3

HEAT MODE

In a typical system, a call for first stage heat is initiated by

closing the W1 thermostat contacts. The Humidifier output is

energized and the inducer blower is enabled at low speed. The

control waits for the stage 1 pressure switch to close. When

the pressure switch closes the silicon nitride ignitor is powered.

This control has an adaptive algorithm that reduces the ignitor

temperature to slightly greater than the minimum temperature

required to ignite gas in each particular application. The con-

trol measures the line voltage and determines an initial ignitor

temperature setting based on the measurement. After each

successful ignition, the control lowers the ignitor temperature

slightly for the next ignition attempt. The control continues to

lower the ignitor temperature until ignition does not occur, and

the control goes into retry mode. For the second attempt to

ignite gas within the same call for heat, the control increases

the ignitor temperature to the value it was on the previous

successful ignition. After ignition is successful, the control sets

the ignition temperature at this value. The control is constantly

making adjustments to the ignitor modulation routine to com-

pensate for changes in the line voltage. The control will relearn

after power interruptions.

The Silicon Nitride ignitor manufactured by White-Rodgers

must be used.These ignitors are specially designed to operate

with the adaptive ignition routine used by the control to ensure

the most efficient ignitor temperature.

At the end of the ignitor warm-up time, the first stage of the two-

stage manifold gas valve is energized (low fire). Flame must be

detected within 5 seconds. If flame is detected, the 45 second

delay-to-fan-on period begins. After the delay-to-fan-on period

ends, the circulator enable, (pin 15 on the 16-pin connector is

the “E” output to the circulator) and air cleaner are energized.

A call for second stage heat (W1 and W2) after a call for first

stage heat will activate a 30-second 2nd stage delay. Following

the 30-second delay, the inducer motor is driven at high speed.

The control checks the 2nd stage pressure switch. When the

pressure switch closes, the 2nd stage gas valve turns on and

the circulator is enabled at high speed (“E” remains energized

any time the circulator is on).

When the second stage of the thermostat is satisfied, the inducer

motor is reduced to low speed, and the 2nd stage gas valve and

high circulator speed are de-energized.

When the first stage of the thermostat is satisfied, the gas valve

is de-energized and the heat delay-to-fan-off timing begins.The

inducer will postpurge for an additional 5 seconds. When this

time is expired, the inducer and humidifier will de-energize.Upon

completion of the heat delay-to-fan-off period, the circulator and

air cleaner are de-energized.

If flame is not detected during the trial-for-ignition period, the gas

valve is de-energized, the ignitor is turned off, and the control

goes into the “retry” sequence.

The “retry” sequence starts with a 60-second interpurge, en-

abling the inducer at low speed for 60 seconds following an

unsuccessful ignition attempt (flame not detected). After this

wait, the ignition sequence is restarted. If this ignition attempt

is unsuccessful, one more retry will be made before the control

goes into system lockout.

If flame is detected, then lost, the control will repeat the initial ig-

nition sequence for a total of ten “recycles”.After ten unsuccessful

attempts to sustain flame, the control will go into system lockout.

During burner operation, a momentary loss of power of 250

milliseconds or longer will de-energize the main gas valve.When

power is restored, the gas valve will remain de-energized and a

restart of the ignition sequence will begin immediately.

A momentary loss of gas supply, flame blowout, or a shorted or

open condition in the flame probe circuit will be sensed within

2 seconds. The gas valve will de-energize and the control will

restart the ignition sequence.Recycles will begin and the burner

will operate normally if the gas supply returns, or the fault con-

dition is corrected, before the last ignition attempt. Otherwise,

the control will go into system lockout.

If the control has gone into system lockout, it may be possible

to reset the control by a momentary power interruption of five

seconds or longer. Refer to PRECAUTIONARY, SYSTEM

LOCKOUT, AND DIAGNOSTIC FEATURES.

