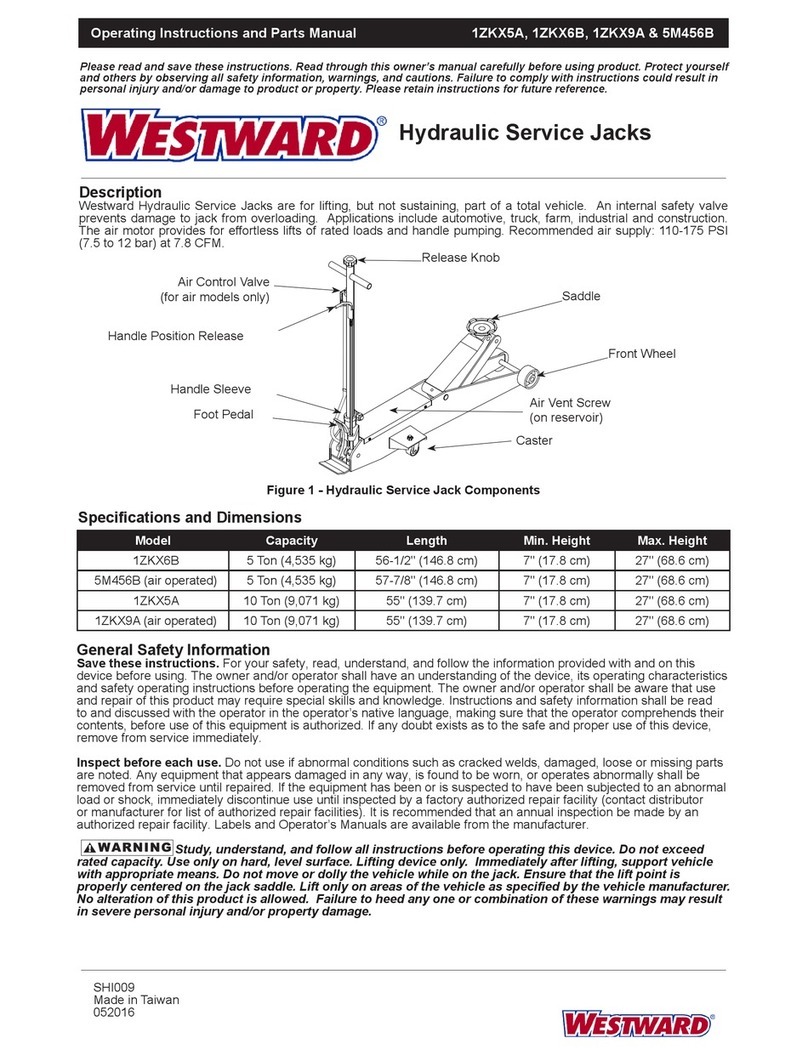

RAISING VEHICLE

1. Make sure the jack and vehicle are on a

hard level surface.

2. Always set the vehicle parking brake

and block the wheels.

3. Consult the vehicle owners manual to

ascertain the location of lift points and

position the jack under the prescribed

lift point.

4. Turn the release valve clockwise to the

closed position. Do not over tighten!

5. To raise the vehicle to desired height,

place the handle into the socket and

pump up and down.

6. Place jack stands beneath the vehicle

at locations recommended by the vehi-

cle manufacturer. Do not get under the

vehicle without jack stands. Jacks are

not designed to maintain heavy loads

for long periods of time.

7. Turn release valve slowly counterclock-

wise to lower load onto jack stands.

This is a lifting

device only. The load must be support-

ed immediately by other appropriate

means. Keep hands, feet, and clutter

clear of ground area when lowering

the load.

LOWERING VEHICLE

1. Turn the release valve clockwise to the

closed position.

2. Pump the handle to lift vehicle off of

jack stands

3. Remove the jack stands. Do not get

under or let anyone else under the vehi-

cle while lowering.

4. Turn the release valve SLOWLY coun-

terclockwise to lower the vehicle onto

the ground.

