Westward Hydraulic

Toe Jacks

Operating Instructions & Parts Manual 1AVP7 and 1VW31

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself

and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions

for future reference.

®

Description

Westward hydraulic toe jacks are designed for lifting, but not sustaining rated capacity

loads. There are designed to be used vertically. These jacks are suitable for use to lift

up heavy objects with low ground clearance. It is not recommended for use in lifting or

positioning houses or building. These jacks are designed to meet or exceed ANSI/

PALD Standards.

Specifications

Head Saddle Toe Saddle

Model Capacity Base Size Lifting Range Lifting Range

1VW31 5 Ton 7-1/2"x 4-5/8" 10-1/2" to 15-5/8" 7/8" to 5-3/4"

1AVP7 10 Ton 11-5/8"x 9-1/4" 11" to 16-1/8" 1-1/8"to 6-1/4"

General Safety Information

Study, understand,

and follow all

instructions before operating this device.

This is a lifting device only. Intended use

is for lifting part of a total vehicle, only one

wheel or axle at a time. Immediately after

lifting, support vehicle with appropriate

means. Do not exceed rated capacity. Use

only on a hard level surface capable of

sustaining rated capacity loads. Lift only

on those areas of the vehicle as specified

by the vehicle manufacturer. Ensure that

the lift point is properly centered on the

jack saddle. Always wear safety goggles

when using this equipment. Inspect jack

before each use. Do not use if bent,

broken, leaking, or damaged components

are noted. No alteration of this product is

allowed. Do not use this device for any

purpose other than that for which it was

intended. Failure to heed any one or

combination of these warnings may result

in severe personal injury and/or property

damage.