COOL MODE

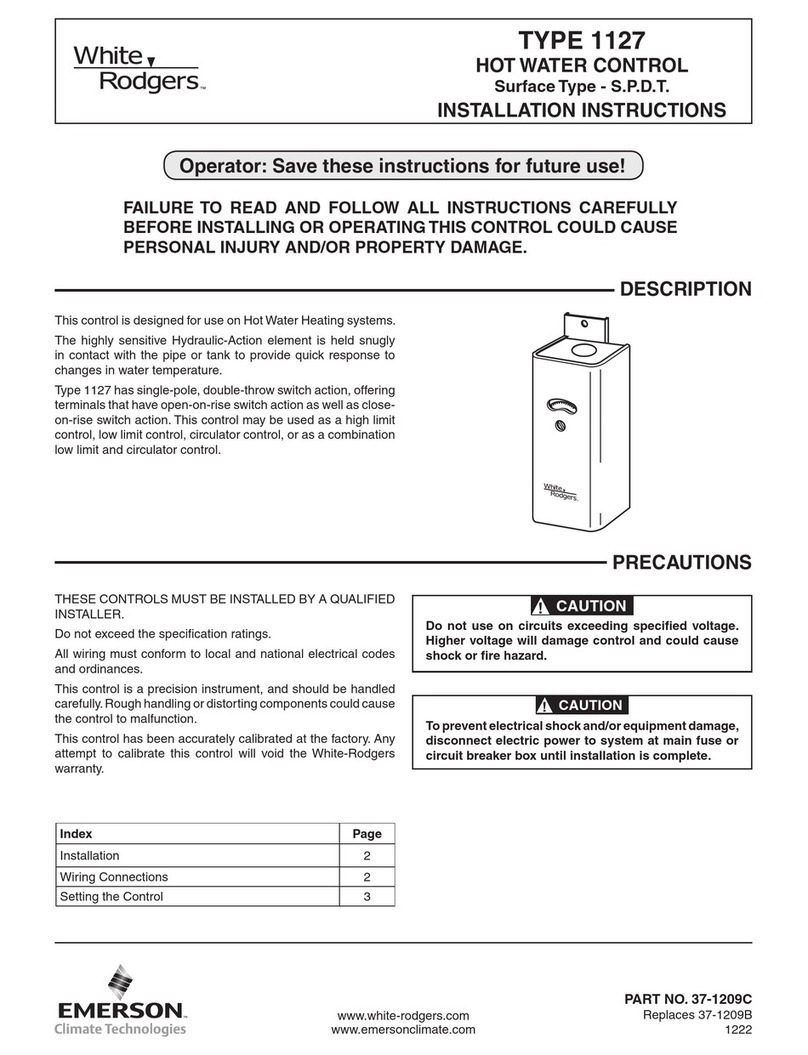

In a typical system, a call for cool is initiated by closing the

thermostat contacts. This energizes the compressor, circulator

“E” output and air cleaner. After the thermostat is satisfied, the

compressor is de-energized and the optional cool mode delay-

to-fan-off period begins.After the optional delay-to-fan-off period

ends, the circulator “E” output and air cleaner are de-energized.

MANUAL FAN ON MODE

If the thermostat fan switch is moved to the ON position, the

circulator “E” output and air cleaner are energized. When the

fan switch is returned to the AUTO position, the circulator “E”

output and air cleaner are de-energized.

PRECAUTIONARY, SYSTEM LOCK-

OUT, AND DIAGNOSTIC FEATURES

PRECAUTIONARY FEATURES

The following precautionary features are built into the control.

1. If the high temperature limit or flame rollout sensor open

at any time, the gas valve is de-energized.

2. During a call for heat cycle, if flame is sensed at any time

when the gas valve is de-energized, the circulation “E”output

and inducer fan are energized at low speed in conjunction

with system lockout.

3. If the high limit (and/or auxiliary limit) switch(es) open at

any time during a call for heat, the circulator blower and

inducer fan are energized at low speed.

SYSTEM LOCKOUT FEATURES

When system lockout occurs, the gas valve is de-energized, the

circulator “E” output and the inducer blower are energized at low

speed.The diagnostic indicator light will flash to indicate system

status.(System lockout will never override the precautionary

features described above.)

To reset the control after system lockout, do one of the

following:

1. Interrupt the call for heat at the thermostat for at least one

second and less than twenty seconds (if flame is sensed

OPERATION