8WIKA operating instruction, models F7301, F73C1, F73S1

EN

14522216.01 11/2023 EN/DE

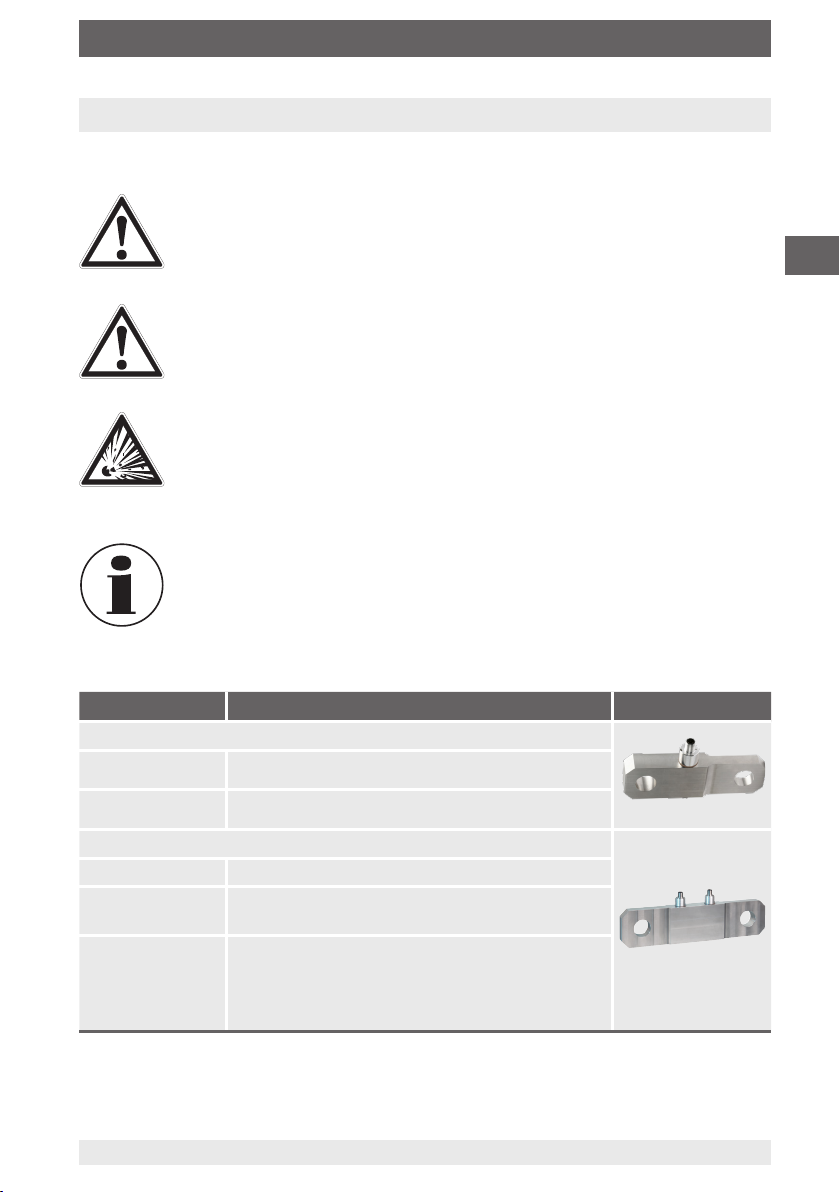

3. Safety

Tension links for measuring tension forces, for example in cranes.The product is

designed for use both outside and inside of buildings.

Tension links can measure forces in only one direction.The measured force is output

as an electrical signal.These devices are designed for operation in an industrial

environment. In other environments, e.g. residential or commercial, they may interfere

with other equipment. In this case, the operator may be required to implement

appropriate measures.

Only use the tension links in applications that are within the technical performance limits

(e.g. max. ambient temperature, material compability, etc.). For performance limits, see

Only the tensions links of models F73C1, version 1, are approved for use in hazardous

areas! For Ex instruments, please note the additional information to this operating

instruction (article number 14537280). For an overview, see the table on page 7.

The tensions links are designed exclusively for the intended use which is described here

and may only be used accordingly. Claims of any kind due to improper use are excluded.

observed. Improper handling or operation of the instrument outside of its technical

inspected by an authorised service engineer.

Handle electronic precision measuring instruments with the required care (protect from

do not insert any objects into the instrument or its openings). Plugs and sockets must be

protected from contamination.

The tension links are intended for use in stationary large tools, large systems and

moving machines. The tension/compression force transducers are therefore excluded

from the scope of the EU Directive 2011/65/EU (RoHS); see 2011/65/EU, Article 2

(4) d), e) and g) and thus also to the Restriction of the Use of Certain Hazardous

Substances in Electrical and Electronic Equipment Regulations 2012 for UK, as that

corresponds to 2011/65/EU.

This instrument is intended to be connected to PELV external circuit compliant with

The manufacturer shall not be liable for claims of any type based on operation contrary