Before Use

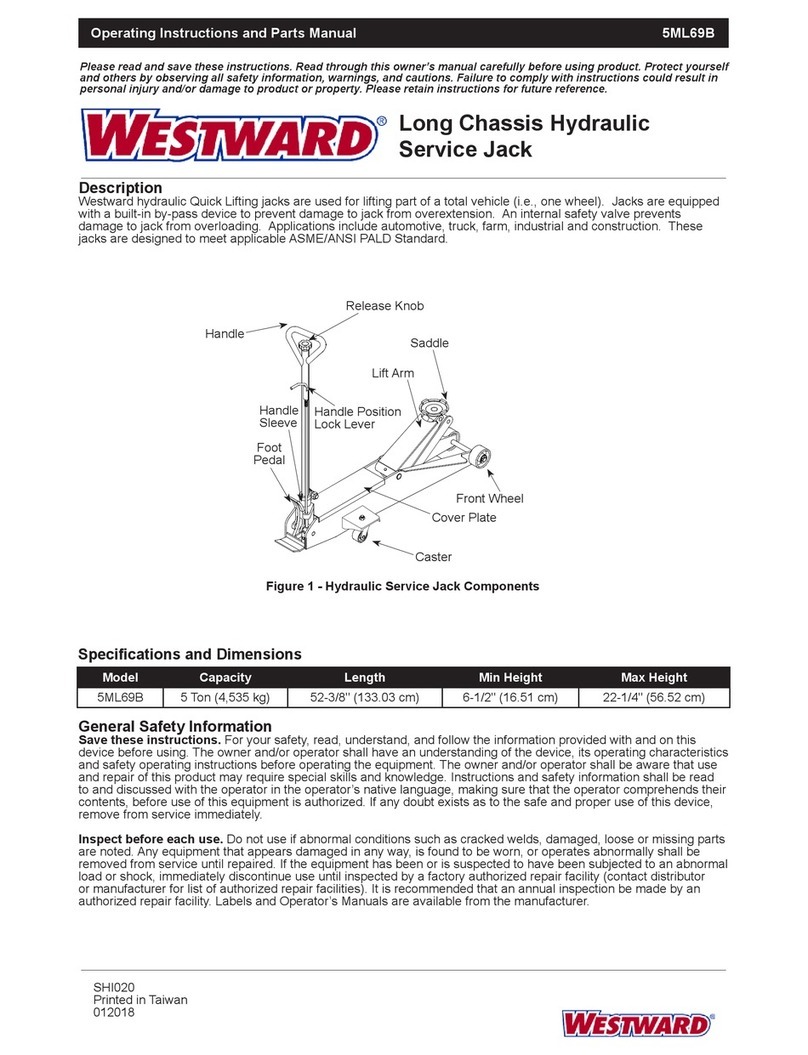

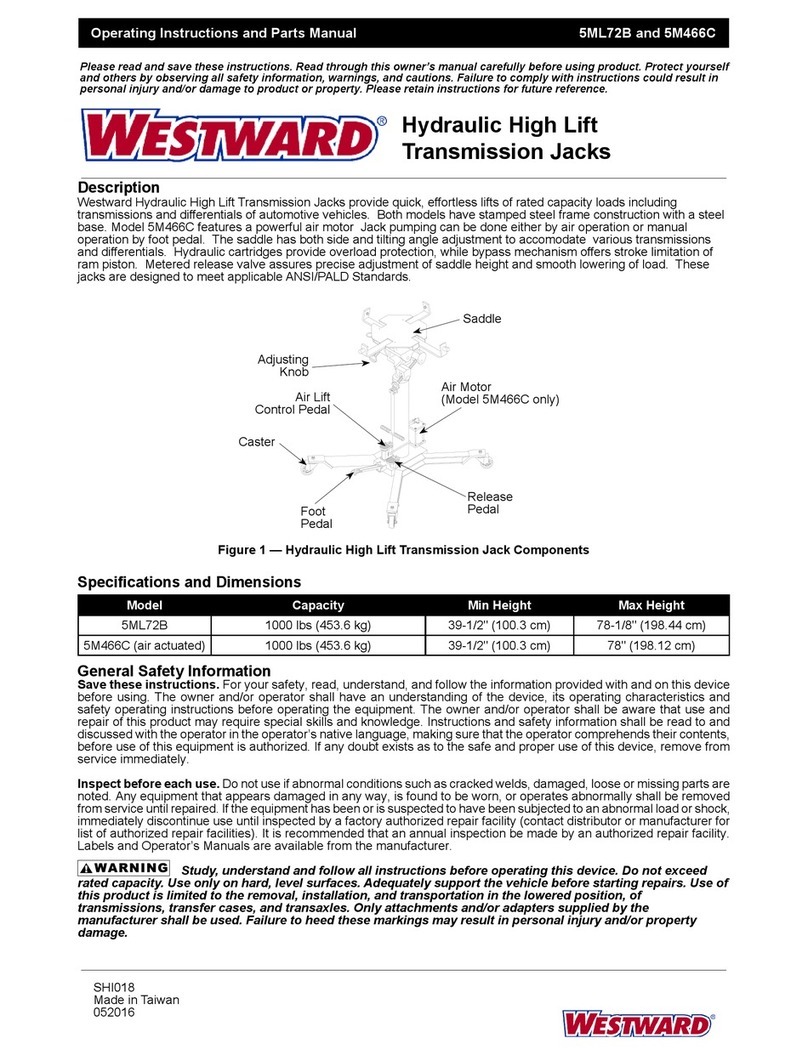

Use figure 1 as reference.

1. Occasionally hydraulic jacks become

air bound and will not function properly.

To correct this condition, remove oil

filler screw. This will allow any

pressurized air to escape.

a. Ensure the oil level is even with or

just below the oil filler hole.

b. Reinstall the oil filler screw.

2. Thoroughly lubricate all moving parts

of the jack.

3 With notched end of the handle, close

release valave by turning it clockwise

firmly and pump saddle to fully

extended, then open release valve to

lower the saddle.

Operation

LIFTING

1. Assemble 3-piece handle by lining up

spring pins with corresponding slots.

2. Secure load to prevent inadvertent

shifting and movement.

3. Close release valve by turning handle

clockwise until it is firmly closed.

4. Position jack under load and pump

handle until saddle contacts load.

Off center loads

and loads lifted while

jack is not level may damage the jack or

cause personal injury.

5. Raise load to desired height and

immediately transfer load to proper

mechanical means such as jack

stands.

LOWERING

Be sure all tools

and personnel are

clear before lowering load.

1. Insert handle onto release valve and

slowly turn handle counterclockwise no

more than half full turn at a time.

2. Push handle sleeve down manually if

still extended to reduce piston

exposure to rusting

IMPORTANT: Avoid “shock load” created

by quickly opening and closing the

release valve as load is being lowered.

This may result in an overloading of the

hydraulic circuit and possible damage to

the jack.