Avoid shock loads

created by quickly opening and closing

the release valve as the load is being

lowered. Shock loads can create dan-

gerously high operating pressures

within the hydraulic system, causing

system failure and resulting in personal

injury and/or property damage.

Inspection

The product shall be maintained in accor-

dance with the product instructions. No

alterations shall be made to this product.

1. The product shall be inspected immedi-

ately if the jack is believed to have been

subjected to an abnormal load or shock.

It is recommended that this inspection

be made by an authorized customer

service representative prior to use.

2. Repair of this equipment requires spe-

cialized knowledge and facilities. If the

jack is subjected to abnormal load or

shock, remove from service and have it

examined by an authorized inspection

facility for parts or repairs. An annual

inspection of the product should be

made by a manufacturer’s authorized

repair facility. Any defective parts,

decals, or safety labels shall be

replaced with manufacturer’s specified

parts.

Maintenance

Monthly maintenance is recommended.

Lubrication is critical to jacks as they sup-

port heavy loads. Any restriction due to

dirt, rust, etc., can cause either slow

movement or extremely rapid jerks, dam-

aging the internal components. The follow-

ing steps are those designed to keep the

jack well lubricated:

1. Lubricate the ram, linkages, saddle and

pump mechanism with light oil. Grease

wheel bearings and axles.

2. Visually inspect for cracked welds, bent,

loose, missing parts or hydraulic oil

leaks.

3. If jack is subjected to abnormal load or

shock, remove from service and have it

examined by an Authorized Repair

Service.

4. Clean all surfaces and maintain all

labels and warnings.

5. Check and maintain the ram oil level.

IMPORTANT: Do not use brake or trans-

mission fluids, or regular motor oil as

they can damage the seals. Always pur-

chase and use products labeled

Hydraulic Jack Oil.

CHECKING OIL

1. Turn handle counterclockwise to allow

ram to fully retract. It may be necessary

to apply force to the saddle for lowering.

2. With jack in upright position remove oil fill

plug. Oil should be even with bottom of

hole. If not, top up. Do not overfill. Always

fill with new, clean hydraulic jack oil.

3. Replace fill plug.

4. Check jack operation.

CHANGING OIL

For best performance and longest life,

replace the complete fluid supply at least

once per year.

1. With saddle fully lowered and pump pis-

ton fully depressed, remove the fill plug.

2. Lay the jack on its side and drain the

fluid into a suitable container.

NOTE: Dispose of hydraulic fluid in accor-

dance with local regulations.

3. Fill with good quality hydraulic oil, rein-

stall the fill plug.

LUBRICATION

1. Applying a coating of light lubricating oil

to pivot points, axles and hinges will

help to prevent rust and assure that

wheels, casters and pump assemblies

move freely.

2. Periodically check the pump piston and

ram for signs of rust or corrosion. Clean

as needed and wipe with an oily cloth.

NOTE: Never use sandpaper or abrasive

material on these surfaces !

SYSTEM AIR PURGE

1. Turn release valve counterclockwise one

full turn to open.

2. Pump handle eight full strokes.

3. Turn release valve clockwise to close

valve.

4. Pump handle until the lift arm reaches

maximum height and continue to pump

several times to remove trapped air in

the ram.

5. Carefully and slowly pinch oil fill plug to

release trapped air.

6. Turn release valve counterclockwise one

full turn and lower lift arm to the lowest

position. Use force if necessary.

7. Turn release valve clockwise to closed

position and check for proper pump

action. It may be necessary to perform

the above more than once to assure air

is evacuated totally.

Storage

Always store your jack in the fully lowered

position. This will protect critical areas

from excessive corrosion.

Alterations

Because of the potential hazards associat-

ed with the misuse of this type of equip-

ment, no alterations shall be made to the

product without written authorization of the

manufacturer or supplier.

2

Operating Instructions & Parts Manual 1MZK7

HHyyddrraauulliicc22..55TToonnSSppiiddeerrJJaacckk