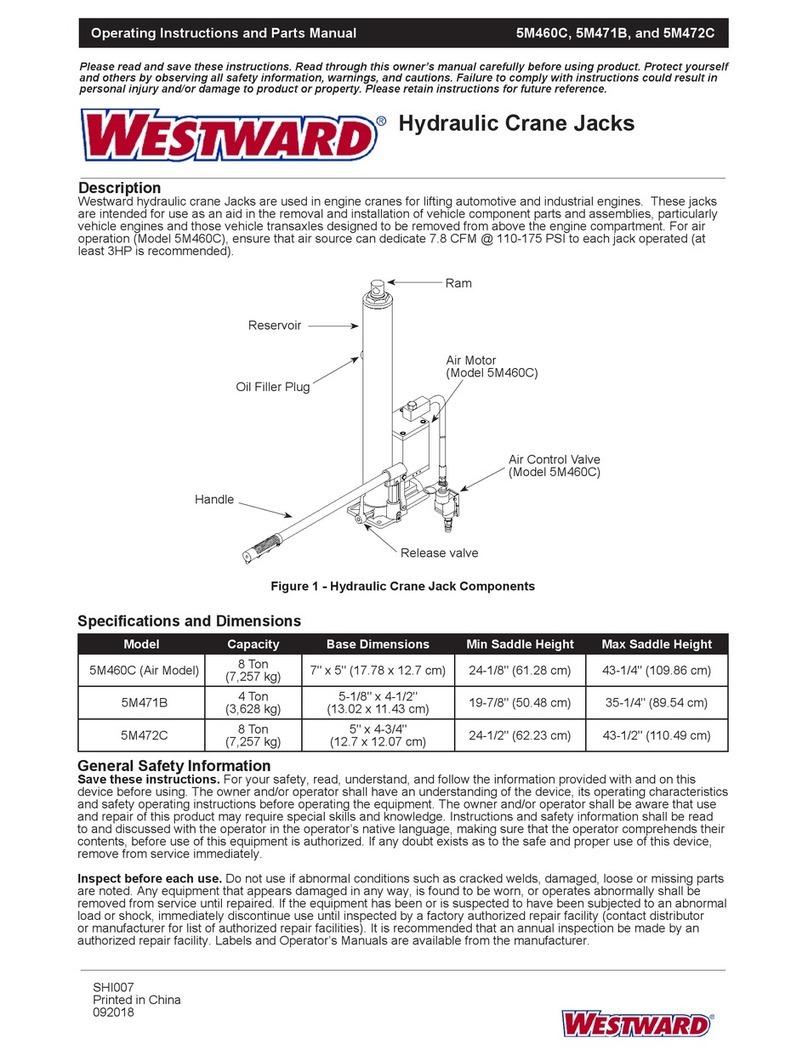

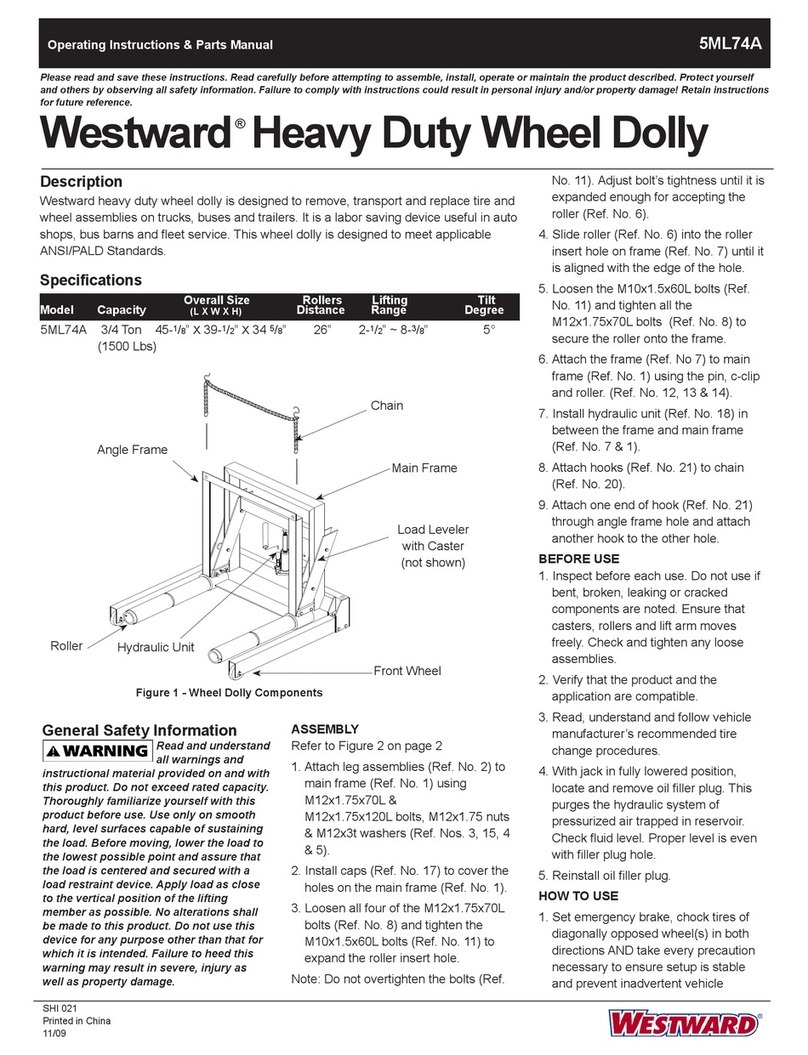

Figure 1- Hydraulic Toe Jack Components

Handle

Toe Saddle

Head Saddle

Release Valve

Base

Handle Sleeve

SHI 034

Printed in Taiwan

03/10

Oil Filler Screw

(not shown)